Fixed impeller and motor using same

A fixed impeller and blade technology is applied in the field of fixed impellers and motors using the fixed impellers, which can solve the problems of increasing the production cost of the whole vacuum cleaner, and achieve the effects of improving performance, reducing losses, and increasing suction air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

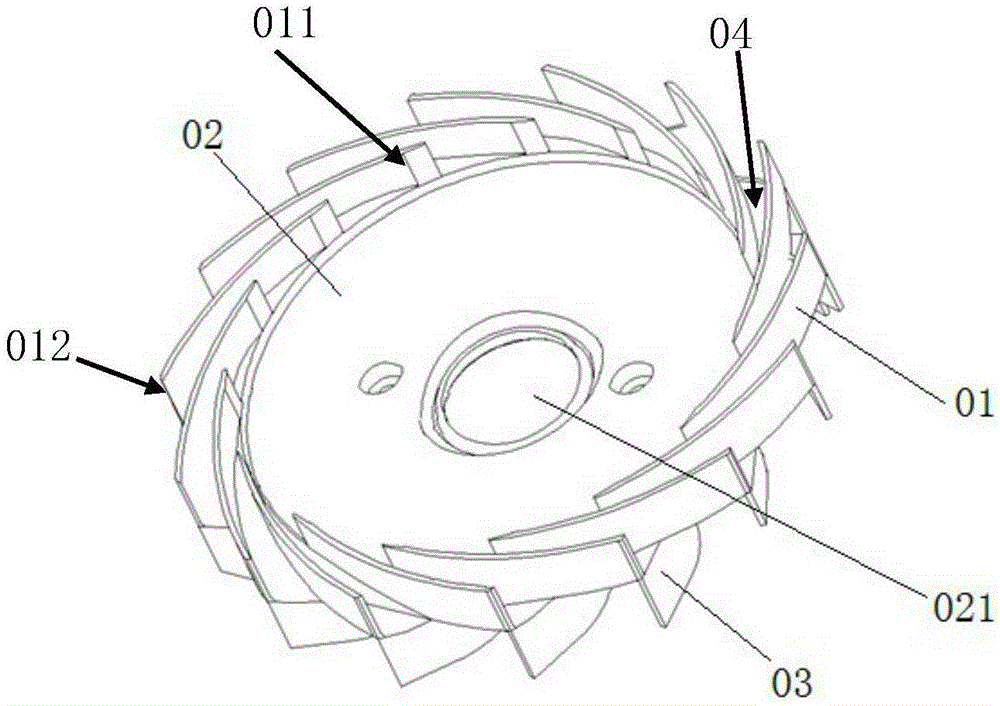

[0068] Please refer to Figure 4 The upper blade structure of the fixed impeller provided in this embodiment is shown in the figure. A fixed impeller includes a wind guide vane, and the wind guide vane includes an upper blade 11, a lower blade 13 and a base plate 12. The outer edge 111 of the upper blade is provided with a toothed structure, which can be provided with a toothed structure on the outer edge of some upper blades located at the air inlet, or can be provided with a toothed structure on the outer edge of all the upper blades located at the air inlet .

[0069] There is at least one tooth structure, and the shape of the tooth structure can be one of rectangle, V shape, trapezoid and involute shape.

[0070] The outer edge 111 of the air inlet of the upper blade is provided with a toothed structure 13, and the outer edge 12 of the air outlet of the upper blade 11 is not provided with a toothed structure. When the vacuum cleaner is working, air enters from the air inl...

Embodiment 2

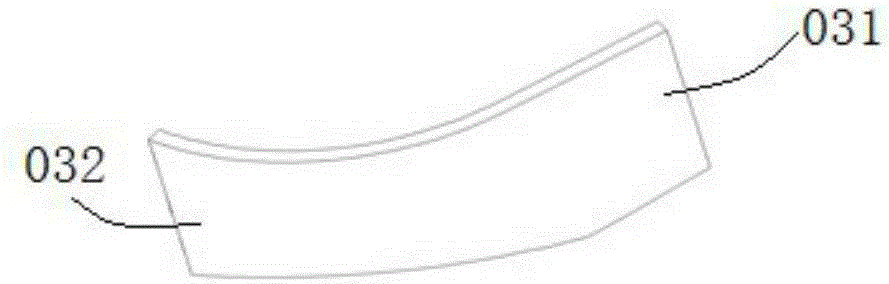

[0077] Please refer to Figure 10 , a fixed impeller, including a wind guide vane, the wind guide vane includes an upper blade 11, a lower blade 13 and a base plate 12, and a toothed structure 15 is provided on the outer edge 131 of the lower blade at the air inlet, which may be a part The outer edges of the lower blades located at the air inlet are provided with a toothed structure, or all the outer edges of the lower blades located at the air inlet are provided with toothed structures.

[0078] There is one or more than one tooth structure, and the shape of the tooth structure can be one of rectangle, V shape, trapezoid and involute shape.

[0079] One embodiment of the present invention is that the outer edge 132 of the lower blade at the air inlet is provided with a toothed structure 15, and the turbulent flow at the air inlet passes through the toothed structure 15 to be combed smoothly. The shape of the tooth structure 15 can be one of rectangle, V shape, trapezoid and ...

Embodiment 3

[0084] A fixed impeller includes a wind guide vane, and the wind guide vane is composed of upper blades, and tooth-shaped structures are provided on the outer extension edges of the upper blades at the wind inlet and / or wind outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com