Methods for optimizing efficiency and durability of rotary drag bits and rotary drag bits designed for optimal efficiency and durability

A drill bit and drilling technology, applied in the field of rotary traction drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Several drill bits were evaluated according to the teachings of the present invention.

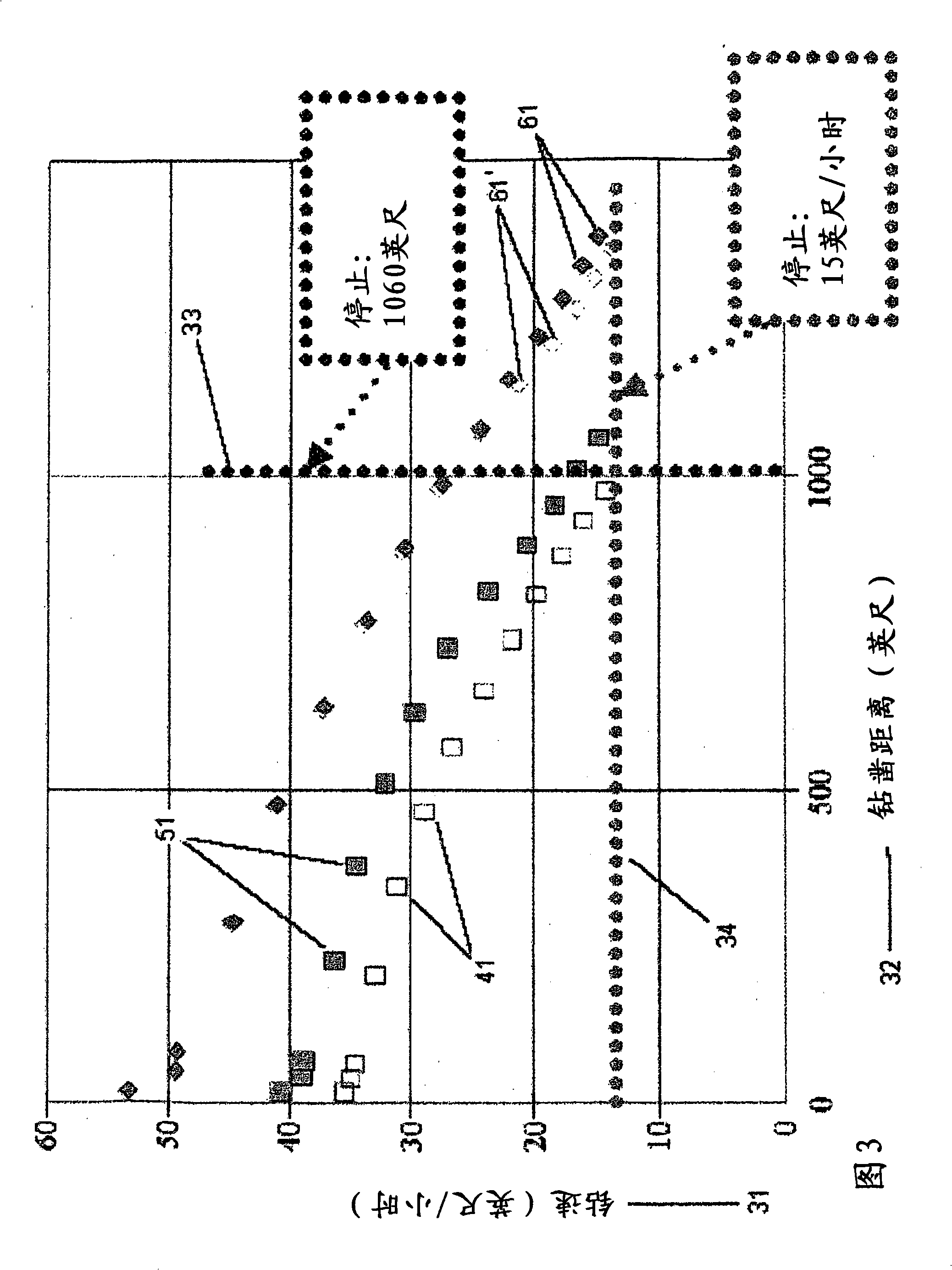

[0043] Figure 3 is an aggregated block of data collected in the field with existing bit designs and data from computer simulations of new bit designs. Existing drill bits drill into a given formation and collect data, including rate of penetration (ROP) and distance drilled. The Y-axis 31 represents the average rate of penetration (ROP) in feet per hour, while the X-axis 32 represents the distance drilled into the formation in feet. The X-axis 32 starts at 0 feet drill distance, which indicates that the drill bit has not drilled the formation, ie, the drill bit is new. The distance drilled by the bit increases linearly to the right along the X-axis 32 . Two standards are imposed on the graph, and the working performance of the drill bit is compared with this. The vertical dashed line 33 represents a total drilled distance of 1060 feet (323 meters), the distance that has been dril...

example 2

[0057] In another example of the method, Figures 4 and 8 provide representative examples showing axial views and contours of the cutting elements of two drill bits for which a computer model was built, and Figure 5 shows a third drill bit outline drawing. Figures 4 and 5 are as described above. Figure 8 is a diagrammatic representation of a Hughes Christensen drill bit model HC511Z. The drill bit 81 has a plurality of cutting elements 82 located on a plurality of cutting edges 83, visible in an axial view of the drill bit, as are a plurality of jets 84. The center of the bit is the cone 85 and the radially outermost of the bit is the gauge distance 86 or radial distance. Adjacent to the axial view of the drill bit 81 is a contour map 87 . The radial and axial positioning of each primary cutting element 82 is shown as it passes through the corresponding plane on the page of FIG. 8 . Two vertical lines 88 and 89 respectively represent the positions of the cutting elements 82...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com