Self-water supply quick vapor generator

A steam generator, fast technology, applied in the direction of steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problem of large water tank capacity, long preheating to boiling time, adding water and pouring out residual water and cleaning problems. Very convenient and other problems, to achieve the effect of reducing heating space, shortening the time of occurrence, and convenient for residual water and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

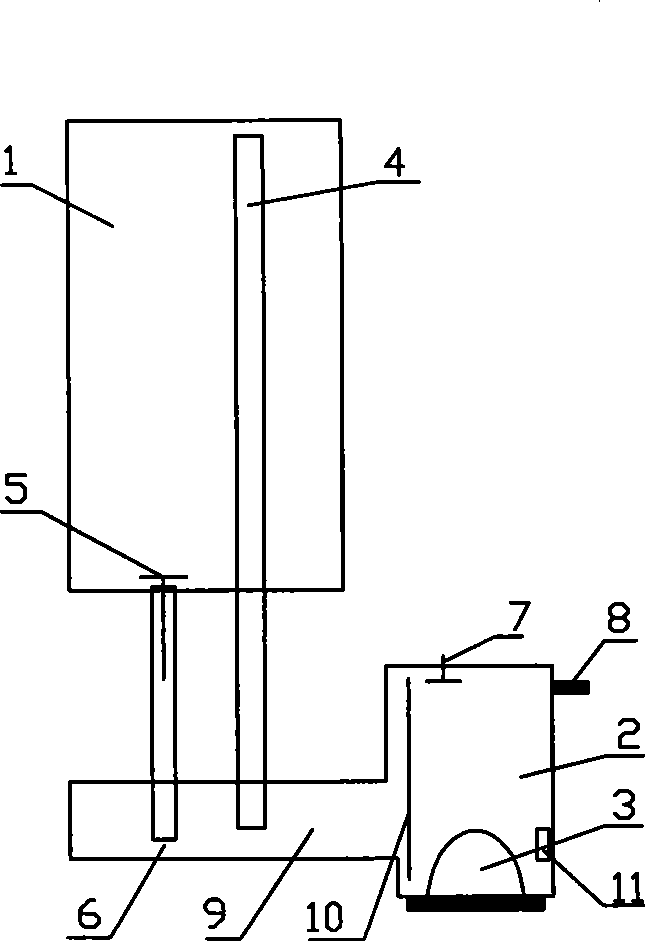

[0024] Such as figure 1 The shown self-supply water fast steam generator that can separate the water tank includes a water supply tank 1 and a heating chamber 2 equipped with an electric heating tube 3 . The heating chamber 2 and the water supply tank 1 are separate and independent components. The heating chamber 2 is provided with a connecting platform forming a water supply channel with the water supply tank 1, a steam outlet 8 and an air inlet check valve 7 for balancing pressure. Dry boiling water level control assembly 11. The space of the heating chamber below the connection table is connected to the heating space of the heating chamber, but there is a partition 10 between which reduces the heating space to shorten the heating time of the steam, and is provided with a water supply to control the one-way entry of water from the water supply tank 1 into the heating chamber 2 One-way valve 5 and the balance pipe 4 that controls water to keep the balanced water surface in t...

specific Embodiment approach 2

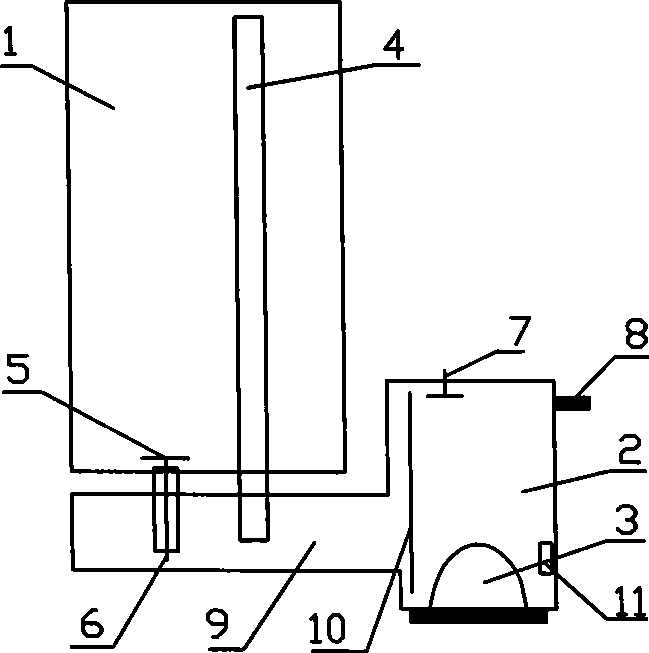

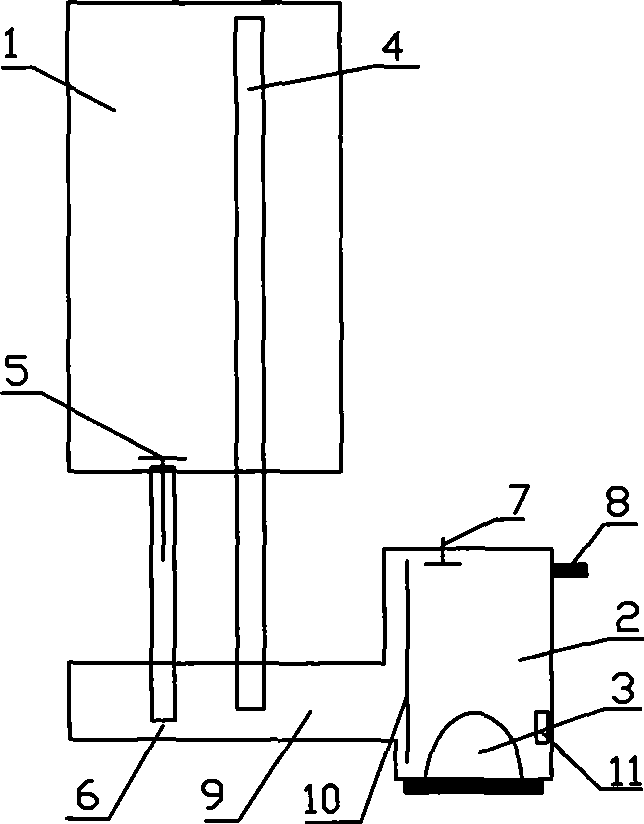

[0029] Such as figure 2 The shown self-supply water fast steam generator that can separate the water tank differs from the specific embodiment 1 in that the water supply tank 1 is arranged outside the connecting platform through the connecting pipe ( figure 2 (not shown in the middle) is connected with the heating chamber space below the connecting platform, the water supply check valve 5 that controls water to enter the heating chamber 2 in one direction from the water supply tank 1 and the balance pipe 4 that controls the water to maintain a balanced water surface 9 in the heating chamber 2 in the connecting pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com