Under-actuated three-arm non-cooperative target docking capture apparatus

A non-cooperative target and capture device technology, applied in the field of docking capture devices, can solve the problems of extremely high motion control accuracy, target satellite flying away from the docking position, satellite nozzle collision, etc., to achieve wide capture envelope range and reliable control , The effect of high docking reliability

Inactive Publication Date: 2010-12-01

HARBIN INST OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention solves the problem that the existing non-cooperative target docking mechanism is prone to collide with the satellite nozzle during docking, causing the target satellite to fly away from the docking position, resulting in poor docking reliability, and the existing non-cooperative target docking mechanism controls the accuracy of its own motion extremely demanding problem, and thus provides an underactuated three-arm non-cooperative target docking capture device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

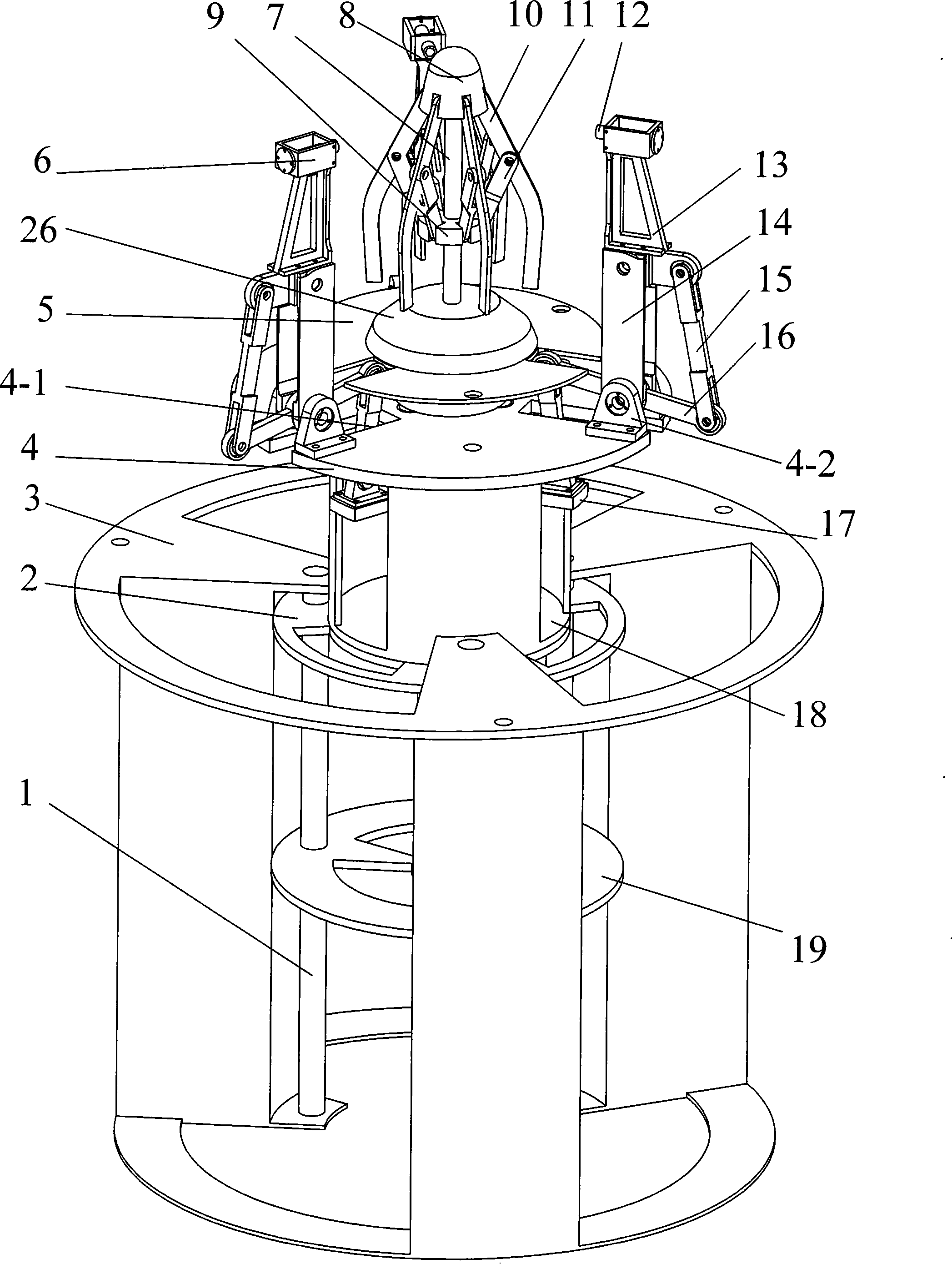

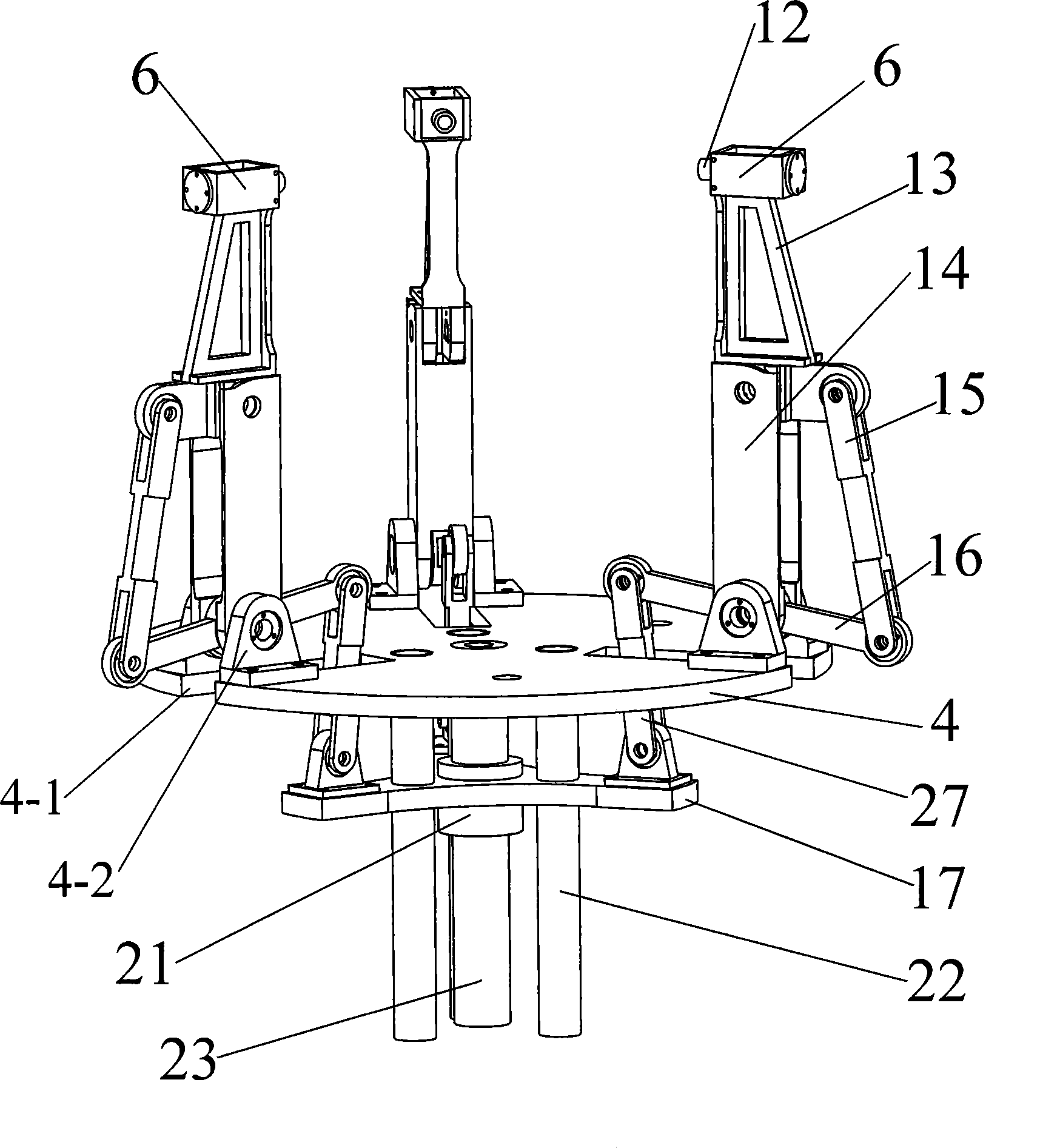

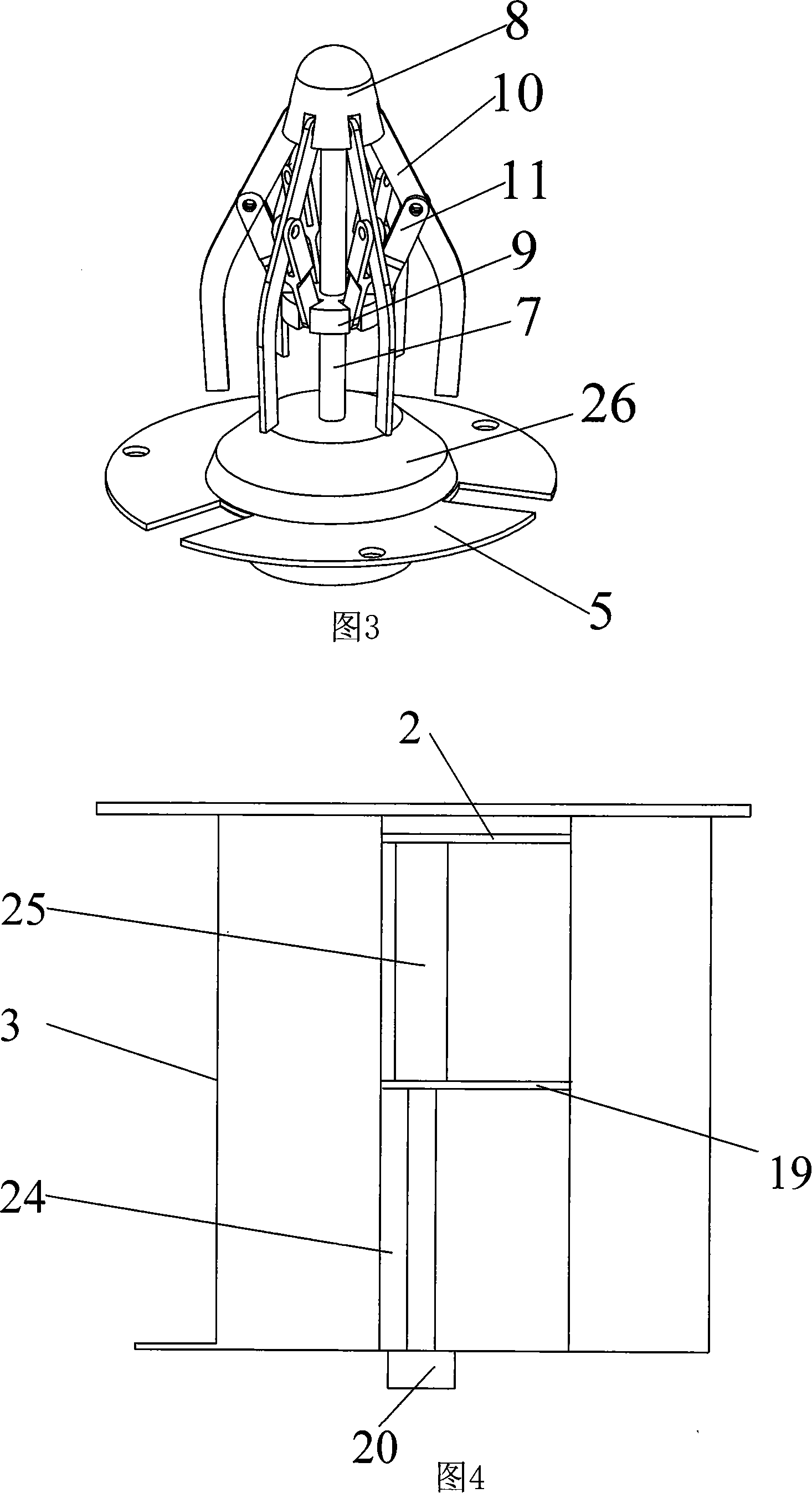

