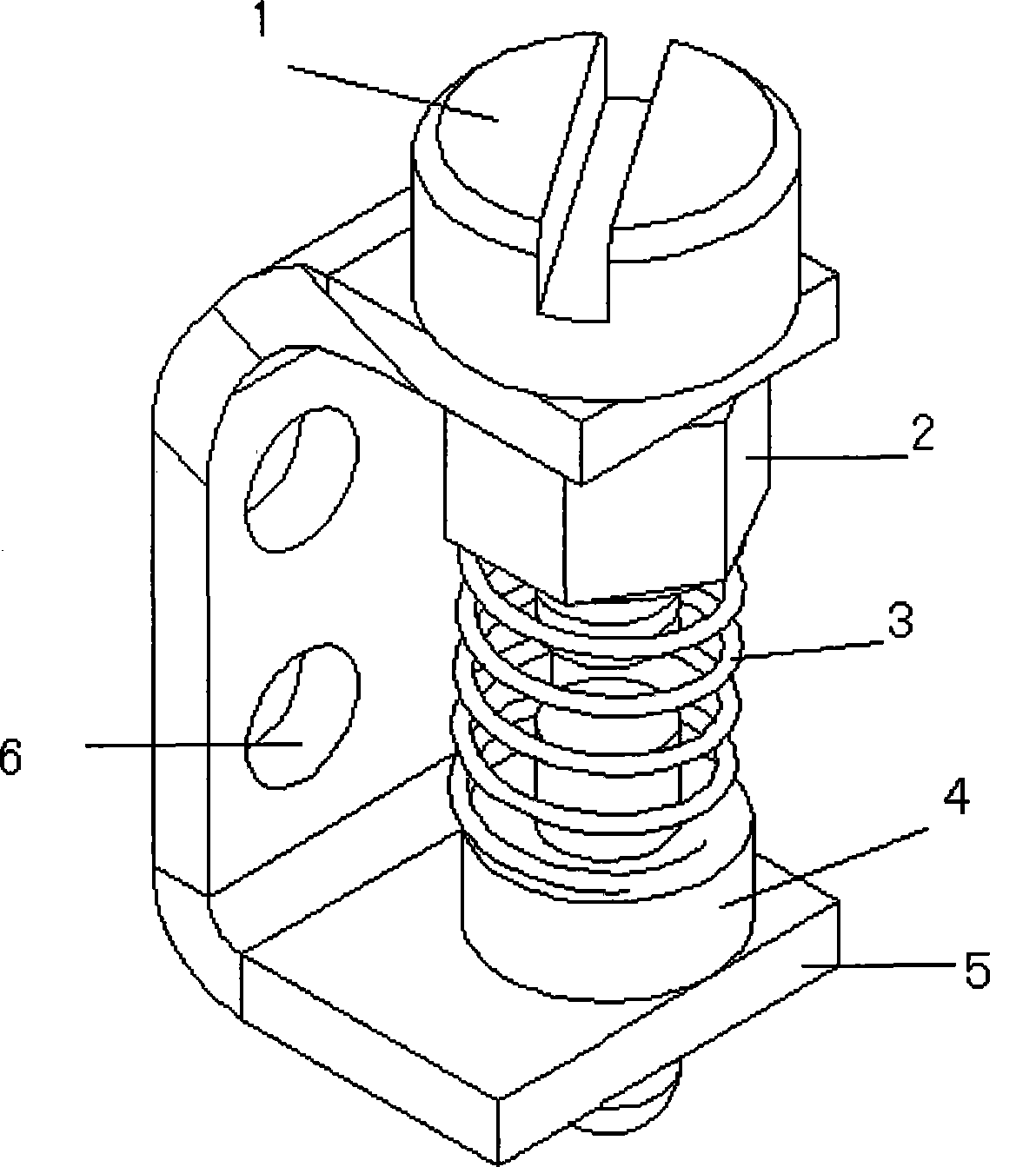

Adjustment mechanism for presser foot for connection in pattern machine

A technology of adjusting mechanism and pattern machine, which is applied in the direction of cloth pressing mechanism, sewing machine components, textile and paper making, etc., can solve the problem of inconvenient adjustment of the height of the presser foot, and achieve the effect of buffering and easy adjustment of the middle presser foot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

