Novel bulk cement current tank avoiding hanging and hanging discharge

A bulk cement, hoisting-free technology, used in packaging, transportation and packaging, containers, etc., can solve the problems of high hoisting, hoisting, unloading and transportation costs, inconvenience, etc., to save transportation costs, reduce transportation space, and increase the number of transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

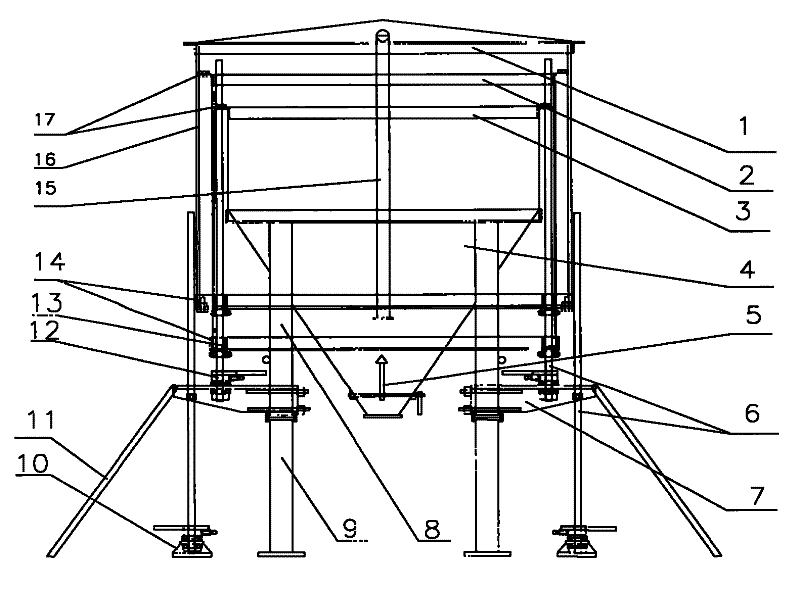

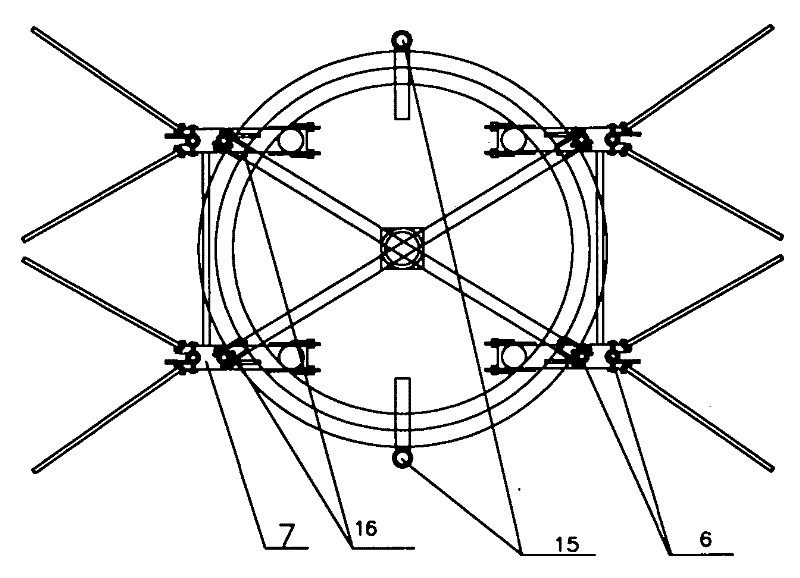

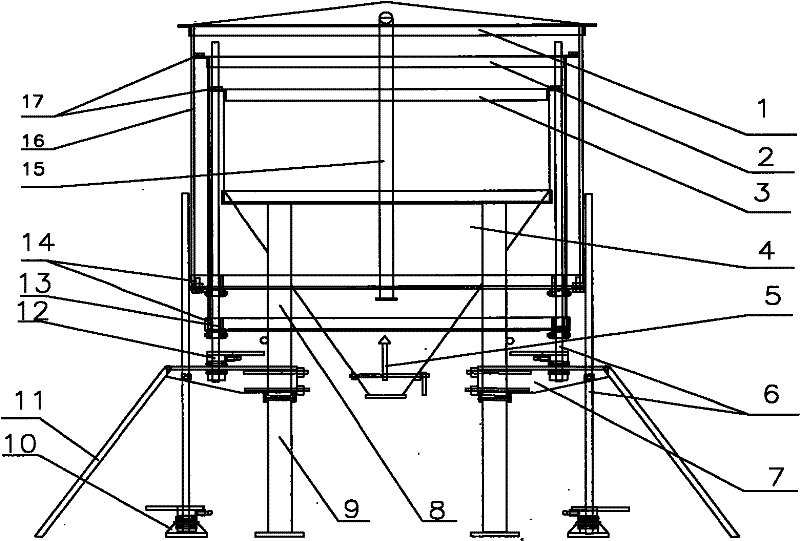

[0015] The present invention is further explained in conjunction with the accompanying drawings. The bulk cement flow tank without hoisting is mainly composed of four parts: a socket tank body, a lower cone, a foot, and a screw lifting device; the socket tank body is composed of an upper tank body 1, The middle tank body 2 and the lower tank body 3 are socketed; the upper end of the upper tank body 1 is welded to the top cover of the tank body, the upper end of the top cover is welded to the feed pipe and exhaust pipe 15, and the lower end flange of the upper tank body 1 passes through the tank body flange The tank body flange nut 17 welded by the bolt 14 and the middle tank body 2 upper end flange is fixed, and the tank body flange nut 17 welded by the tank body flange bolt 14 and the lower tank body 3 upper end flange by the middle tank body 2 lower end flange. The cap 17 is fixed, the lower end of the lower tank body 3 is welded to the upper end of the lower cone 4; The leg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com