A segmented control type liquid nitrogen freezer and its working method

A technology of segmented control and working method, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of inability to stop the freezing of the upper strata, increasing construction costs, and poor uniformity of frozen walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present application will be further described below in conjunction with the accompanying drawings.

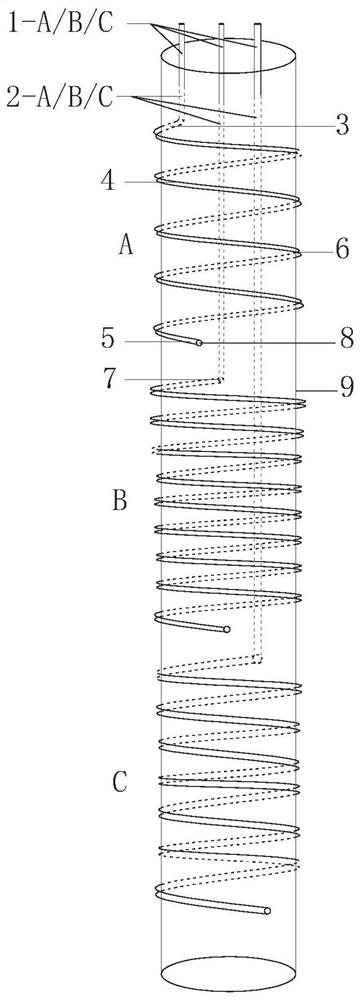

[0021] Such as figure 1 As shown, the segmented control type liquid nitrogen freezer of the present invention includes a gas return steel pipe 9, the size of the gas return steel pipe 9 matches the borehole that needs to be frozen, and the outer side of the gas return steel pipe 9 is arranged according to the actual need to freeze the borehole wall area. Multi-section spiral liquid supply pipe 4, the upper end 3 of each section spiral liquid supply pipe 4 is welded with the vertical pipe 2 extending to the top of the gas return steel pipe 9, and the top of the vertical pipe 2 is provided with a liquid supply nozzle 1, said The vertical pipe 2 adopts heat-insulated resin pipes, and the vertical pipe 2 is arranged on the outside of the air return steel pipe 9 or inside the air return steel pipe 9. When the vertical pipe 2 is arranged inside the air retur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap