One-time pull-off vibration filter plate filter press and vibration method

A technology of filter press and filter plate, which is applied in the field of one-time pull-off vibrating filter plate filter press, can solve the problems of high labor intensity, difficulty in automatic control, unsatisfactory cake unloading effect, etc., and achieve low work efficiency, unloading cake ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

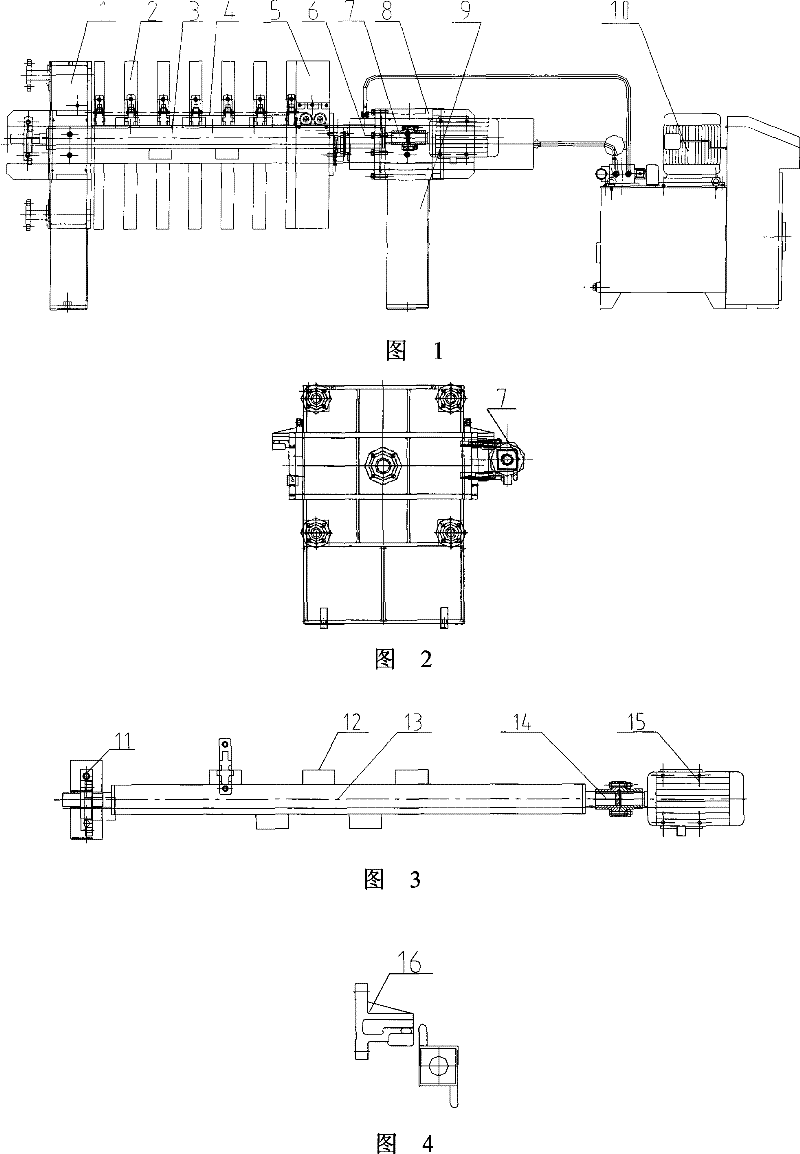

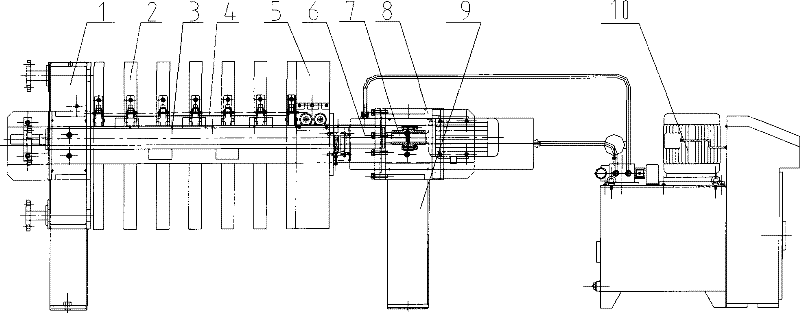

[0012] Embodiment 1: with reference to attached Figure 1~4 . One time pull the vibrating filter plate filter press, which includes a thrust plate 1, a filter assembly 2, a main beam 3, a compression plate 5, an oil cylinder 6, an oil cylinder seat 8, a frame 9 and a hydraulic system 10, and the frame 9 is used for Support filter assembly 2, and connect other parts, it is mainly made up of components such as thrust plate 1, main beam 3, oil cylinder 8, oil cylinder 6 and pressure plate 5. The pull plate system 4 connects each filter plate and the pressing plate 5 of the filter assembly 2 (the connection refers to: the handles on the side of multiple filter plates are connected by the pull plate belt spacing), that is to say, the pull plate system 4 is formed by pulling The plate belt and the connecting piece are formed, and the pulling plate belt is connected with the plurality of filter plates and the pressing plate 5 in the filter assembly 2 at intervals through the connect...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the vibration method of pulling apart the vibrating filter plate filter press at one time, after the pressing of the filter press is completed, when the piston in the oil cylinder 6 moves back, it is driven by the pressing plate 5 to pull The plate system 4 and the plate pulling system 4 pull apart multiple filter plates in the filter assembly 2 one by one. At this time, the low-speed motor 15 in the vibrating filter plate system drives the main transmission shaft 13 to rotate. The vibration bumps 12 are spaced apart and alternately arranged on the main transmission shaft 13 according to a certain angle. The main transmission shaft 13 drives the multiple vibration bumps 12 on it to rotate through the corresponding filter plate handles 16 sequentially. The plate is lifted, and after the vibrating block 12 turns an angle, the vibrating block is separated from the handle 16, and the filter plate falls freely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com