Fuel cell

A fuel cell and electrode assembly technology, which is applied to fuel cells, fuel cell groups, and fuel cell components, etc., and can solve problems such as failures and mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

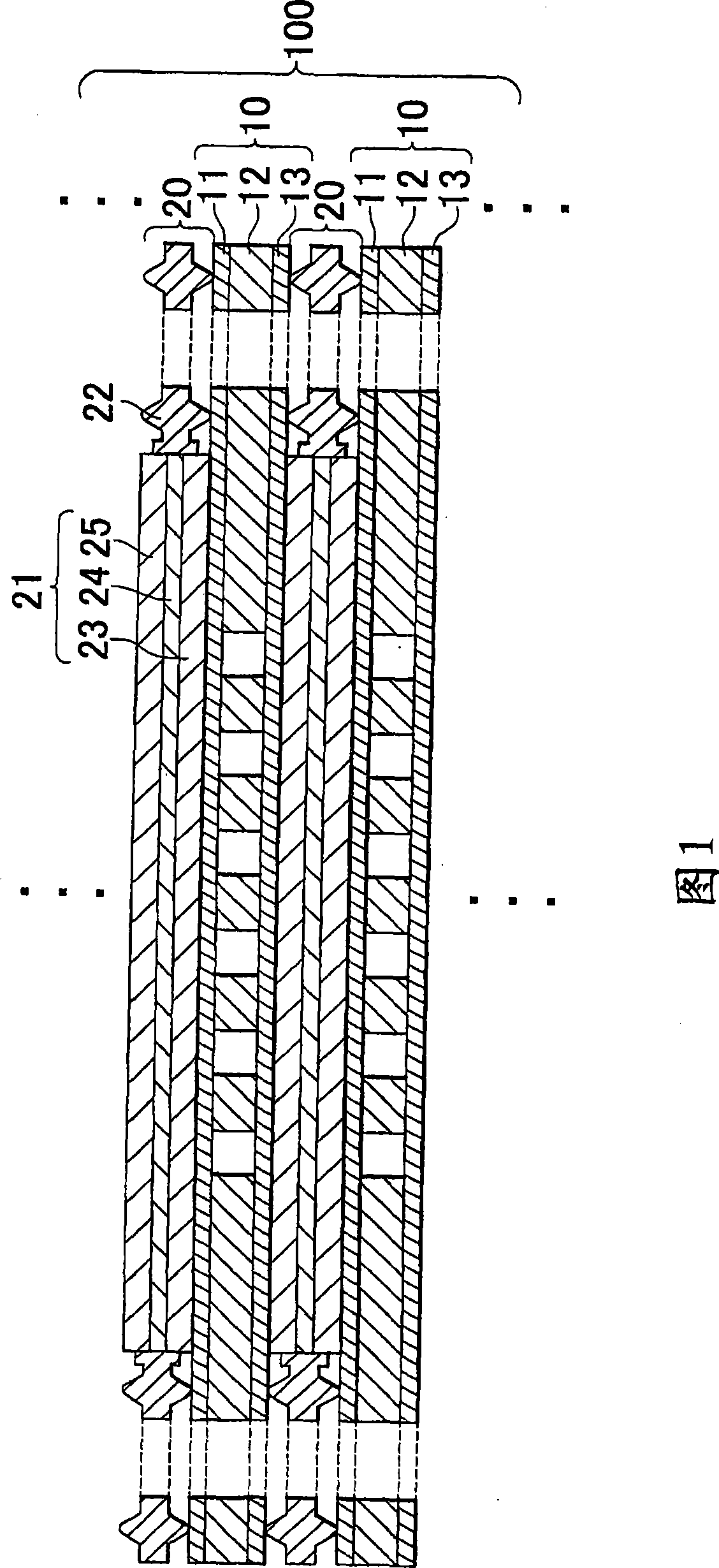

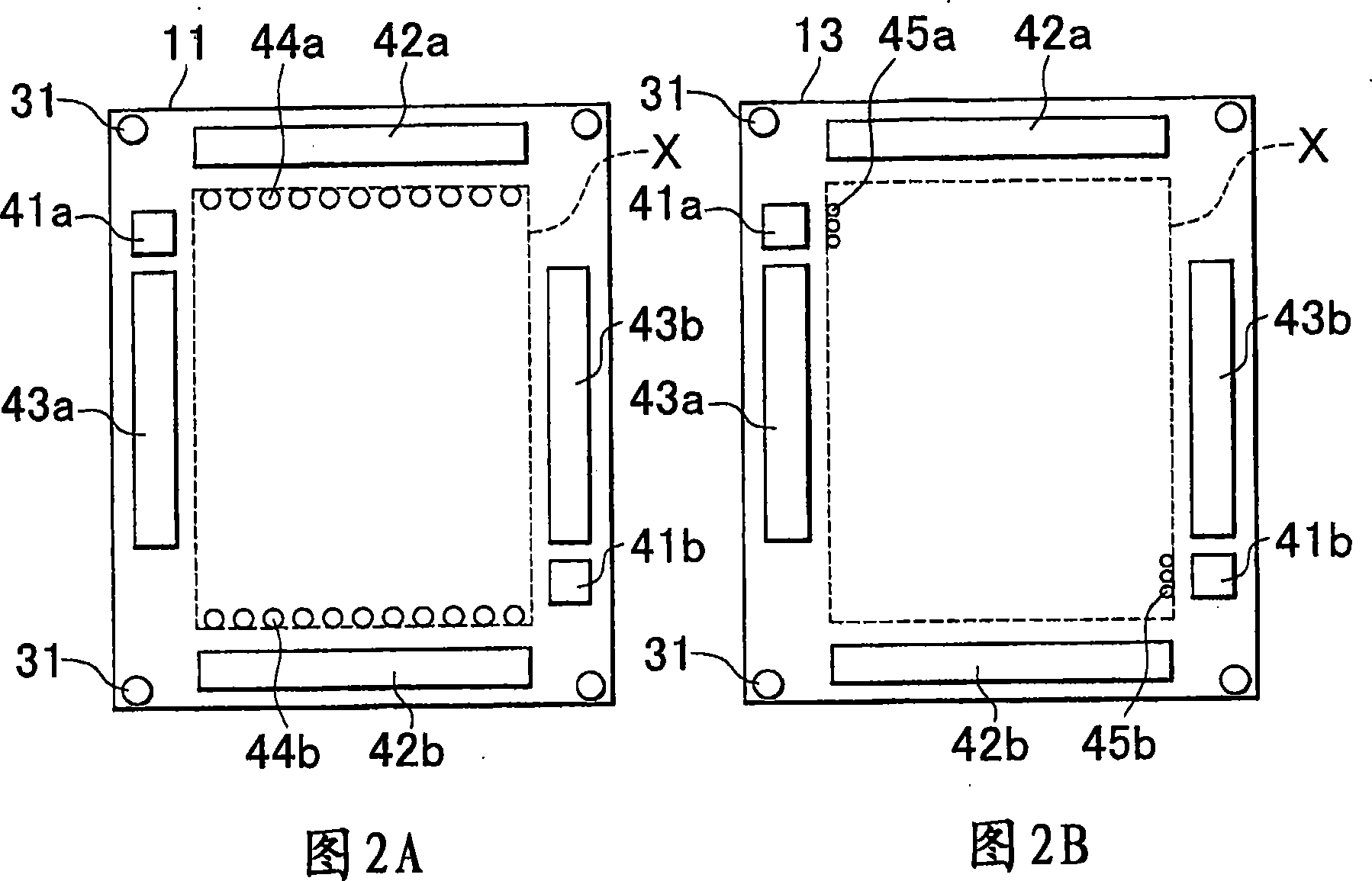

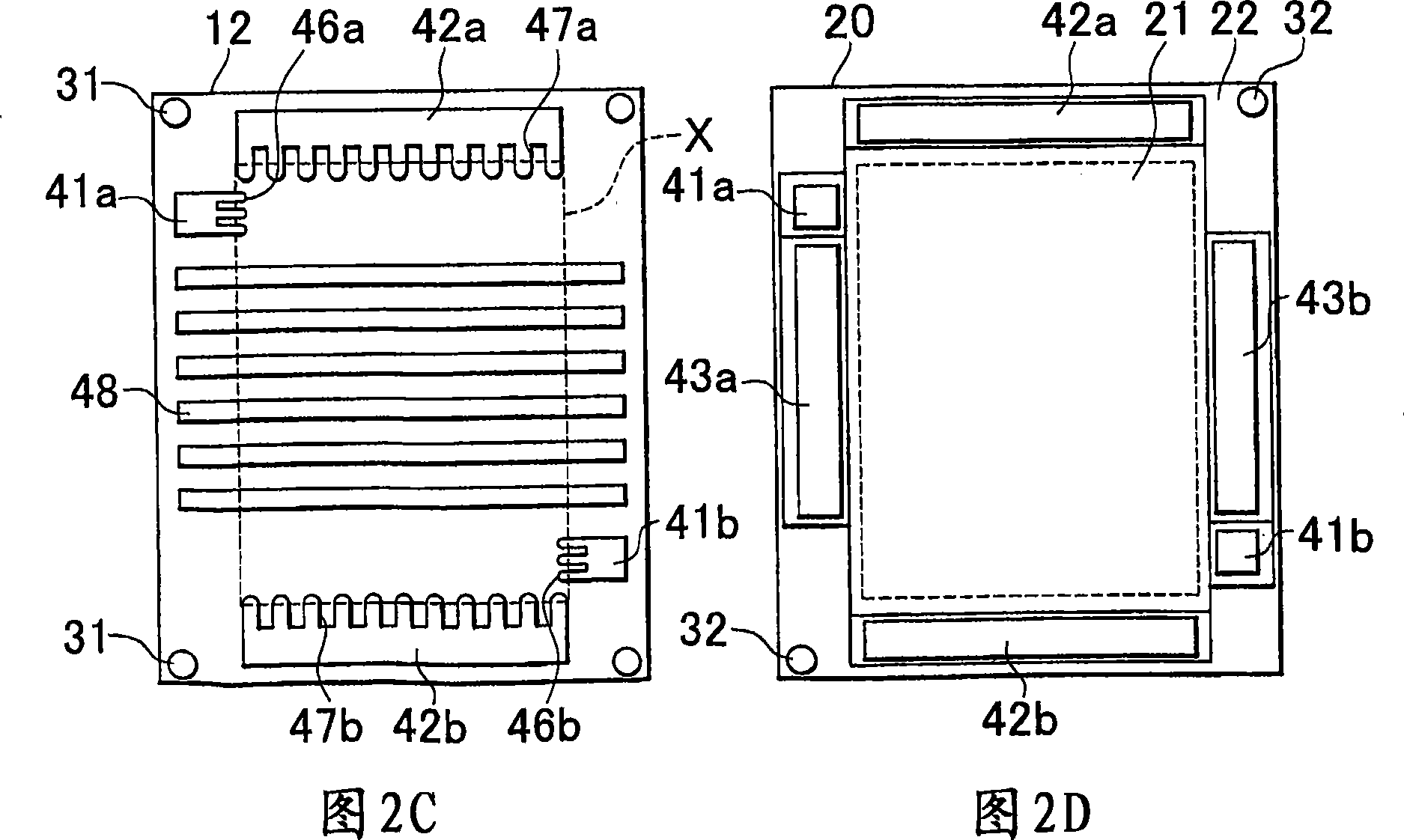

[0018] FIG. 1 is a view schematically showing a fuel cell 100 according to a first embodiment of the present invention. As shown in FIG. 1, the fuel cell 100 has a structure in which separators 10 and gasket-combined membrane electrode assemblies 20 are stacked alternately on top of each other. Each separator 10 has a structure in which an intermediate plate 12 is sandwiched between a cathode-facing plate 11 and an anode-facing plate 13 . These three plates 11 , 12 and 13 forming the separator 10 can be fitted to each other, for example by thermocompression.

[0019] Each gasket-combined membrane electrode assembly 20 includes a membrane electrode assembly (MEA) 21 and a gasket part 22 . The membrane electrode assembly 21 includes: a power generation part 24, in which a catalyst layer is formed on each face of an electrolyte membrane h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com