Delayed action spring force element for nasal dilators

A nasal dilator and spring force technology, applied in the field of spring force components used for delayed action of nasal dilators, can solve the problems of nasal dilator detachment, insufficient viscosity to offset the spring force of external nasal dilators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

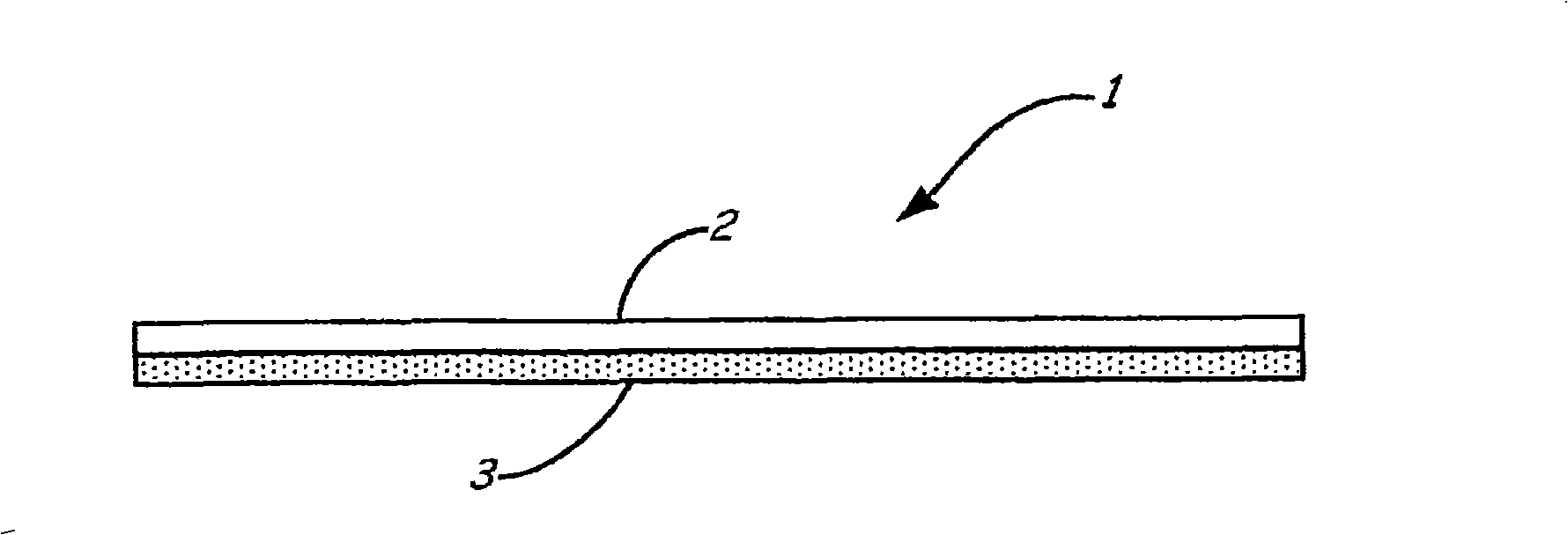

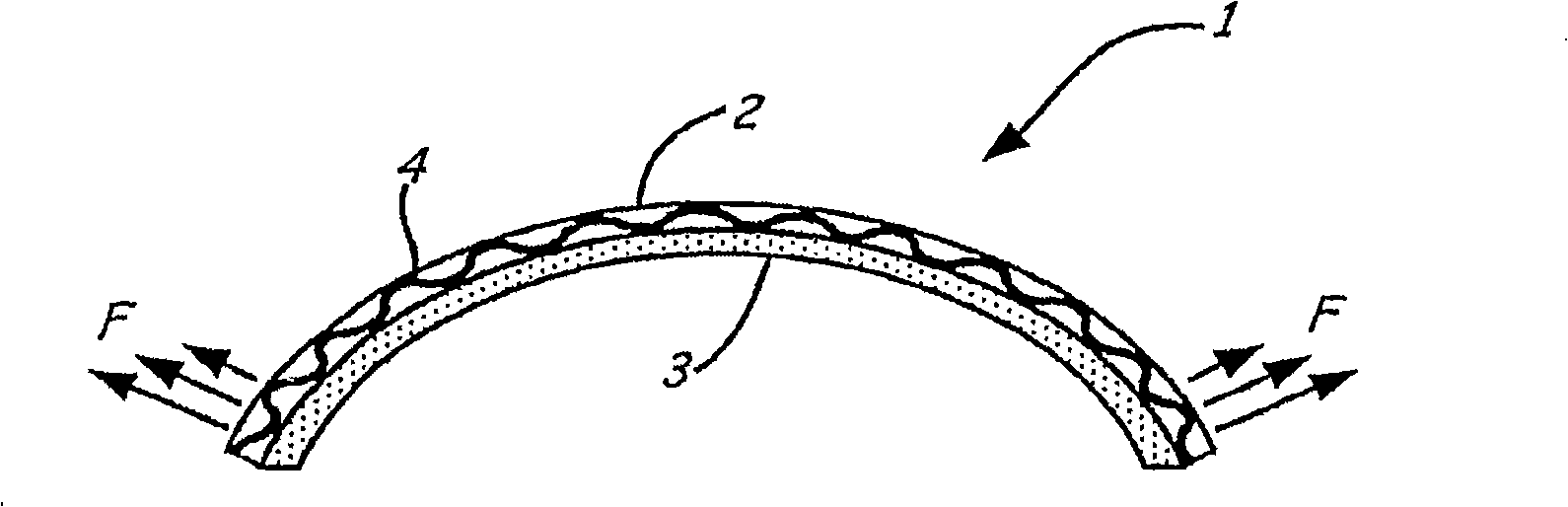

[0017] The present invention comprises two parts forming a nasal dilator strip 1 as shown in FIG. 1 . The spring force layer 2 has a minimum spring force in its latent state, usually a flat state as shown in FIG. 1 . The skin contact layer 3 provides a substrate for adhesion to the nose and is likely to be a hydrocolloid or similar material. As shown in Figure 3, an optional fiber or wire mesh frame 4 can be incorporated into the spring force layer 2 to provide a grid that can shrink and stiffen.

[0018] While the embodiments described herein describe components in layered form, other configurations, such as embedded components, are also within the scope of the invention.

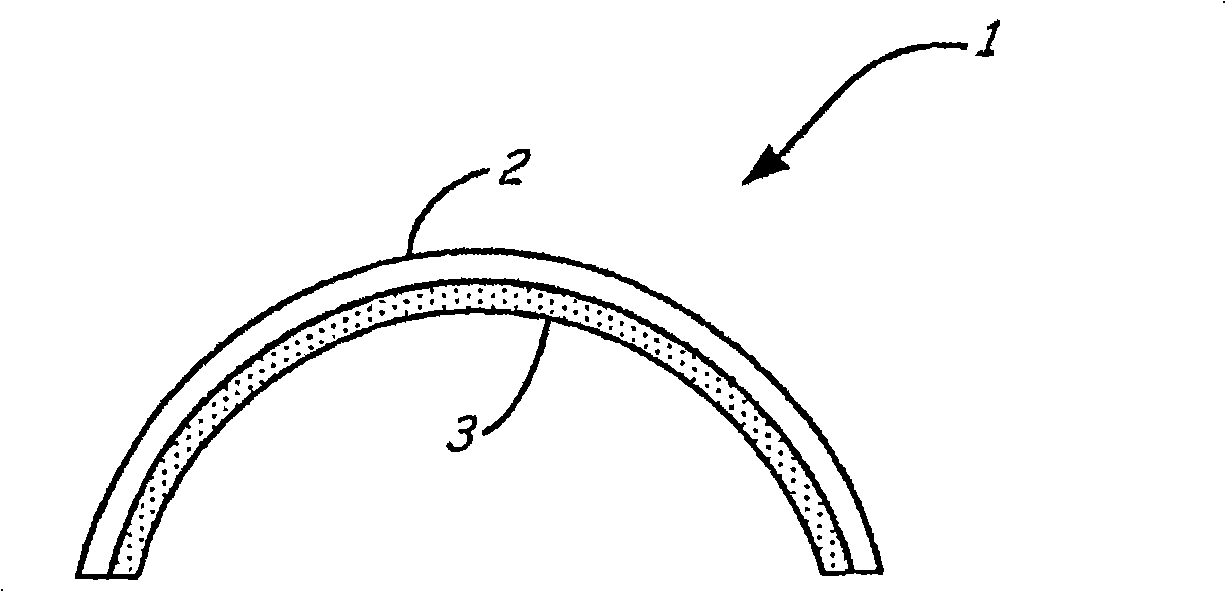

[0019] The nasal dilator strip 1 is attached to the nose by bending the strip 1 to conform to the outer surface of the nose, as shown in FIG. 2 . When a certain activation process is performed, the spring force layer 2 contracts, thereby obtaining an outward spring force F sufficient to be used as a nasa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com