Transmission with a separate breather element

A technology of transmission and components, applied in the direction of components with teeth, transmission parts, belts/chains/gears, etc., can solve problems such as increasing the installation cost of transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

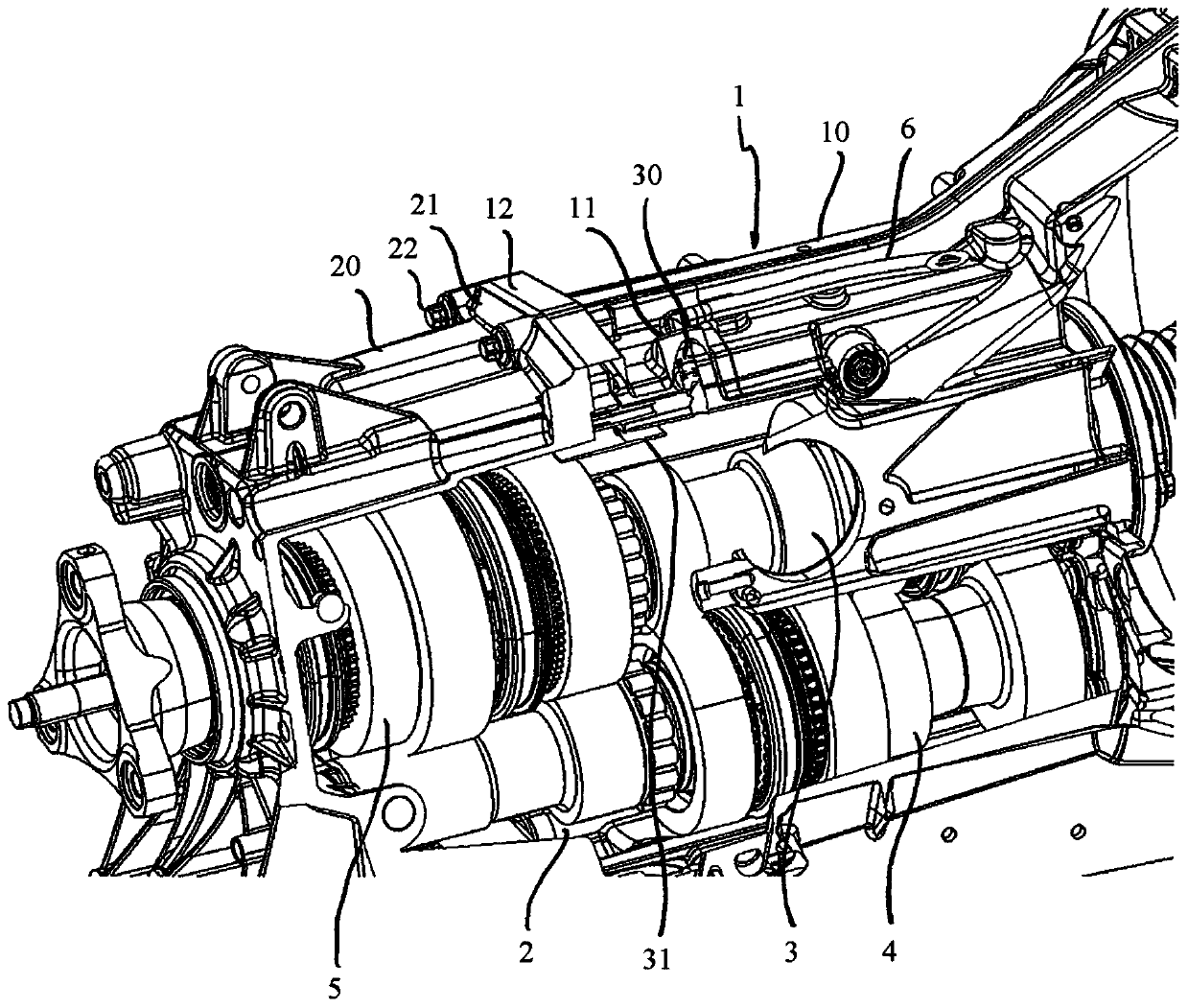

[0024] figure 1 A perspective sectional view of a transmission for an automobile.