The invention provides an under-actuated three-arm type non-cooperative target docking-capturing device, relating to a docking-capturing device. The invention solves the problem that: the prior non-cooperative target docking mechanism is easy to collide with satellite spray pipes in a docking process, thereby causing poor docking reliability. An under-actuated manipulator motor (18) is arranged on an upper end face of a lead screw nut plate (2) on a lifting mechanism; an output shaft of the under-actuated manipulator motor (18) is connected with a ball lead screw (23); the ball lead screw (23) is sleeved with a nut (21); a manipulator driving plate (17) is fixed on the nut (21); three manipulators are evenly arranged on a manipulator mounting platform (4); the other ends of three first coupling-connecting rods are respectively in rotary connection with the manipulator driving plate (17); and an umbrella-shaped buffer mechanism is positioned above and flexibly connected with the manipulator mounting platform (4). The docking-capturing device has the advantages of high docking reliability, wide capture enveloping range, few drive elements, simple control, rapid capture, etc.

Description

Under-driven three-arm type non-cooperative target docking capture device Technical field The invention relates to a docking capture device, in particular to a docking capture device for space non-cooperative target satellites. Background technique The non-cooperative target docking technology is different from the previous docking technology in that its docking target is a satellite without a docking interface. Therefore, the apogee recoil engine (AKM) nozzle of the satellite is generally selected as the docking interface. The existing non-cooperative target docking mechanism with the apogee recoil engine as the docking interface is shown in FIG. 5, and includes a tension pin 116, a docking rod 117, a motor 118, a sensor 119, and a docking mechanism housing 120. The working principle of the docking mechanism is: the tension pin 116 installed on the docking rod 117 is driven by the motor 118 to move closer to the AKM nozzle throat. When the sensor 119 detects the insertion of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B64G1/64

Inventor 张广玉柏合民丰飞李隆球陈志刚王晓雪

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com