Translational rotor type compressor

A rotor-type compressor technology, applied in the field of compressors, can solve the problems of unreliable sealing between sliding vanes and rolling pistons, and achieve the effects of small friction and wear, elimination of voiding, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

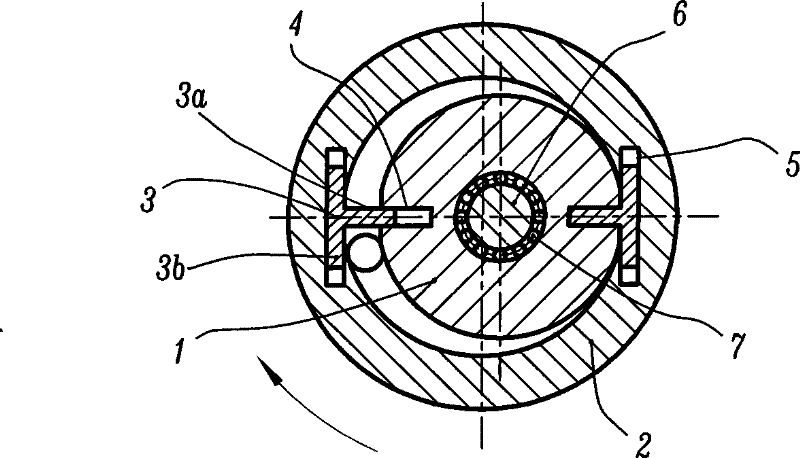

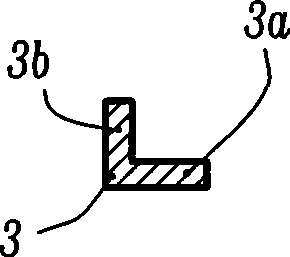

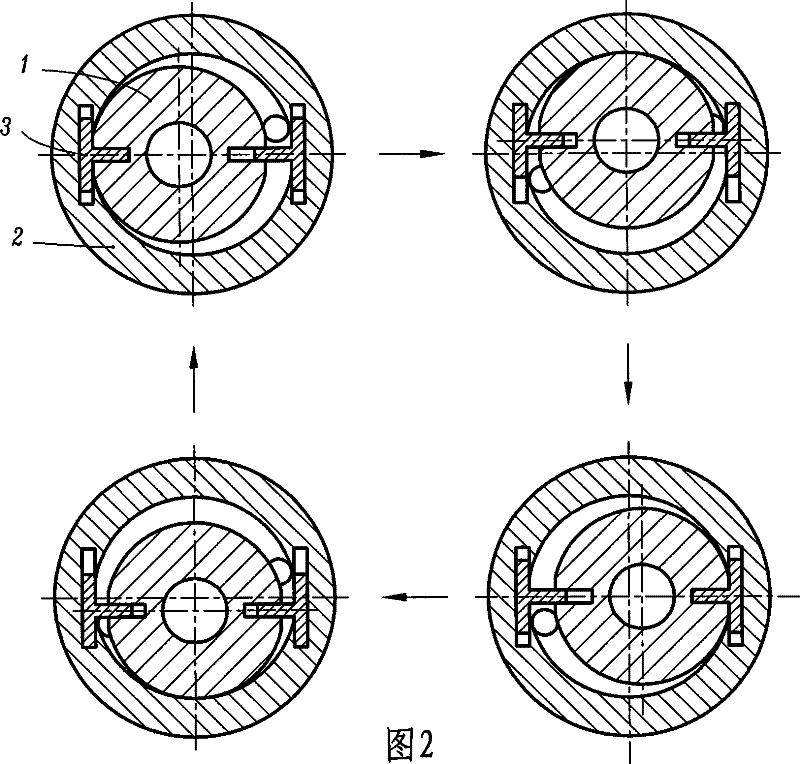

[0009] figure 1 and Fig. 2 respectively show a structural cross-sectional schematic diagram and a schematic working principle schematic diagram of a translational rotor compressor according to the present invention. The compressor includes a rotor 1, a cylinder body 2, and a sliding vane 3, as well as two front and rear end covers (not shown in the figure); the rotor 1 has a cylindrical outer surface, and the rotor 1 has a flat The rotor chute 4 (the best case is to open along the radial direction of the rotor 1); the cylinder block 2 has a round hole-shaped cylinder hole, and the cylinder block 2 is provided with a flat cylinder block chute 5; The slide 3 is a T-shaped structure (such as figure 1 and shown in Figure 2), it consists of two mutually perpendicular flat bodies: a radial flat body 3a and a tangential flat body 3b, wherein the radial flat body 3a is fitted in the rotor chute 4 and is slidably fitted with it, The tangential flat body 3b is fitted in the cylinder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com