Anti-swing mechanism of container gantry crane sling

A gantry crane and container technology, applied in the field of cranes, can solve the problems of inability to achieve anti-swing effect, difficult to form motion damping, difficult maintenance and use, etc., and achieve the effects of easy adjustment and consistency, improved operation efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

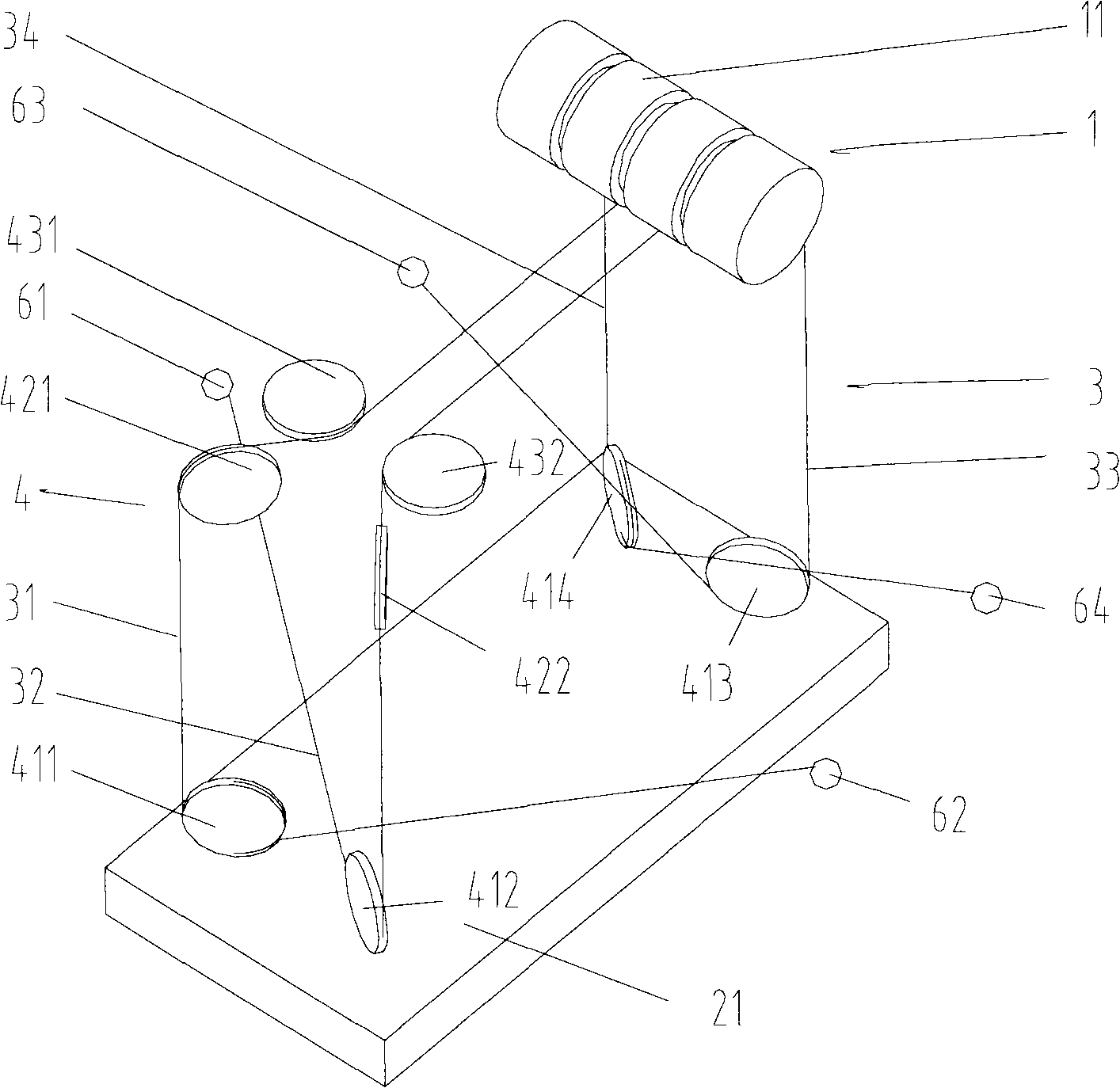

[0026] see figure 2 , which is a schematic structural diagram of the first embodiment of the present invention. It includes: a drum set 1, a spreader upper frame 21, a pulley block 4, and a wire rope set 3 wound on the drum set 1 and the pulley block 4.

