Cableless docking device and docking method for aircraft cabin

A docking device and a technology for an aircraft, applied in the field of aircraft, can solve problems such as unfavorable aircraft cabin docking, unfavorable aircraft maintenance, low docking accuracy, etc., and achieve the effects of improving docking efficiency, simple docking method, and high docking reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

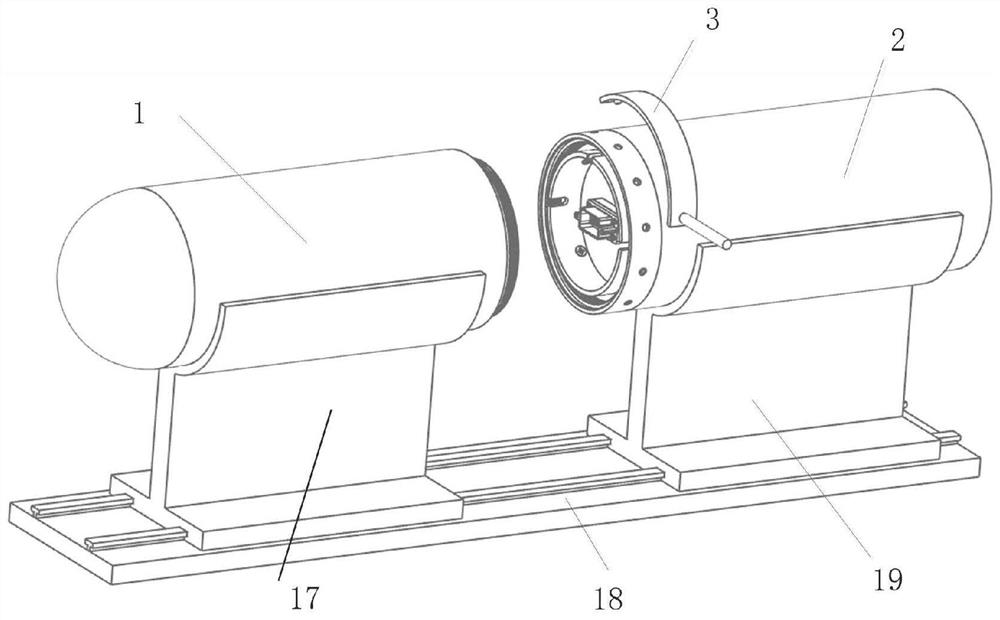

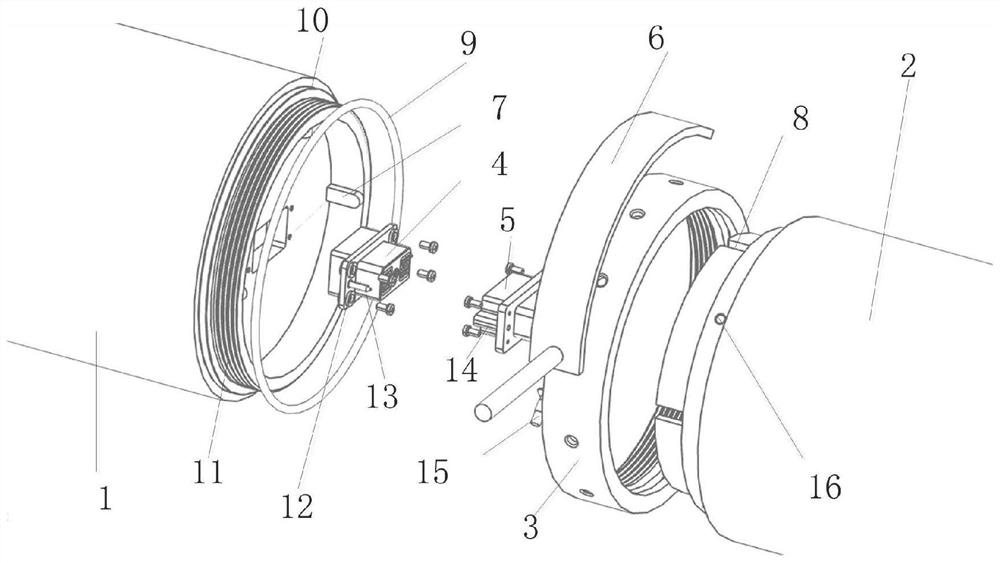

[0039] A specific embodiment of the present invention discloses a cableless docking device for cabin sections of an aircraft, comprising: a first cabin section 1 , a second cabin section 2 , a screw sleeve 3 , a first connector 4 and a second connector 5 .

