Non aqueous electrolyte secondary batteries

A non-aqueous electrolyte and secondary battery technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of high manufacturing cost and a lot of time, and achieve the effect of improving current collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

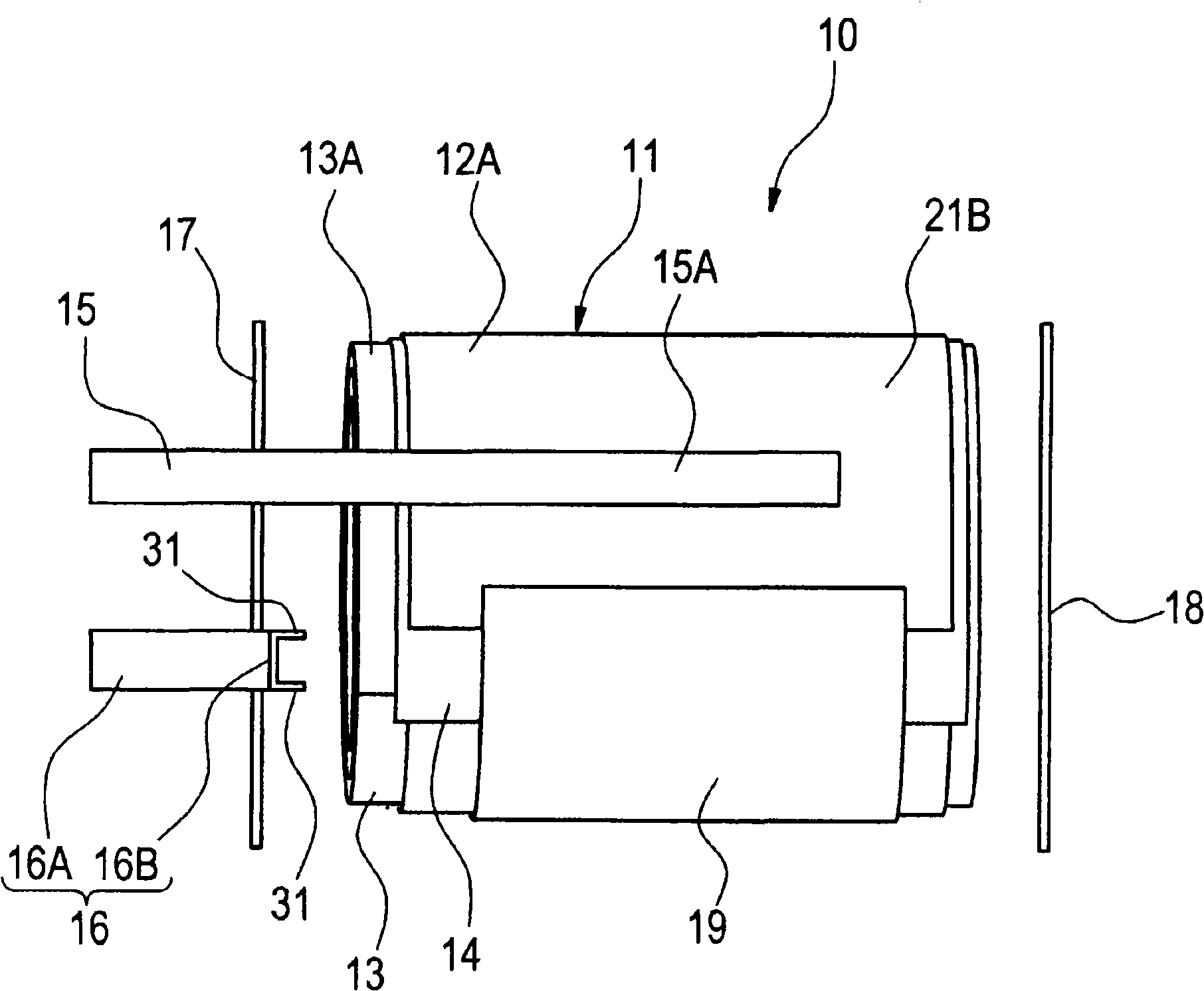

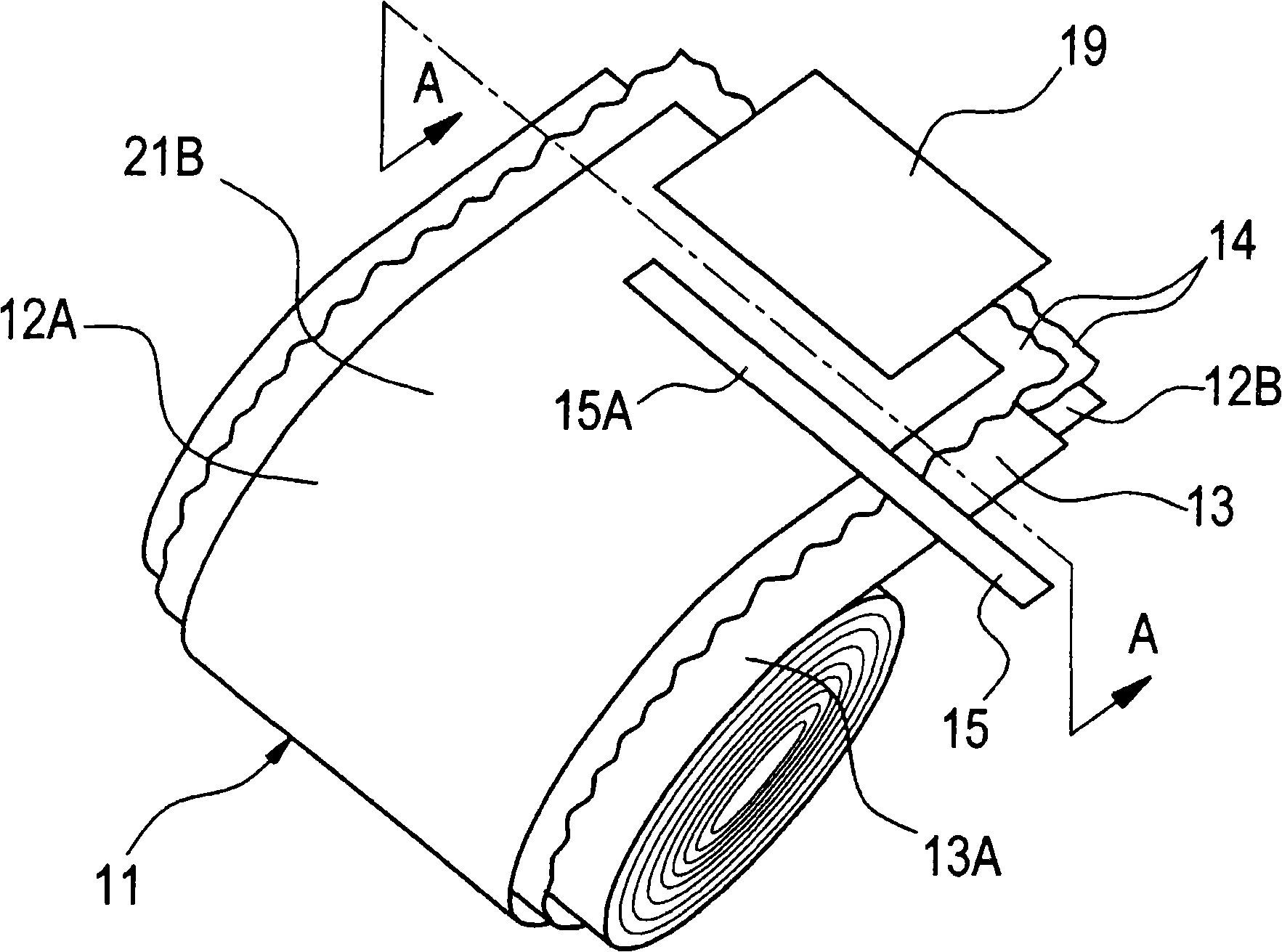

[0037] Such as Figure 1 ~ Figure 2 As shown, the nonaqueous electrolyte secondary battery 10 according to the first embodiment has a battery element 11 in which a first positive electrode 12A, a second positive electrode 12B, and a negative electrode 13 are wound in a stacked state through a separator 14; a positive electrode terminal 15 is connected to positive electrode 12A; negative terminal 16 connected to negative electrode 13; top insulator 17 supporting positive terminal 15 and negative terminal 16 and connected to one end face of battery element 11 ( figure 1 and the bottom insulator 18, and the other end surface of the battery element 11 ( figure 1 Opposite to the right-hand side in ), the battery element 11 is sealed by a cylindrical laminate package (not shown).

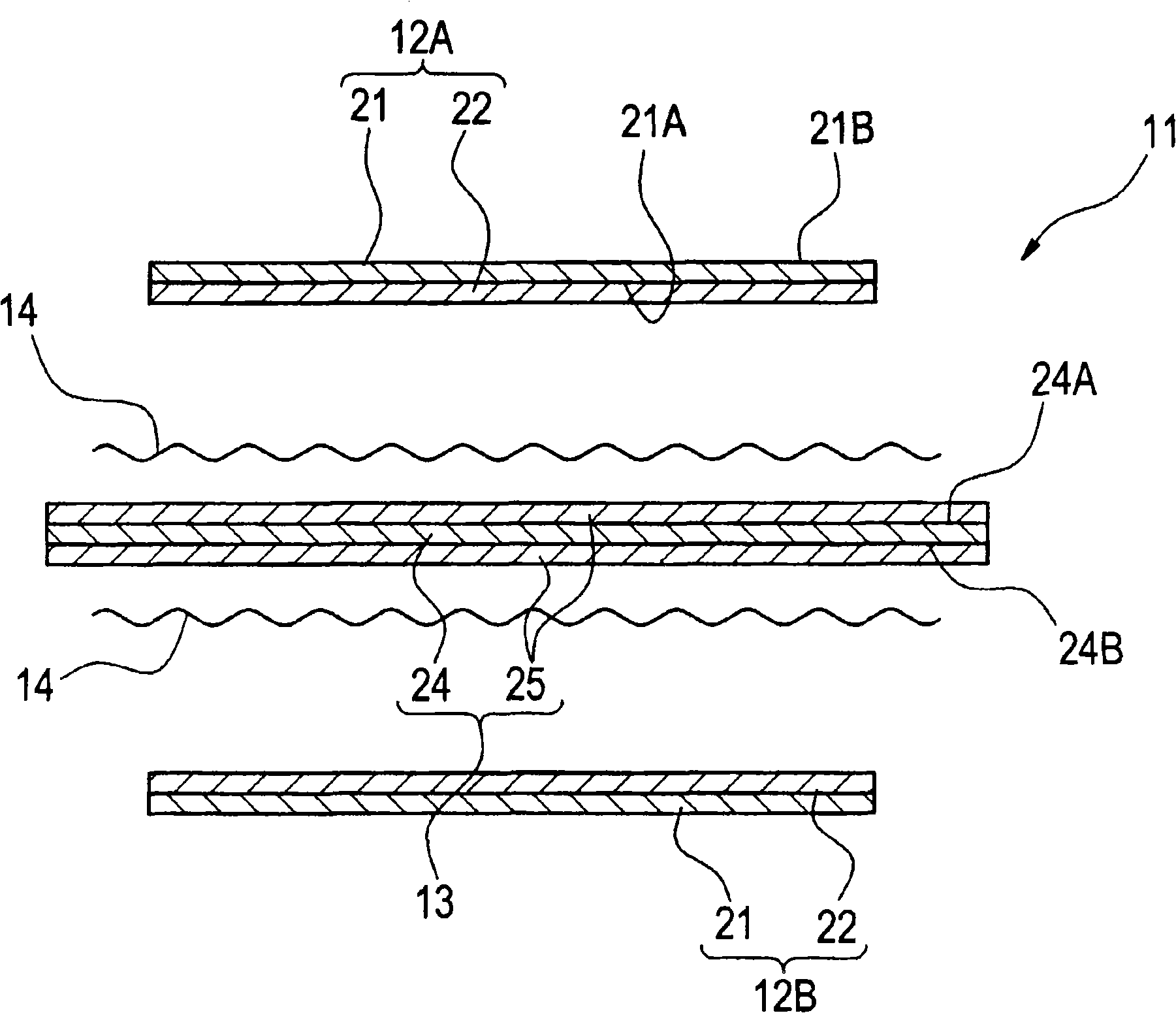

[0038] Such as image 3 As shown, in each of the first positive electrode 12A and the second positive electrode 12B, the positive electrode active material layer 22 is uniformly coated on one surface of...

no. 2 approach

[0060] in such as Figure 7 ~ Figure 8 In the non-aqueous electrolyte secondary battery 50 in the illustrated second embodiment, the contact piece 52 is provided at the end 51A of the negative terminal 51 .

[0061] The contact piece 52 extends in the thickness direction of the negative terminal 51 and has a cylindrical shape having a tapered tip portion 52A. The length of the contact sheet 52 in the longitudinal direction is the length extending across the multilayer edge 13A which is stacked based on the winding of the negative electrode 13 .

[0062] In this nonaqueous electrolyte secondary battery 50 , the contact piece 52 of the negative terminal 51 generally penetrates the edge 13A of the negative terminal 51 in the thickness direction.

[0063] Under this condition, a through hole as a division 53 is formed in the edge 13A of the negative electrode 13 through the contact piece 52 , and the negative electrode current collector (copper foil) 24 of the negative electrode ...

no. 3 approach

[0067] in such as Figure 9 In the non-aqueous electrolyte secondary battery of the third embodiment shown, a pair of contact pieces 61 and 62 are provided at the positions of the pair of contact pieces 31 of the first embodiment, and other configurations are the same as those of the non-aqueous electrolyte secondary battery in the first embodiment. The electrolyte secondary battery 10 is the same.

[0068] In the contact piece 61 , the lower side 61A is formed with an ascending gradient from the end portion 16A toward the distal direction; in the contact piece 62 , the lower side 61A is formed with an ascending gradient toward the proximal direction of the end portion 16A.

[0069] Such as Figure 10 As shown, in the negative electrode terminal 60, when the negative electrode 13 is divided by the contact pieces 61 and 62 from the edge 13A along the plane direction of the negative electrode 13, the lower side 61A of the contact surface 61 can be along the Figure 10 to guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com