Underrun protector mounting structure of vehicle

An installation structure, anti-drilling technology, applied in the direction of vehicle safety arrangement, vehicle components, transportation and packaging, etc., can solve problems such as weight increase, cost increase, complex shape, etc., and achieve the effect of improving rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

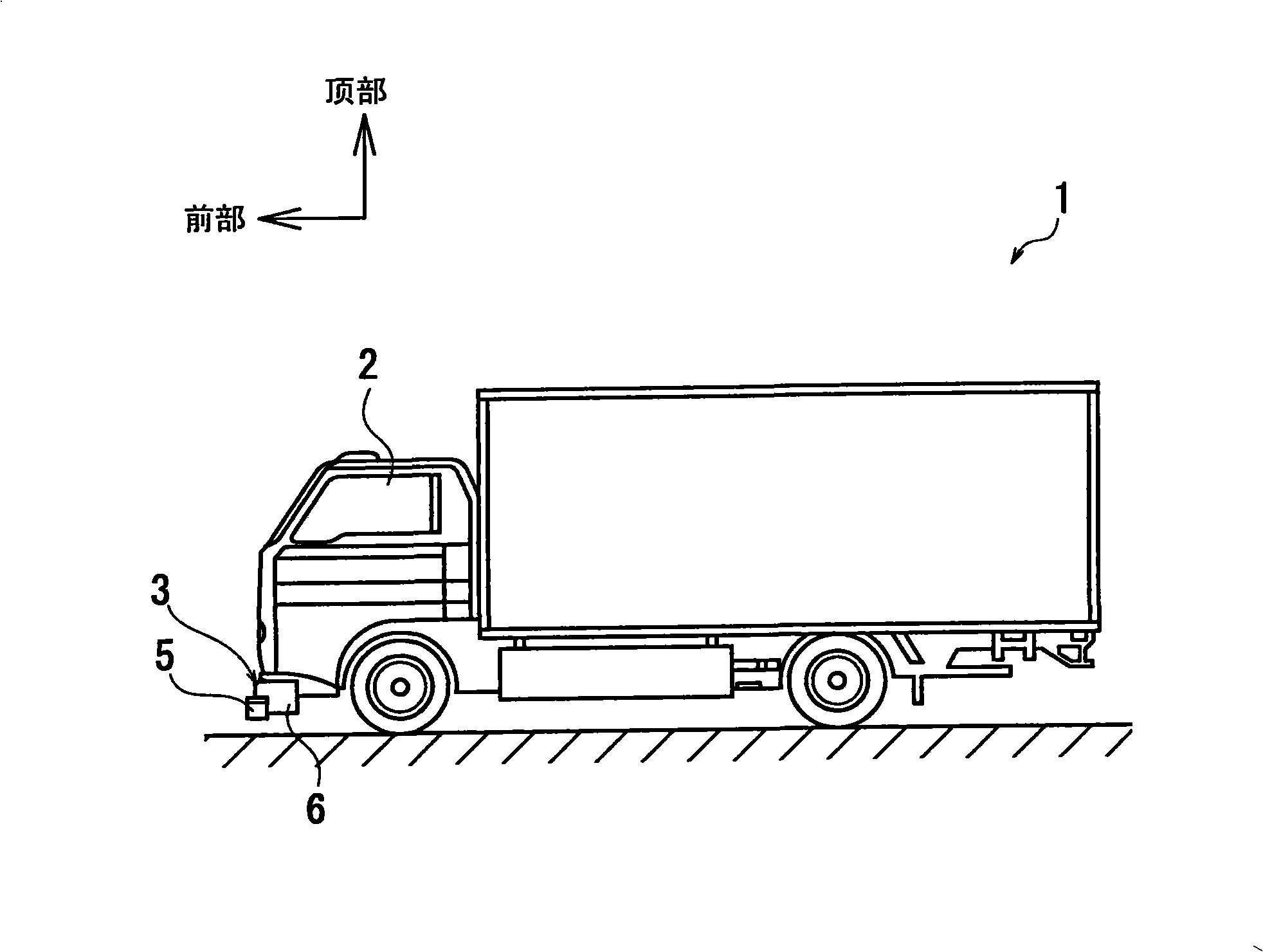

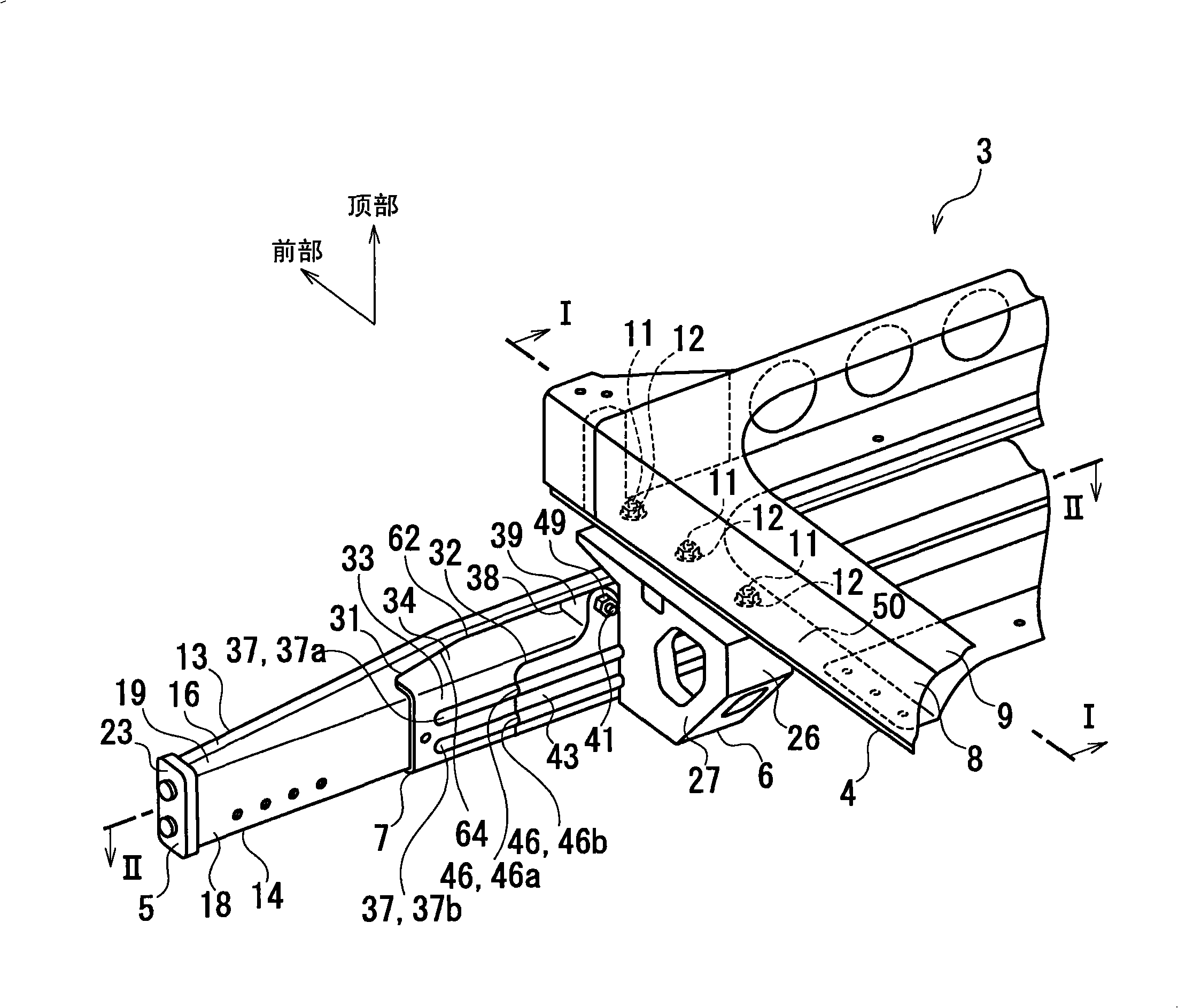

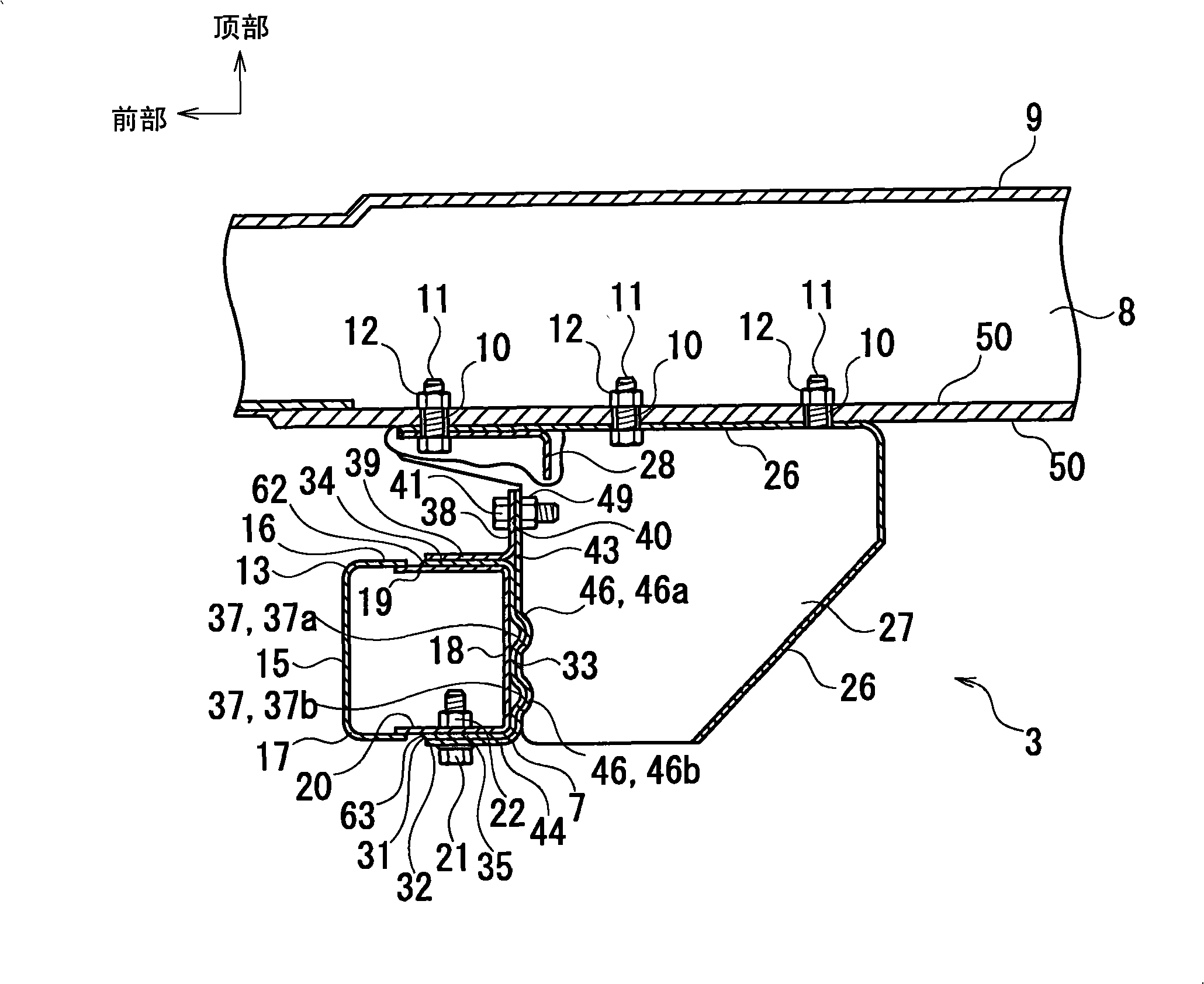

[0060] Referring to the drawings, embodiments of the present invention will be described below. figure 1 is a schematic side view of the cab-over truck according to this embodiment. figure 2 It is an enlarged perspective view of the main part of the underrun protector installation structure. image 3 is along figure 2 A cross-sectional view taken along the line I-I. Figure 4 is along figure 2 A cross-sectional view taken along the line II-II. Figure 5 It is an exploded perspective view of the installation structure of the underrun protection device. Fig. 6 is an exploded perspective view of the installation structure of the underrun protector. Figure 7 is an enlarged cross-sectional view of the main part, showing the state where an impact load acts on the front underrun protector. Figure 8 is a schematic diagram of a front underrun protector modeled as a cantilever beam. Note that "front" in the drawings represents the front of the vehicle, and "top" in the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com