Method for enhancing service life of wind power generator paddle

A technology of wind turbines and blades, which is applied in the control of wind engines, wind engines, wind power generation, etc., and can solve the problems of fiberglass blade fatigue, damage, blade damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

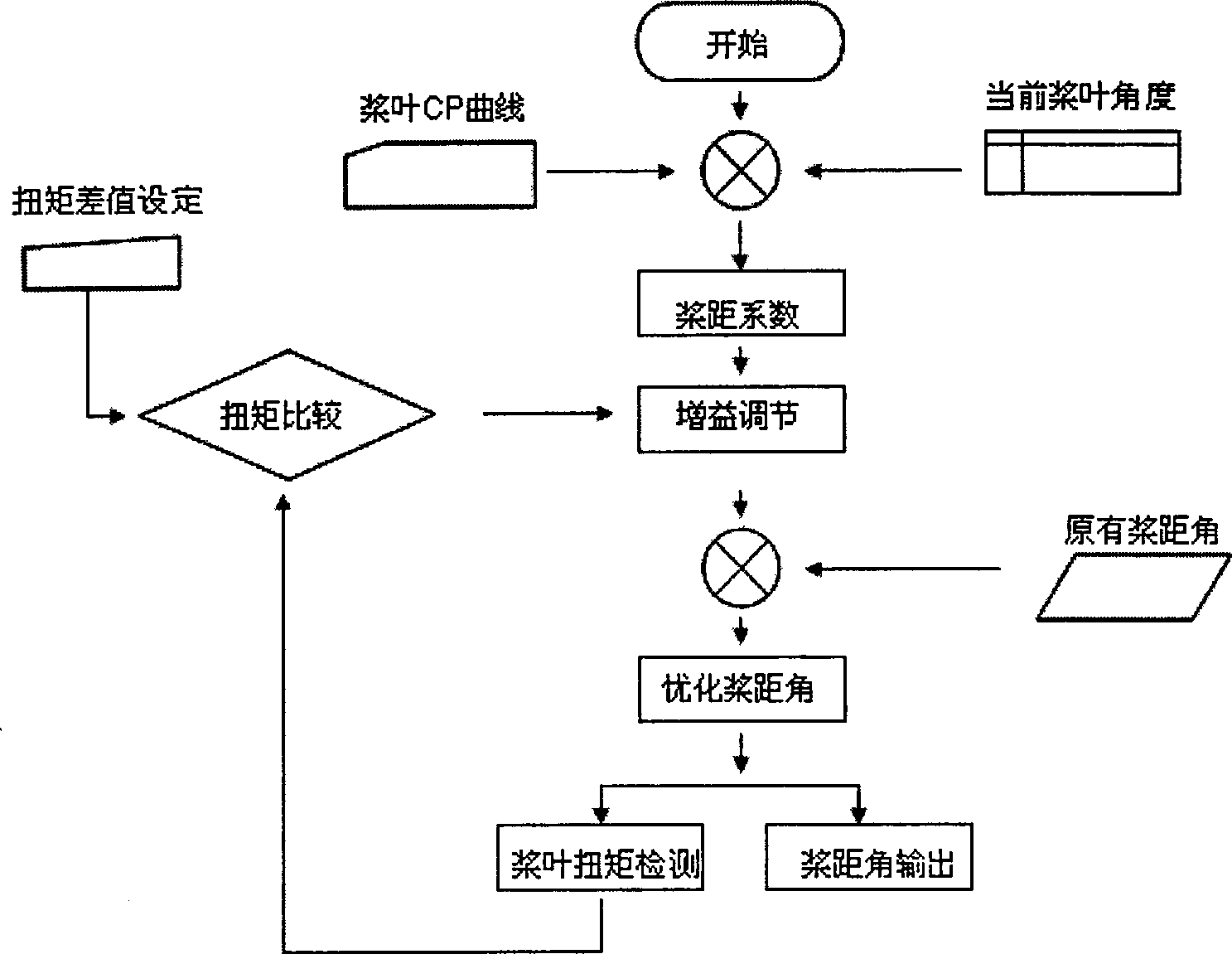

[0021] Embodiment 1: This embodiment is a 1.5MW doubly-fed blade. It calculates the corresponding pitch angle of each blade according to the different positions of each blade and the table value of the blade angle coefficient (the blade angle of the inherent CP curve characteristic of the blade) of the mechanical characteristics of the fan blade (see part of the attached table).