[0025] The transmission has a housing 1 comprising a first housing part 10 and a second housing part 20 . The housing 1 encloses an interior 2 of the transmission, in which an input shaft 3 , a countershaft 4 and an output shaft 5 are rotatably mounted. The input shaft 3 is arranged coaxially with the output shaft 5, so figure 1 The transmission shown is an inline transmission.

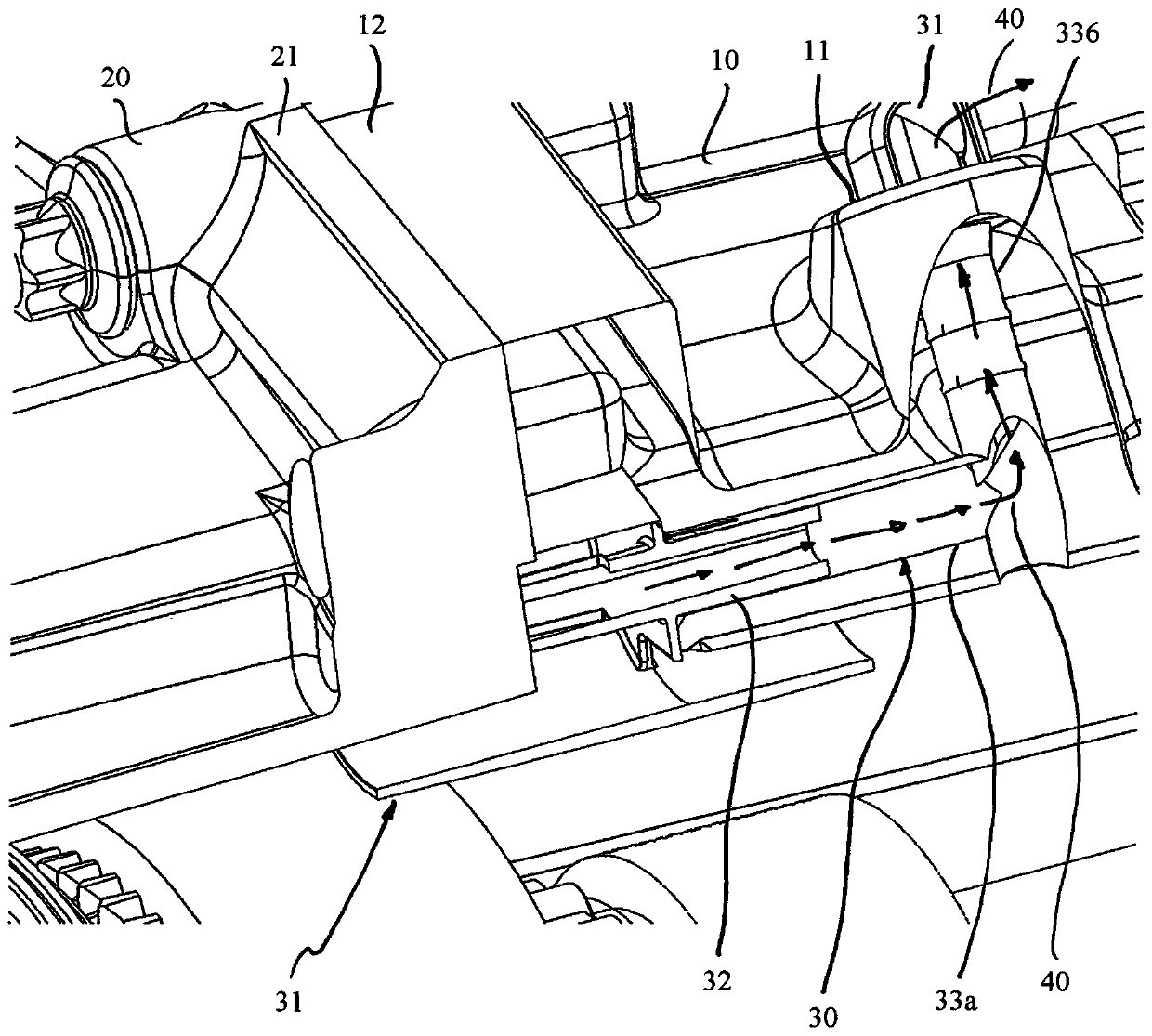

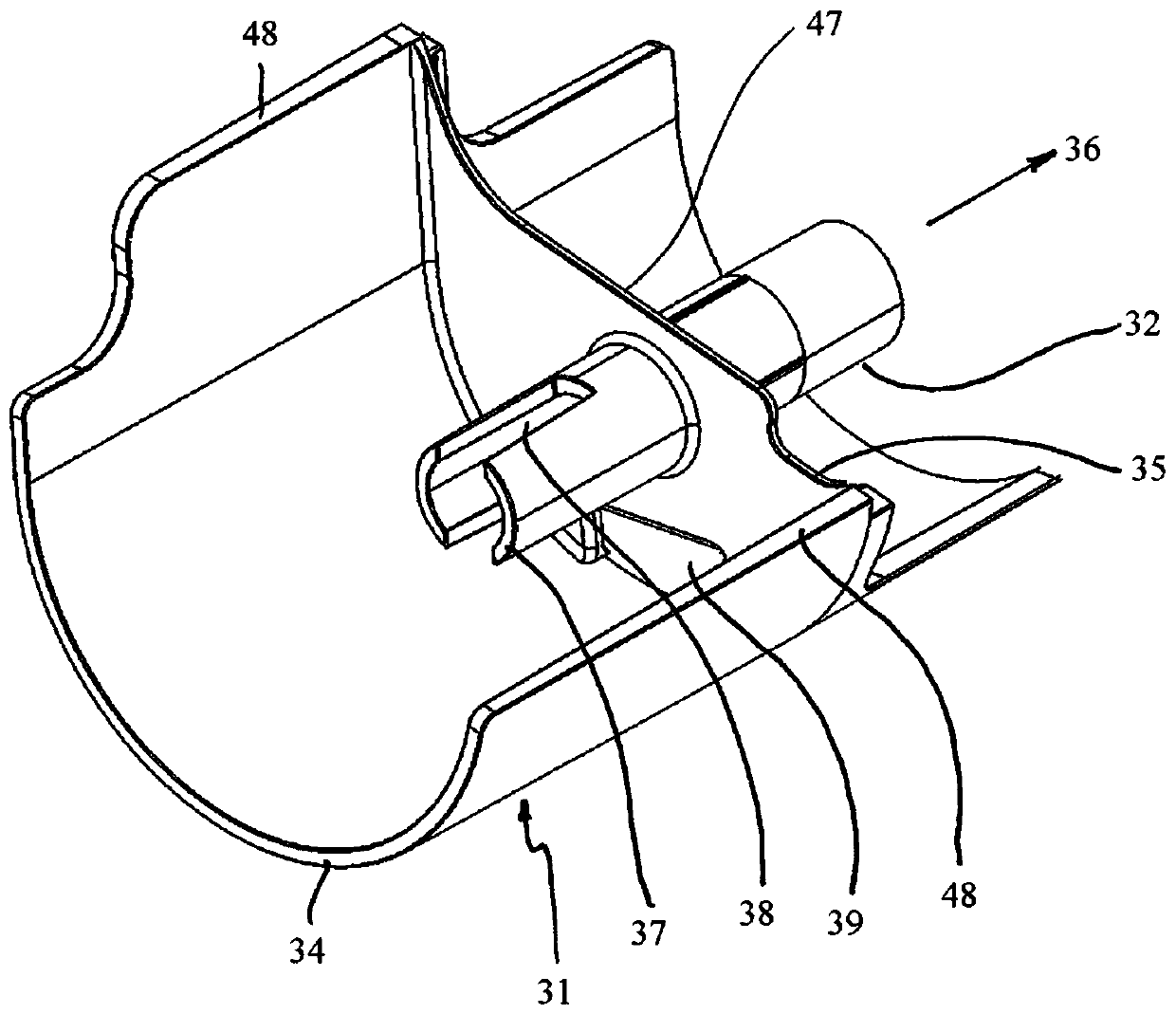

[0026] In the interior 2 there is (transmission) oil, which is centrifugally separated by the rotation of the shafts 3 , 4 , 5 in the interior 2 and the gears arranged thereon. If an increase in temperature occurs in the interior 2 of the transmission, the air in the cavity 2 expands, causing a pressure increase in the transmission. In order to suppress this pressurization, the transmission has an exhaust duct 30 which is formed in the second housing part 20 . figure 1 The exhaust hose 6 can be seen in the figure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com