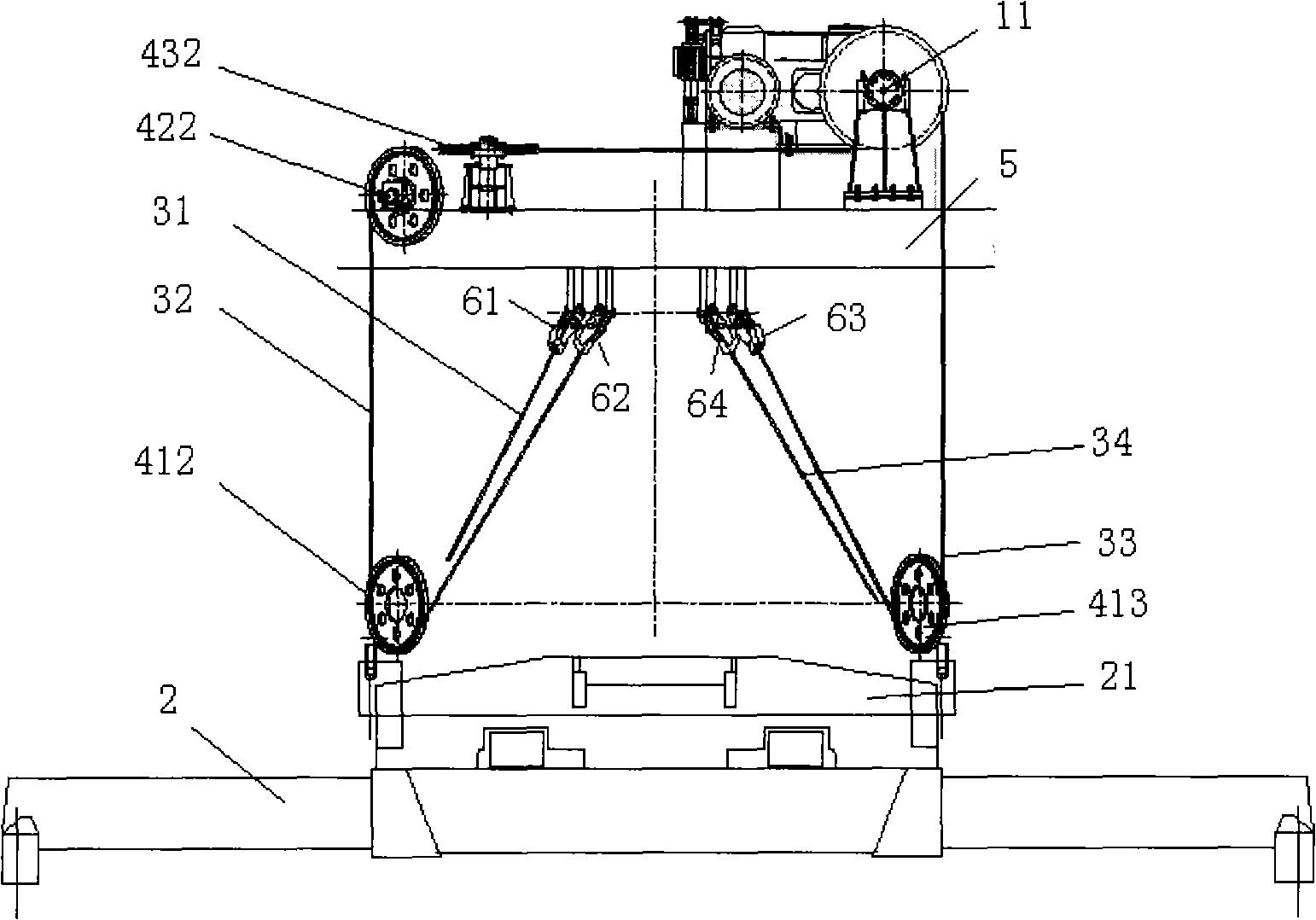

[0027] See also image 3 , Figure 4 ,in: image 3 is the front view of the first embodiment of the present invention; Figure 4 It is a left view of the first embodiment of the present invention, in which a brake 7 and a speed reducer 8 are marked, which can brake or decelerate the trolley.

[0028] The reel set 1, including the reel 11, is installed on one end of the trolley frame 5, and its central axis is parallel to the moving direction of the trolley.

[0029] The spreader upper frame 21 can be fixed above the spreader 2, and the movement conditions between the two are the same. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com