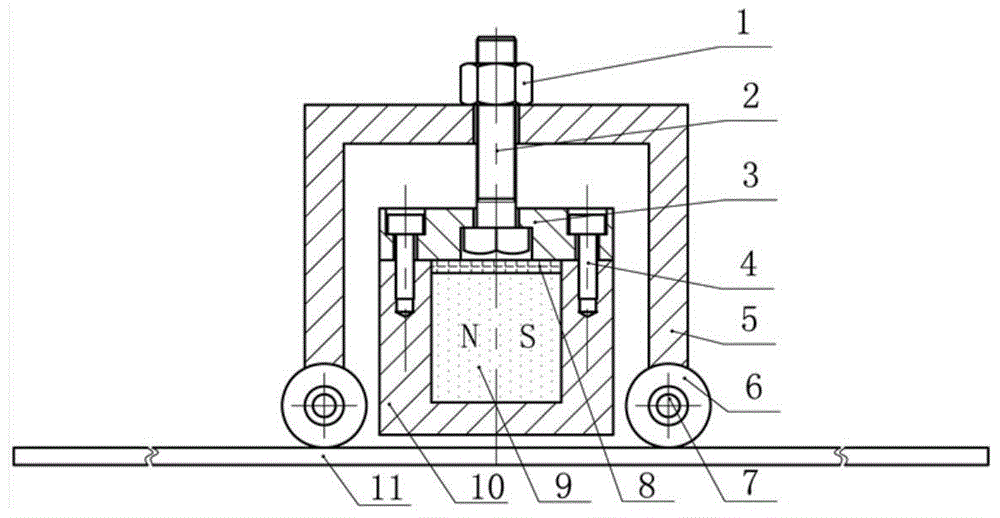

A method and device for demagnetizing a ferromagnetic elongated member

A slender component, ferromagnetic technology, applied in the field of electromagnetic non-destructive testing of ferromagnetic components, can solve the problems of complex overall structure of the device, difficult heating, inconvenient operation, etc., and achieve the effects of simple structure, convenient demagnetization, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

