Demagnetization method for permanent recuperation magnet steel by made-to-measure demagnetization clamper

A permanent magnet and demagnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of re-magnetization of magnet steel, scrapping of complete machine products, and difficulty in demagnetization, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

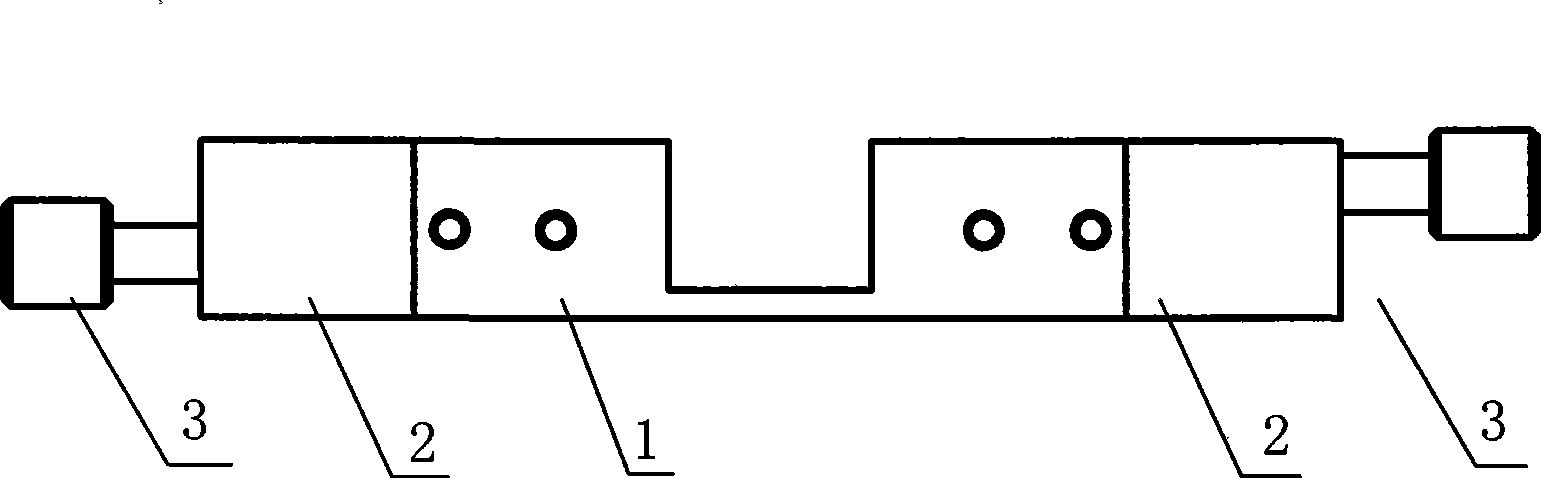

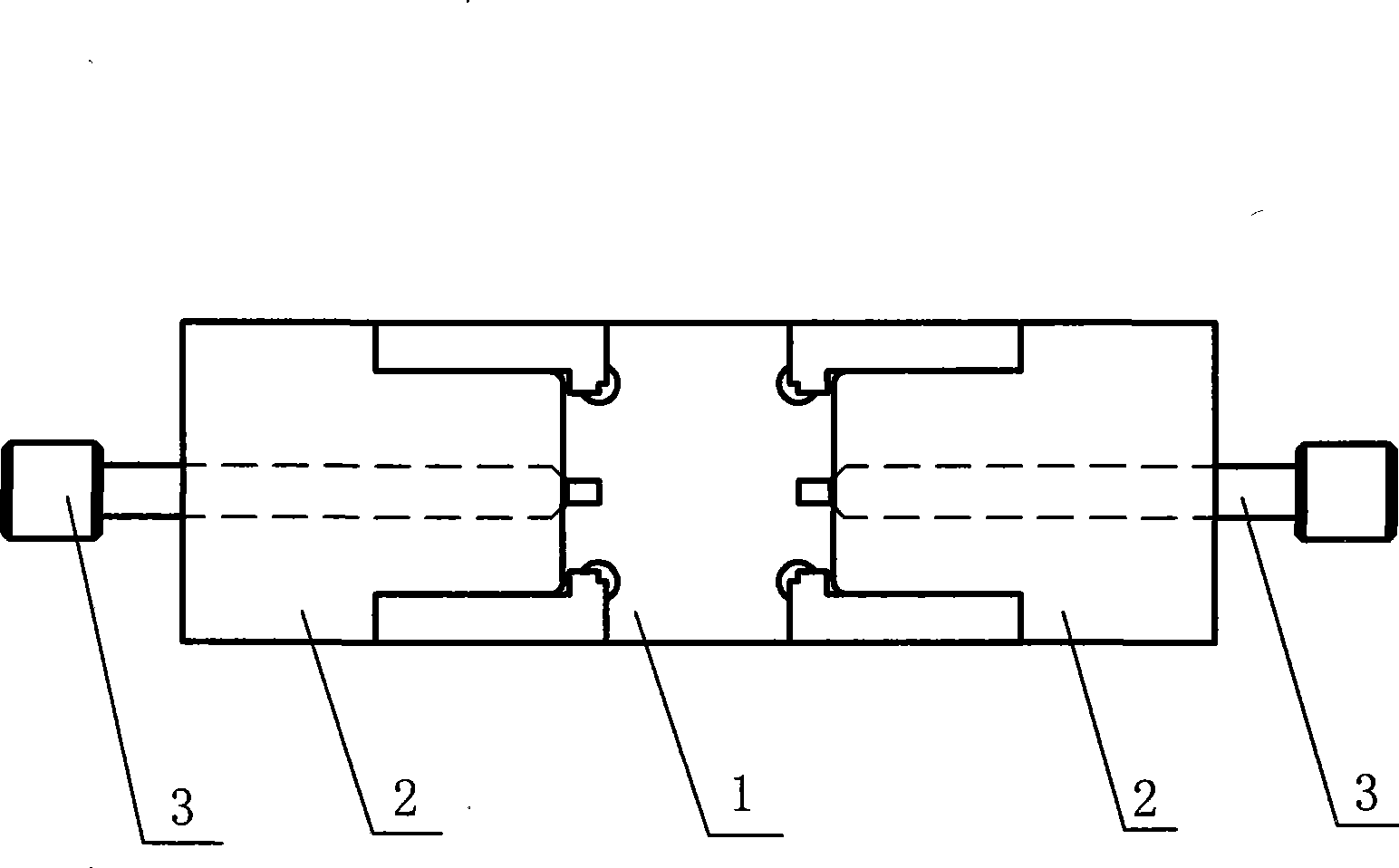

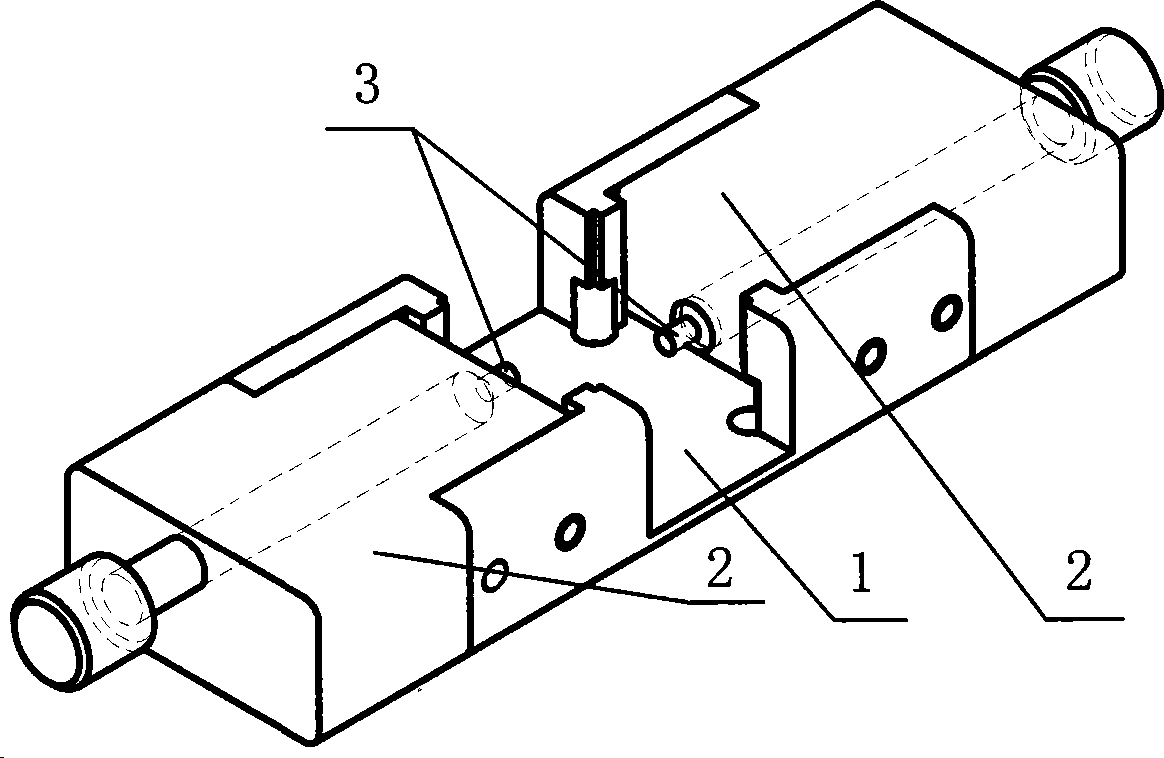

[0017] With reference to the accompanying drawings, the special demagnetization fixture of the present invention is further described to the permanent restoration magnetic steel demagnetization method and the embodiment. The special demagnetization fixture is composed of a clamp body 1, a fixed magnetic pole 2, and a movable magnetic pole 3. The fixed magnetic pole 2 and the movable magnetic pole are in pairs. The magnetic poles 3 are arranged symmetrically at both ends of the clip body 1. The clip body 1 is made of high magnetic resistance material. The paired fixed magnetic poles 2 and movable magnetic poles 3 at both ends of the clip body 1 are made of soft magnetic materials and have poles. Excellent magnetic permeability, the fixed magnetic pole 2 concentrates the magnetic flux generated by the AC coil in the magnetic circuit of the fixture, so that one end of the movable magnetic pole 3 is in direct contact with the permanent restoration magnet, and the other end is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com