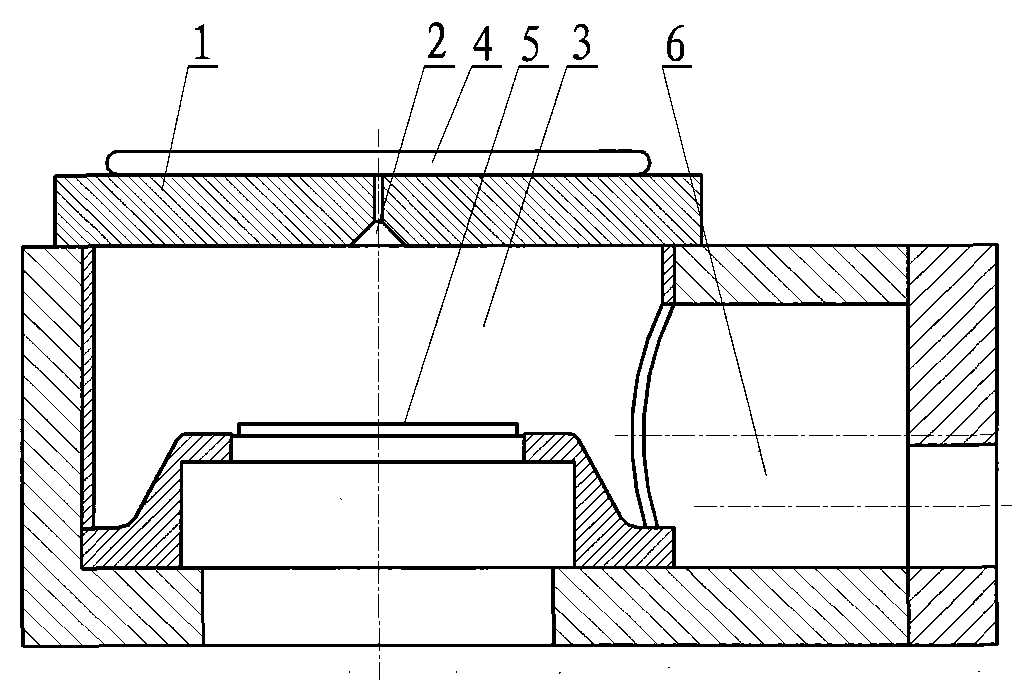

Inductance coupling plasma apparatus

A plasma and inductive coupling technology, applied in the direction of plasma, circuits, electrical components, etc., can solve the problems of lower product yield, poor etching uniformity, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

