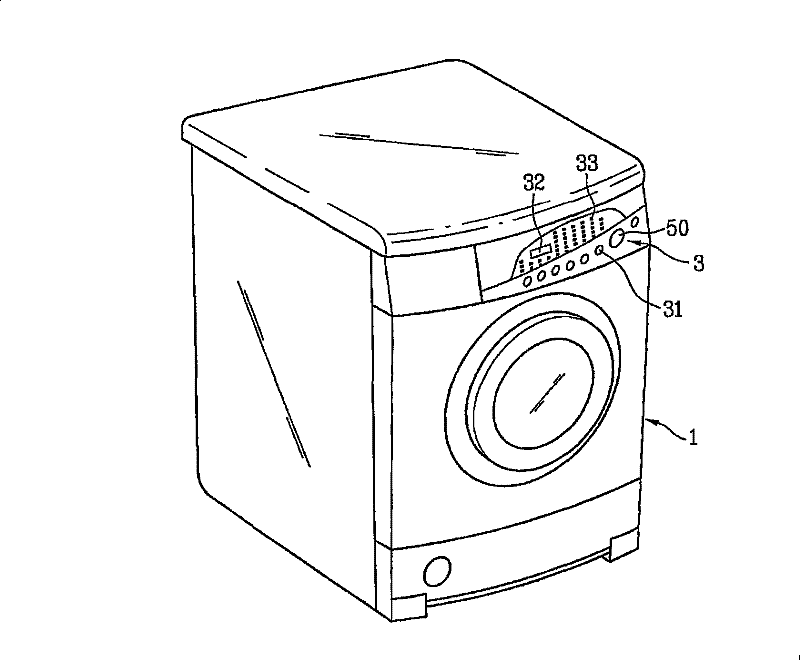

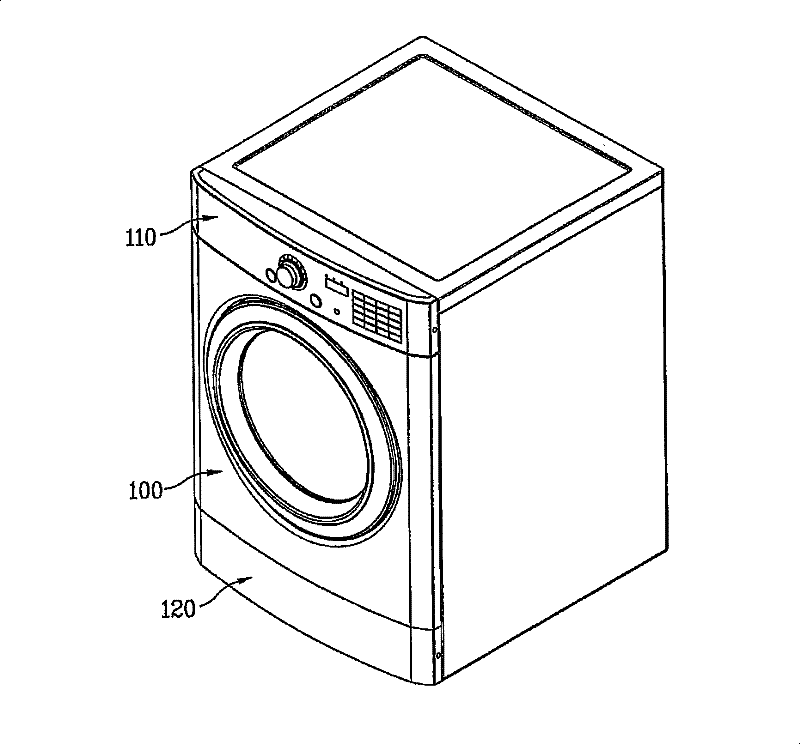

Laundry machine having changeable controlling part and dual laundry machine having the same

A washing machine and variable technology, applied in the field of washing machines, can solve the problems of not easy access to the controller, inconvenient use of washing machines and dryers, inconvenient looking up at the display unit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

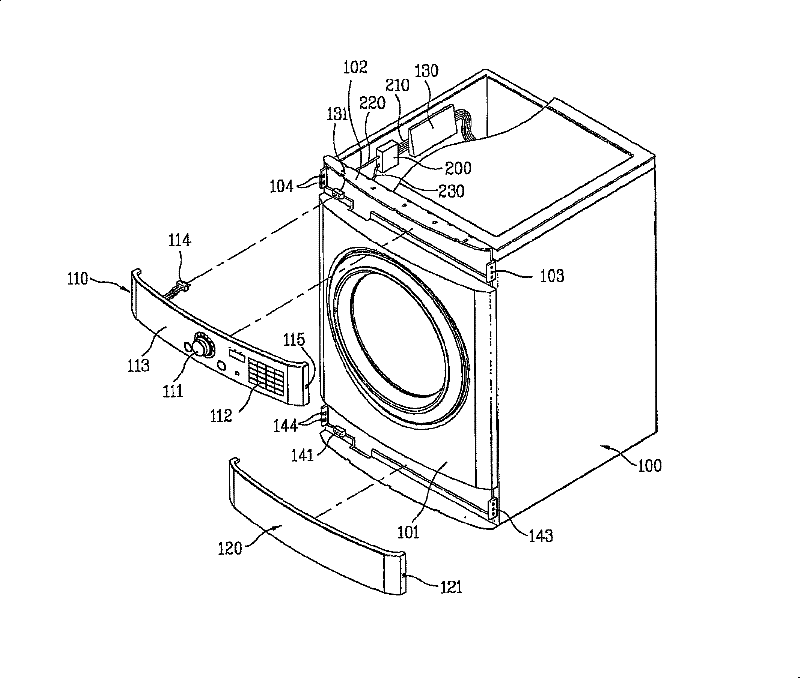

[0122] Figure 7 and Figure 8 Other embodiments are shown respectively. The washing machine in this embodiment is basically the same as the previous embodiment, but the method is different in that the main control unit 130 is electrically connected to the upper connector 231 and the lower connector 241 .

[0123] In this embodiment, there are no jumper connectors, and drop cables 250 are used. As shown, one end of the cable is connected to the main control unit 130, and the other end is divided into two branch lines. Therefore, two branch lines of the branch cable are connected to the upper connector 231 and the lower connector 241 .

[0124] Figure 9 Another embodiment is shown in which the control unit 130, the upper connector 331 and the lower connector 341 are connected in another way. Here, a cable 350 for connecting the main control unit 130 to the upper connector 331 and a cable 351 for connecting the main control unit 130 to the lower connector 341 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com