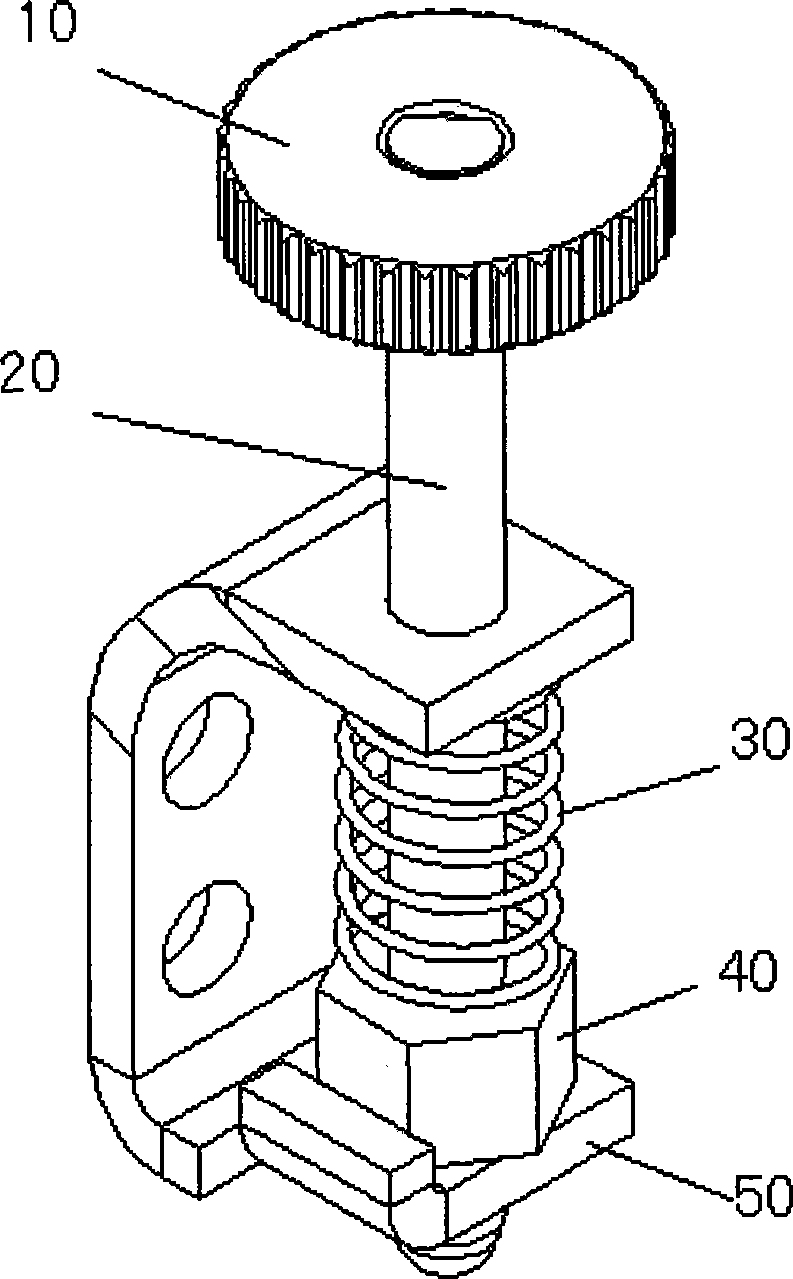

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0011] Depend on figure 2 It can be seen that the present invention includes: a support frame 50; an adjustment rod 20 that passes through the support frame 50 and is in contact with the middle presser mechanism, and can be adjusted up and down; also includes: a nut 40 placed on the lower surface of the support frame 50 , one end is connected to the nut 40, and the other end is connected to the spring 30 under the upper surface of the support frame 50; a knob 10 is also arranged on the top of the adjustment rod 20, and the adjustment rod 20 is screwed to the nut 40;

[0012] The nut 40 is a stop nut.

[0013] The present invention utilizes the thread characteristics to expose the knob on the head of the adjusting rod to the outside of the machine head, so that when adjusting the height of the intermediate presser foot, there is no need to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com