[0022] The method of this embodiment is:

[0023] 1. When the wind speed changes between the cut-in wind speed and the rated wind speed, use variable speed control to track the best power curve to obtain the maximum power.

[0024] 2. When the wind speed changes between the rated wind speed and the cut-out wind speed, adopt variable pitch control to control the stress on the blades by adjusting the blade pitch angle, and keep the rated power of the power generation system unchanged.

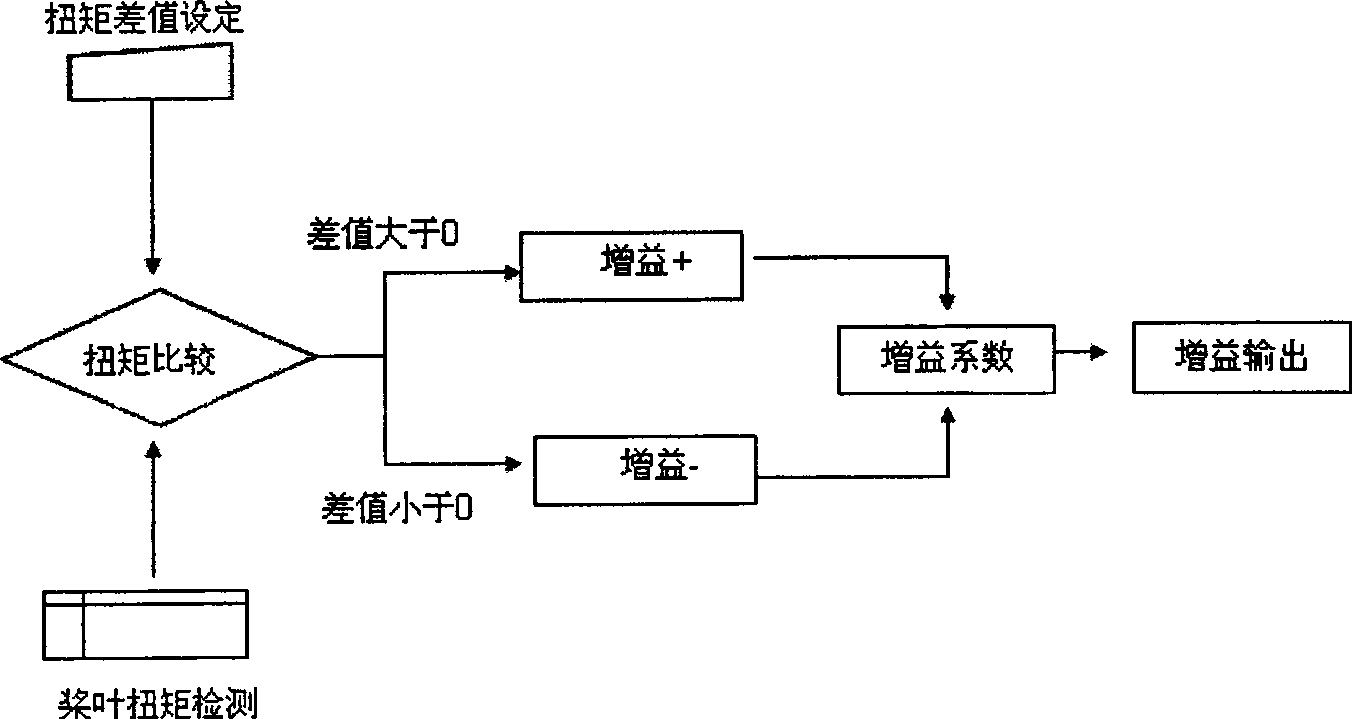

[0025] 3. In the step of pitch control, the following steps are also adopted:

[0026] 1), obtain the pitch angle K...

Embodiment approach 2

[0033] Embodiment 2: This embodiment is a 1.5MW doubly-fed blade. It establishes a real-time calculation model to calculate the pitch angle of each blade, and collects real-time torque values for comparison and correction.

[0034] The method of this embodiment is:

[0035] 1. When the wind speed changes between the cut-in wind speed and the rated wind speed, use variable speed control to track the best power curve to obtain the maximum power.

[0036] 2. When the wind speed changes between the rated wind speed and the cut-out wind speed, adopt variable pitch control to control the stress on the blades by adjusting the blade pitch angle, and keep the rated power of the power generation system unchanged.

[0037] 3. In the step of pitch control, the following steps are also adopted:

[0038] 1), obtain the pitch angle K of blade by traditional pitch control method;

[0039] 2), read the current actual torque of each blade in each blade driver through the bus;

[0040] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com