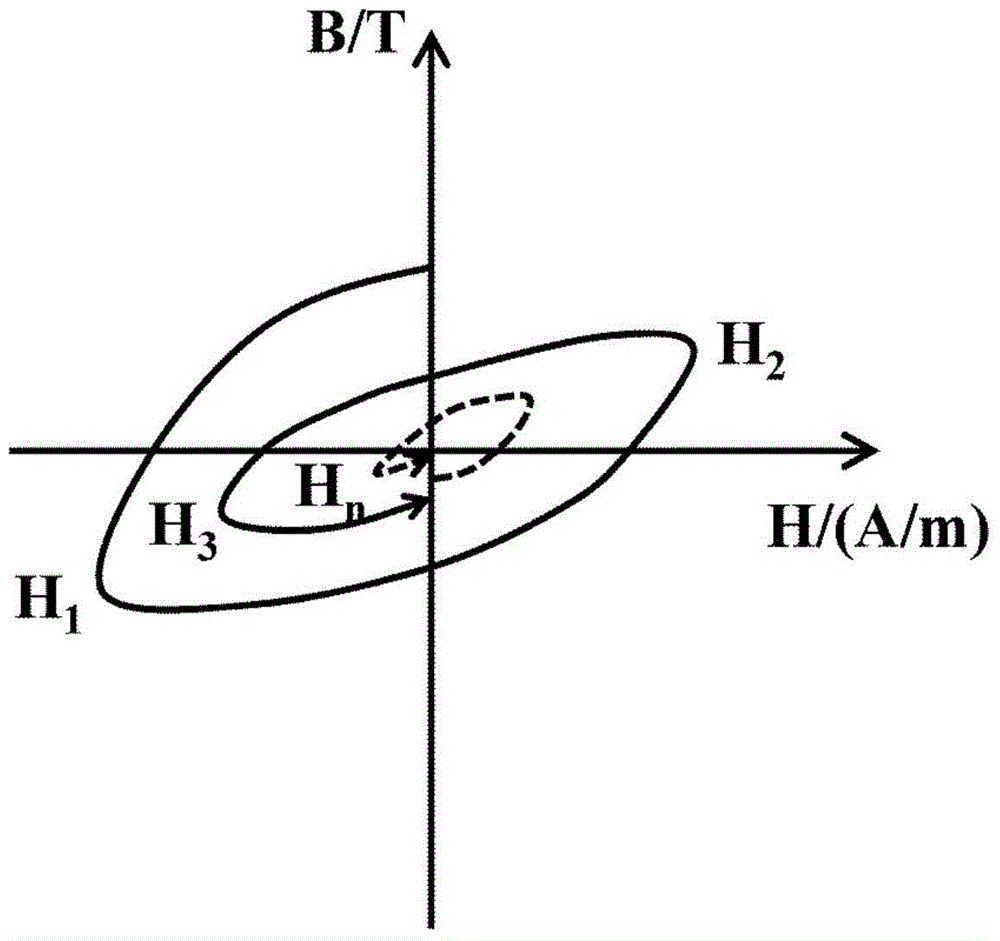

[0039] The present embodiment adopts three steel rods with an outer diameter of 20 mm and a length of 1 m as demagnetization objects, respectively measure the axial residual magnetic induction intensity at the ends of steel rods a and b before demagnetization, and steel rods a and b after demagnetization using the method described in the present invention. The axial residual magnetic induction intensity at the b end is used to analyze and illustrate the demagnetization effect of the method of the present invention, and the direction of the magnetic induction intensity is defined as positive to the right, and the measurement results are as shown in Table 1.

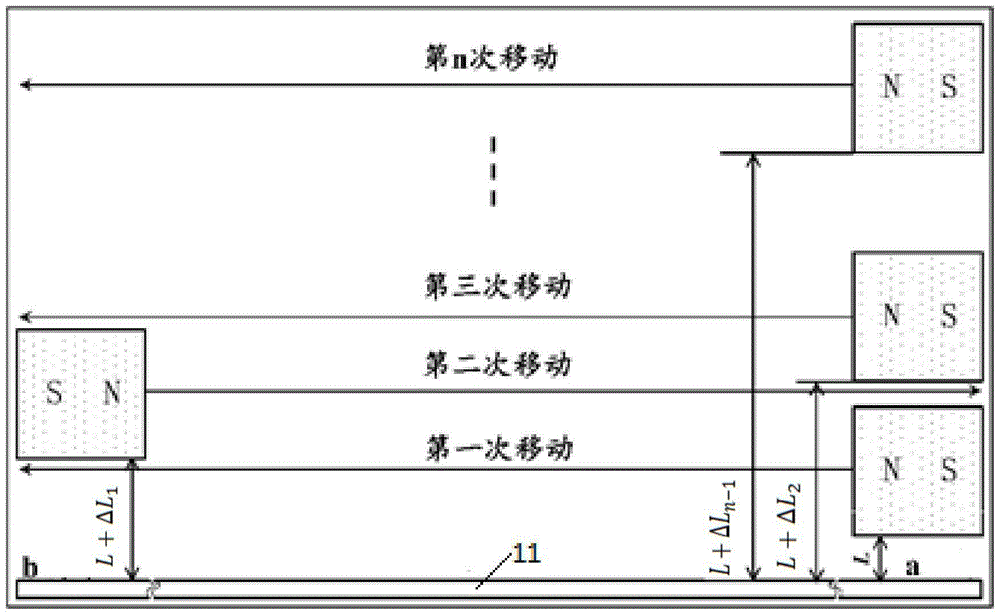

[0040] It specifically includes the following steps:

[0041] 1) According to the ferromagnetic slender member to be demagnetized, the permanent magnet used to provide the magnetic field is selected mainly according to the residual magnetic strength, coercive force and cross-sectional size of the member, and the performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com