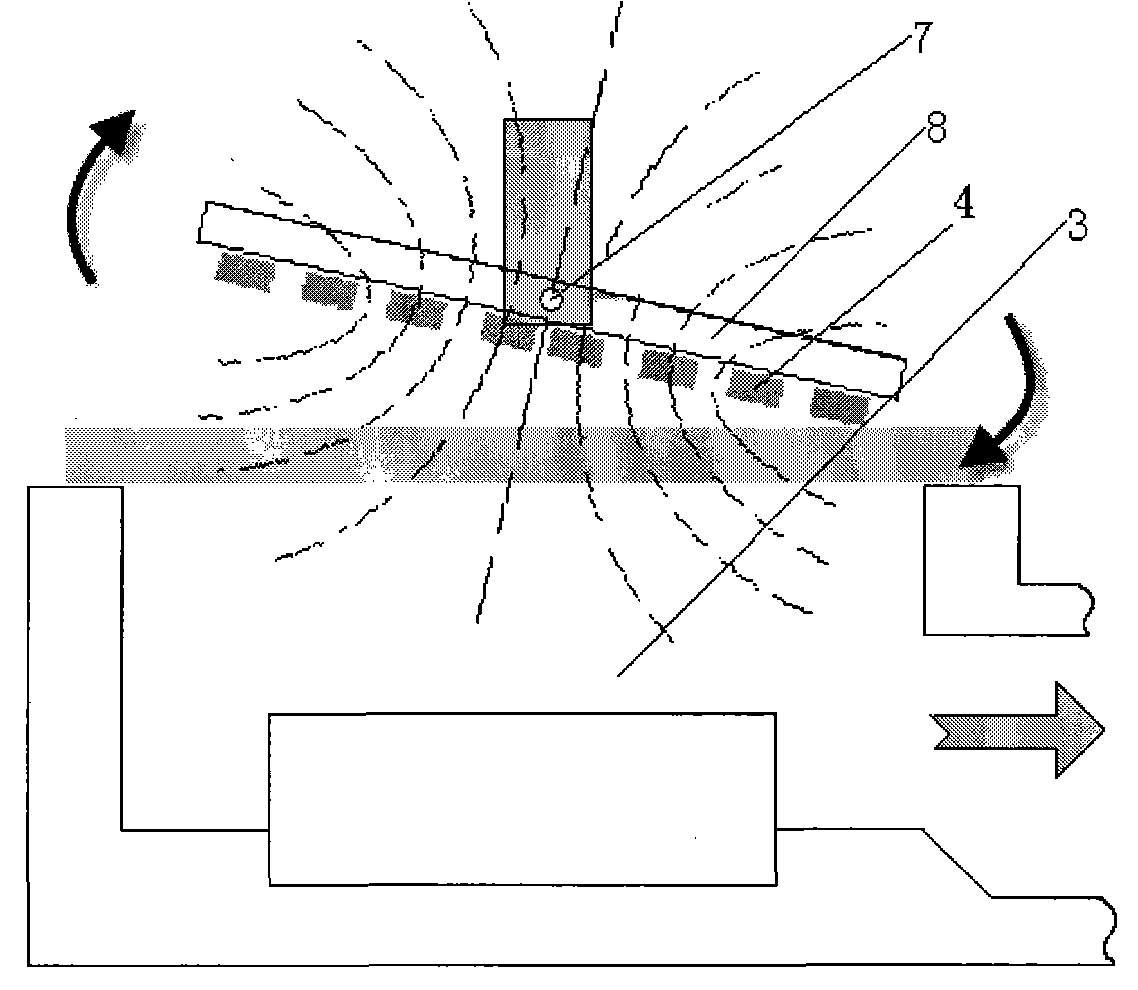

[0018] In the second specific embodiment, the connecting device includes two horizontal axes, and the two horizontal axes are perpendicular to each other, and the inductively coupled coil 4 can rotate around any one of the horizontal axes. Two mutually perpendicular horizontal axes constitute a directional connection device, so that the inductively coupled coil 4 can be inclined in any direction relative to the reaction chamber 3 .

specific Embodiment 3

[0019] In the third specific embodiment, the connecting device further includes a vertical axis, and the inductively coupled coil can rotate around the vertical axis and the horizontal axis. A universal connection device can also be formed so that the inductively coupled coil 4 can be inclined in any direction relative to the reaction chamber 3 .

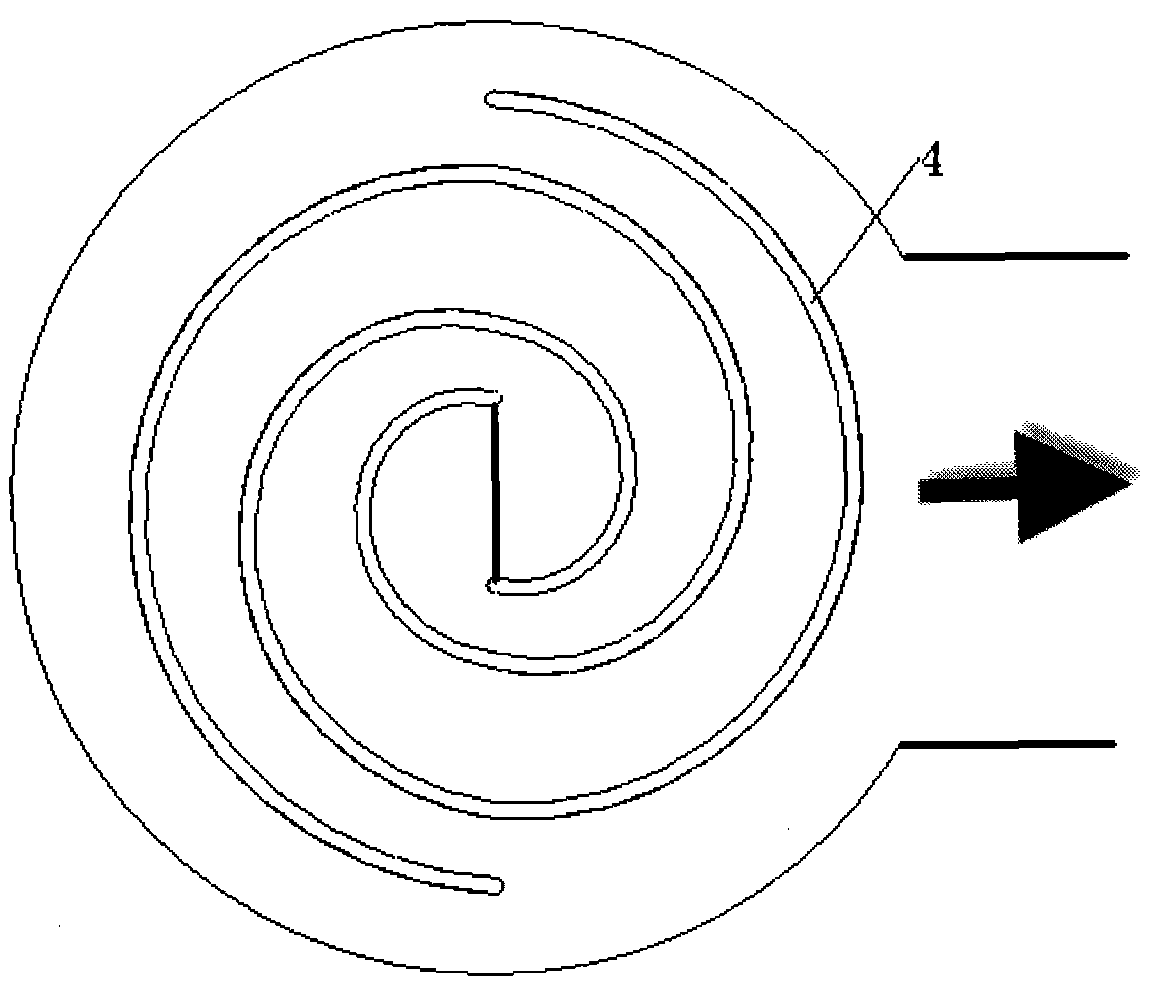

[0020] In general, the plane of the inductively coupled coil 4 is parallel to the plane of the quartz cover above the reaction chamber 3 and the plane of the wafer. When the mechanical structure of the reaction chamber 3 and the way of pumping air are completely symmetrical, the coil placed horizontally has a good effect. , However, when the mechanical structure of the reaction chamber 3 is asymmetric, the inherent central symmetry of the coil is destroyed, resulting in an eccentric phenomenon in the etching rate distribution.

[0021] The present invention can properly adjust the inclination angle between the coil and the quartz co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap