Pneumatic tire and method for manufacturing the same

A technology for pneumatic tires and sidewalls, applied in the field of manufacturing pneumatic tires, can solve problems such as tire surface deformation and internal tire structural defects, and achieve the effect of avoiding air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

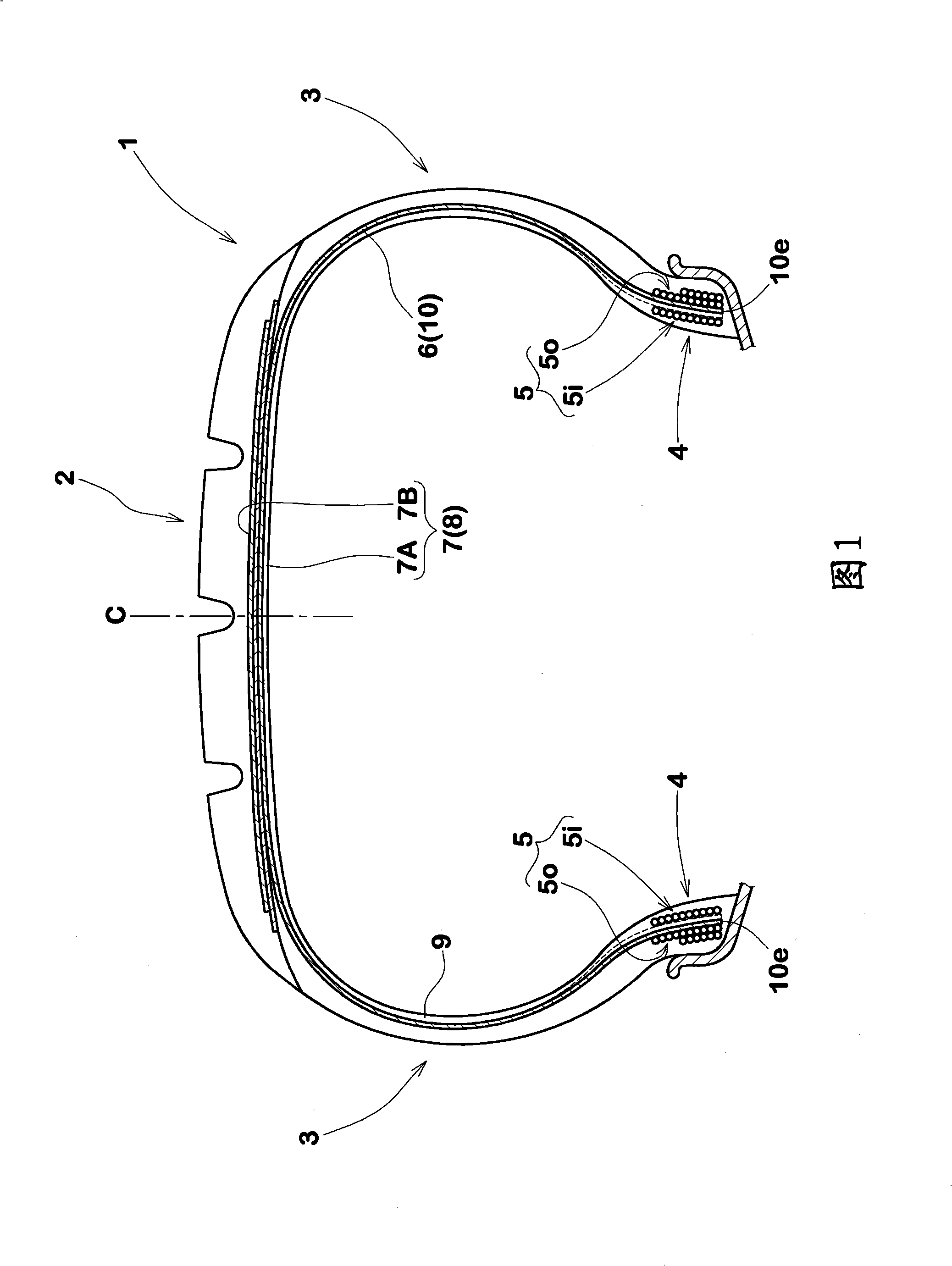

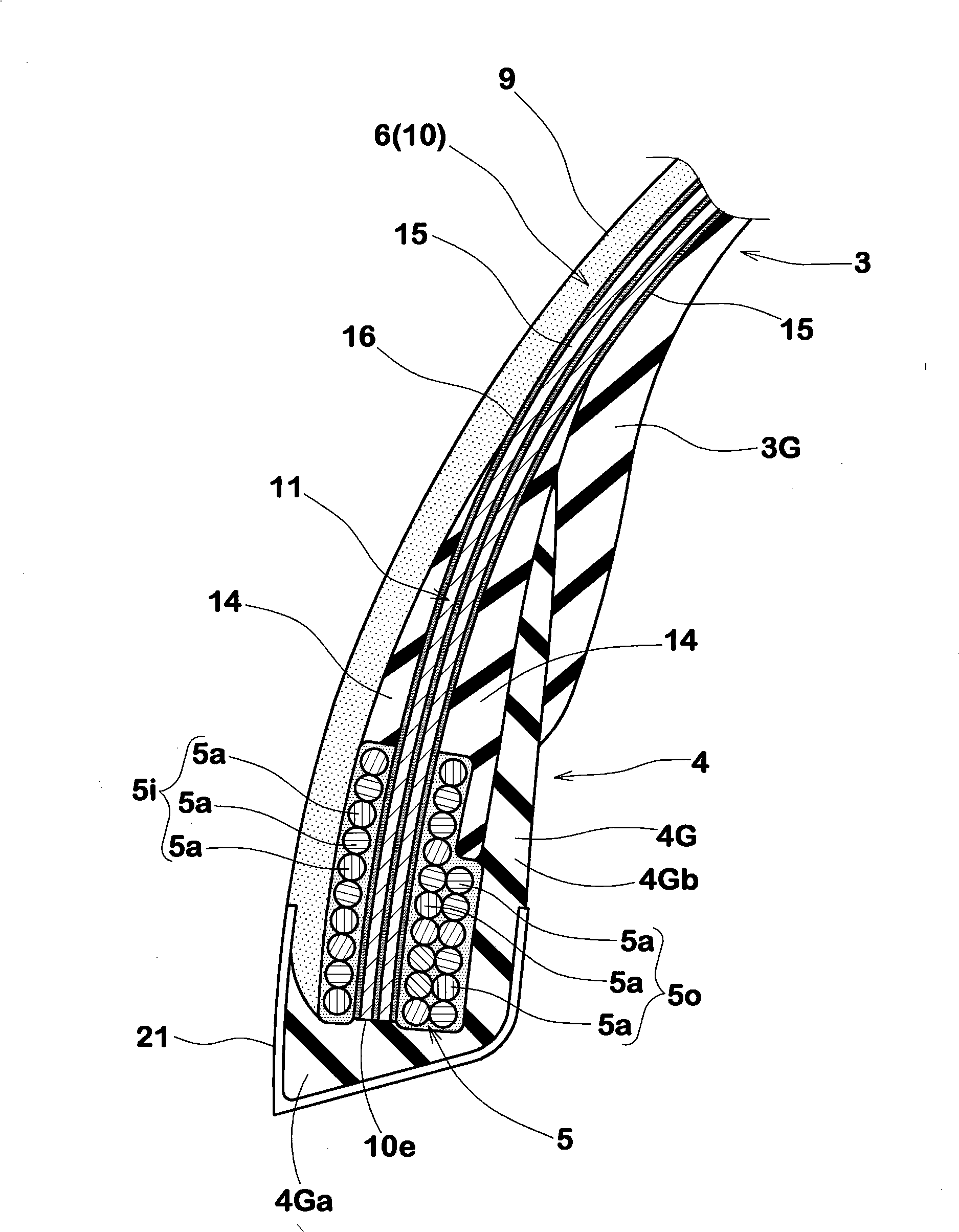

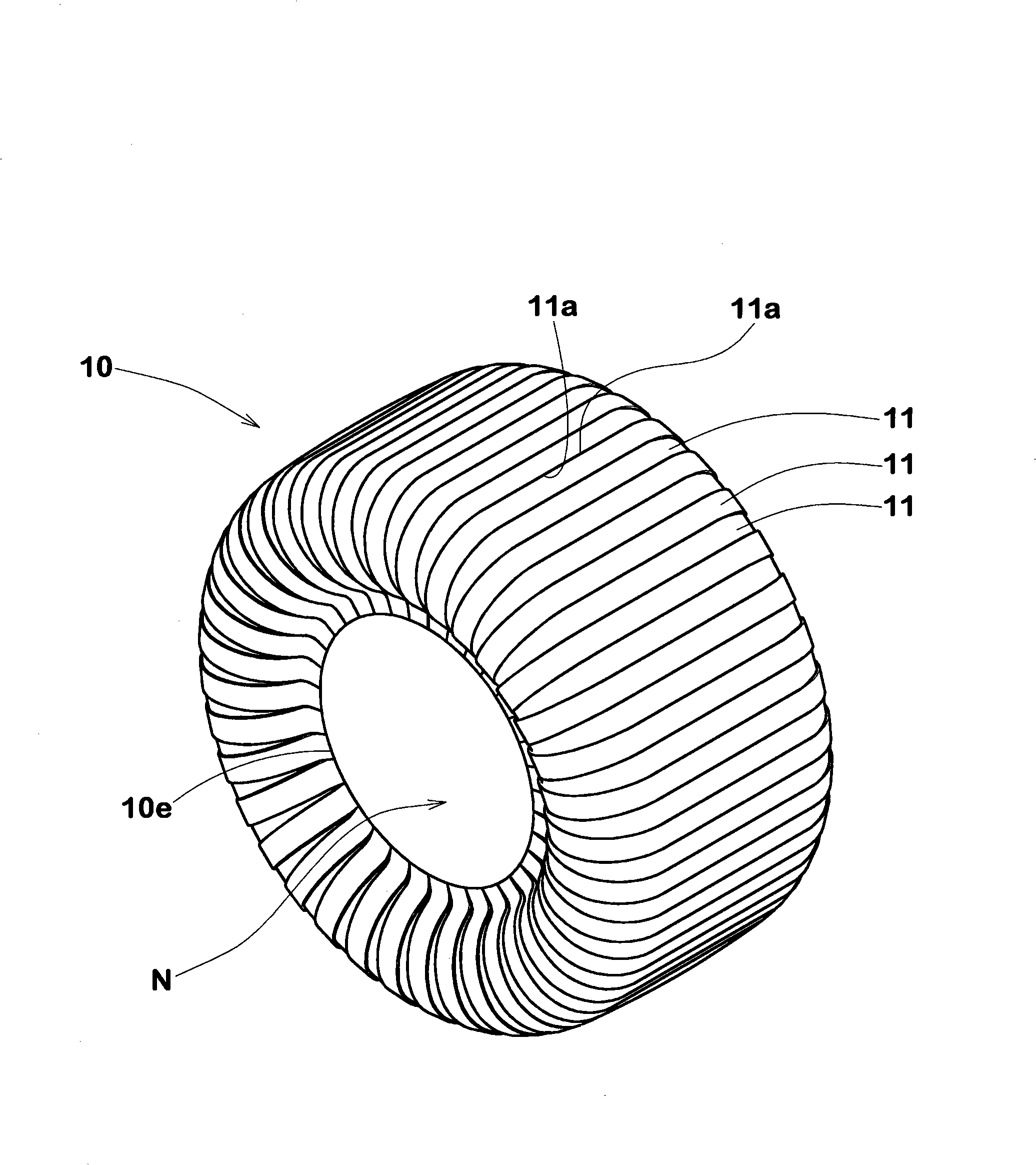

[0025] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0026] According to the present invention, as shown in FIG. 1 , a pneumatic tire 1 includes a tread portion 2, a pair of sidewall portions 3, a pair of bead portions 4, a carcass 6 extending between the bead portions 4, and a tread reinforcement. Belt 8, Tread Reinforcement The belt 8 is provided radially outward of the carcass in the tread portion.

[0027] In the ensuing description, unless otherwise indicated, various dimensions, positions, etc. refer to the dimensions, positions, etc. of the tire under its normal inflated, unloaded condition.

[0028] The normal inflation, no load condition has the tire mounted on a standard rim and inflated to standard pressure, but no tire load is applied. Standard rims are rims for tires that are officially recognized by standards organizations, namely JATMA (Japan and Asia), T&RA (North America), ETRTO (Europe), S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com