Method and device for directly coupling hollow-core photonic band gap optical fiber ring and integrated optical chip based on composite light guide mechanism

A technology of photonic bandgap and integrated optics, which is applied in the field of optical fiber device manufacturing, can solve problems such as hindering the development of hollow-core photonic bandgap fiber optic gyroscopes, destroying the reciprocity and symmetry of optical paths, and large losses in pigtail welding methods. Unreliability, eliminate the influence of optical path reciprocity and symmetry, and improve the effect of environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be further described in detail and in-depth below in conjunction with the accompanying drawings.

[0028] First, the direct coupling device between the hollow-core photonic bandgap fiber ring and the integrated optical chip based on the composite light guiding mechanism realized by the present invention is described.

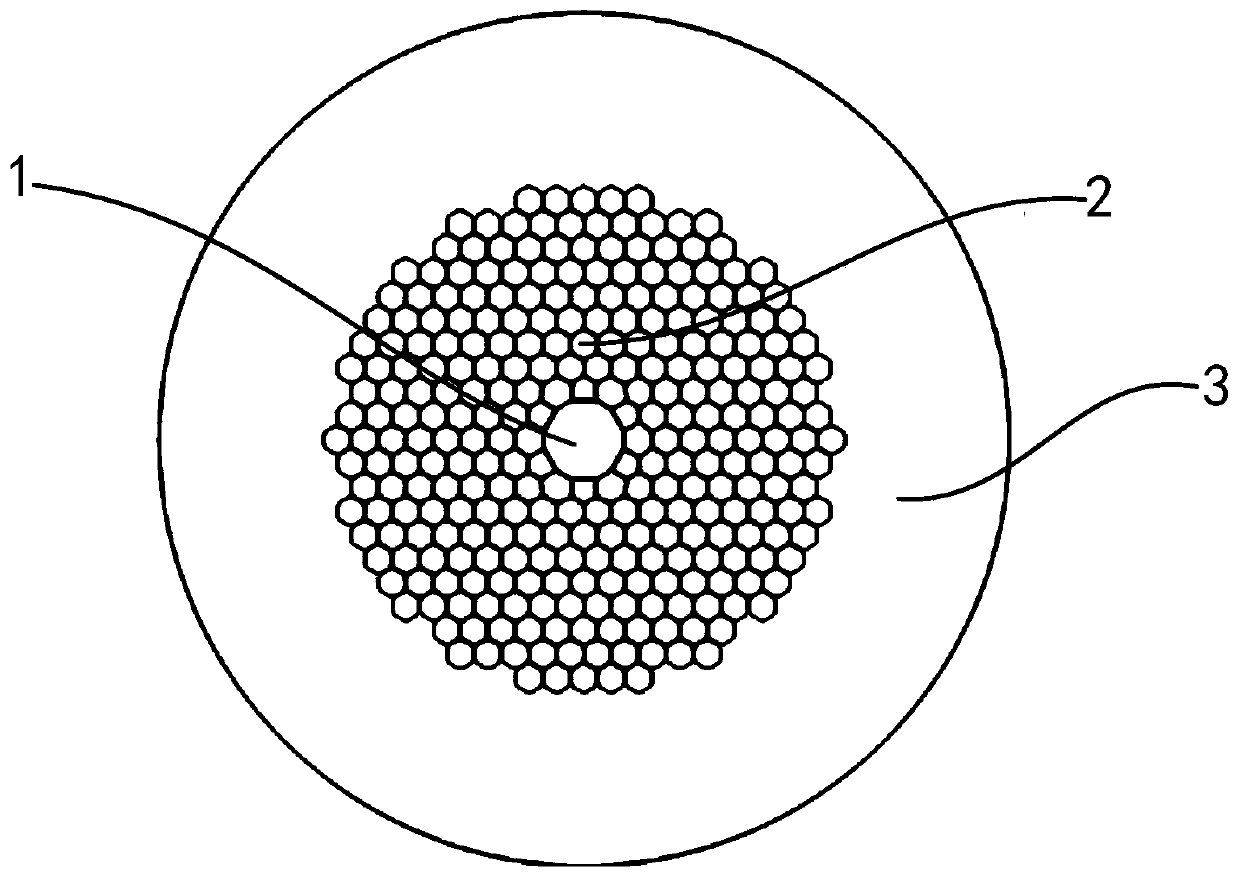

[0029] Such as figure 1 As shown, the end face structure of the hollow-core photonic bandgap fiber used in the present invention includes a large core air hole 1 , a cladding small air hole 2 and a cladding quartz layer 3 .

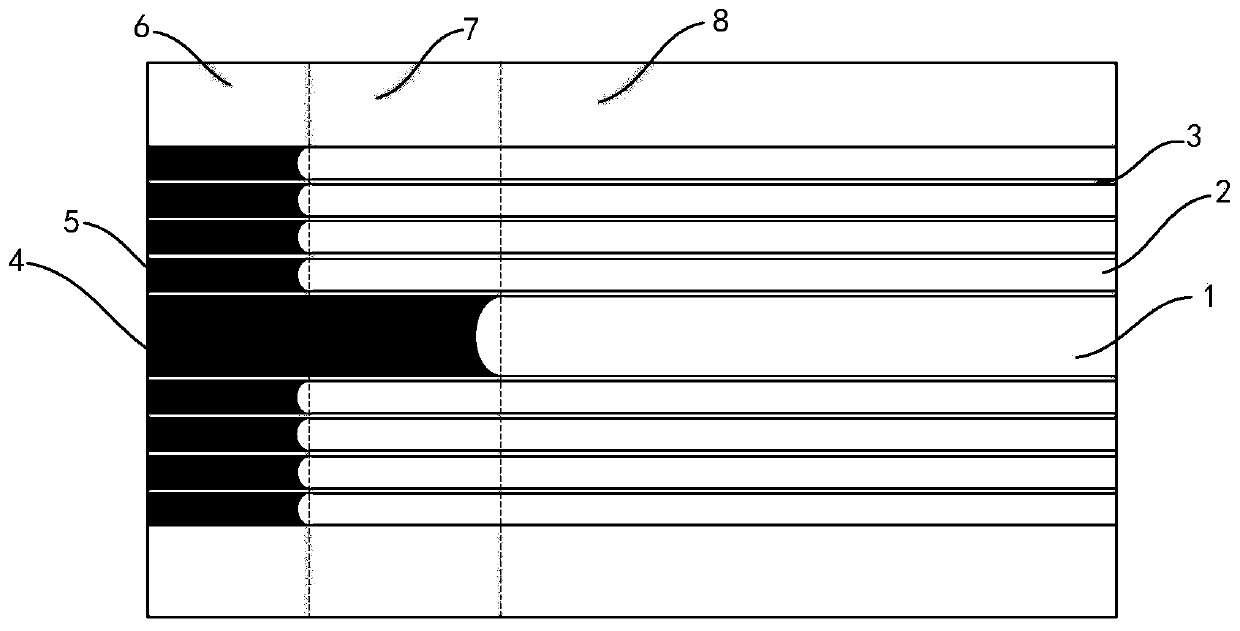

[0030] Such as figure 2 As shown, the present invention injects high-refractive-index optical glue 4 into the large core air hole 1 on the end face of the hollow-core photonic bandgap fiber, and injects low-refractive-index optical glue 5 into the cladding small air hole 2 . Mark the part of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com