Ballast circuit for high-intensity discharging lamp

A high-intensity discharge lamp and ballast technology, applied in the field of control, can solve the problems of acoustic resonance, high ignition voltage, high cost, etc., and achieve the effect of avoiding acoustic resonance, mature and reliable, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

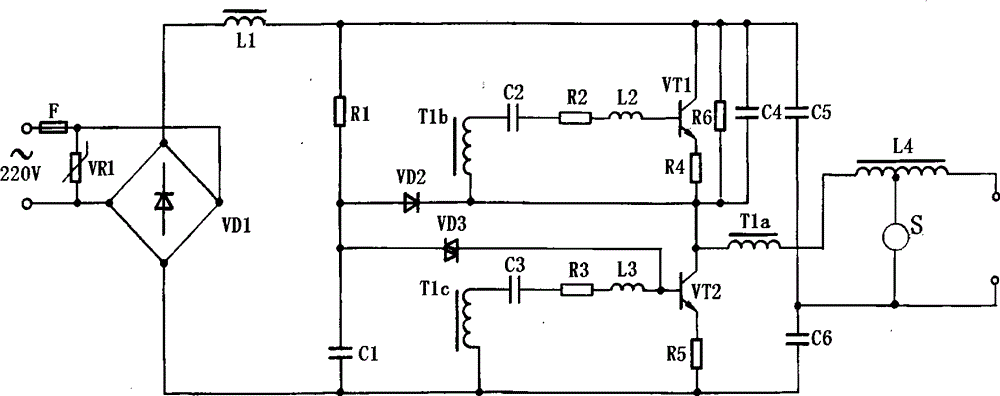

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] attached figure 1 A DC-AC inverter ballast circuit with low-cost bipolar transistors (BJT) is given to avoid the acoustic resonance region of the high-intensity discharge lamp with pre-selected frequency. In the graphic symbols, "V" is marked before the components related to the power supply.

[0013] The high-intensity discharge lamp ballast circuit includes an AC-DC conversion module and a DC-AC inverter circuit module.

[0014] AC-DC conversion module includes bridge rectifier VD1, varistor VR1, filter inductor L1, first filter capacitor C5, second filter capacitor C6, fuse F; one input end of bridge rectifier VD1 and one end of varistor VR1 It is connected to one end of the single-phase AC power supply, the other input end of the bridge rectifier VD1 is connected to the other end of the varistor VR1 and one end of the fuse F, and the other end of the fuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com