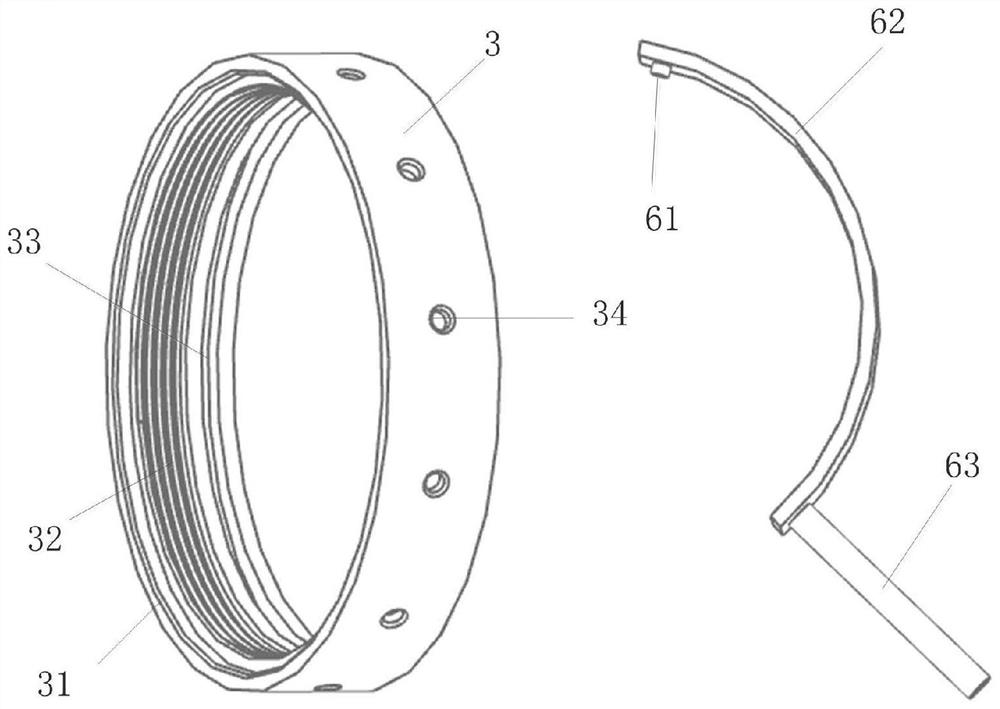

[0040] The screw sleeve 3 is a ring structure, and the inner surface is provided with a screw sleeve internal thread 32 , the screw sleeve 3 is installed on the second cabin section 2 and can rotate relative to the second cabin section 2 . The connecting end of the first compartment 1 is provided with the external thread 11 of the compartment, and the screw sleeve 3 is made to cooperate with the internal thread 32 of the nut and the external thread 11 of the compartment, so as to realize the structural fixation of the first compartment 1 and the second compartment 2, That is, the mechanical connection between the first compartment 1 and the second compartment 2 is realized.

[0041] Further, as figure 1 As shown, the firs...

Embodiment 2

[0067] This embodiment provides a cable-free docking process for aircraft cabins, including the alignment between cabins, guiding, positioning, locking, and synchronous alignment with anti-loosening and connectors, taking into account the joint length of cabins and connectors The docking length ensures that when the cabin is locked in place, the connector is also docked in place at the same time.

[0068] A cableless docking method for an aircraft cabin, using the cableless docking device for an aircraft cabin in Embodiment 1, and the specific steps include:

[0069] Step 1: Install the first cabin section 1 and the second cabin section 2 on the first cabin section bracket 17 and the second cabin section bracket 19 respectively; install the screw sleeve 3 on the second cabin section 2, and the screw sleeve 3 Can rotate relative to the second compartment.

[0070] Specifically, the screw sleeve 3 is set on the step surface of the connecting end of the second cabin section 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com