Bicycle front fork shoulder cover production device capable of preventing middle from falling off

A technology for the production of equipment and bicycles, applied in the directions of transportation and packaging, winding strips, household components, etc., can solve problems such as affecting the winding step, uneven distribution of material, and reducing structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

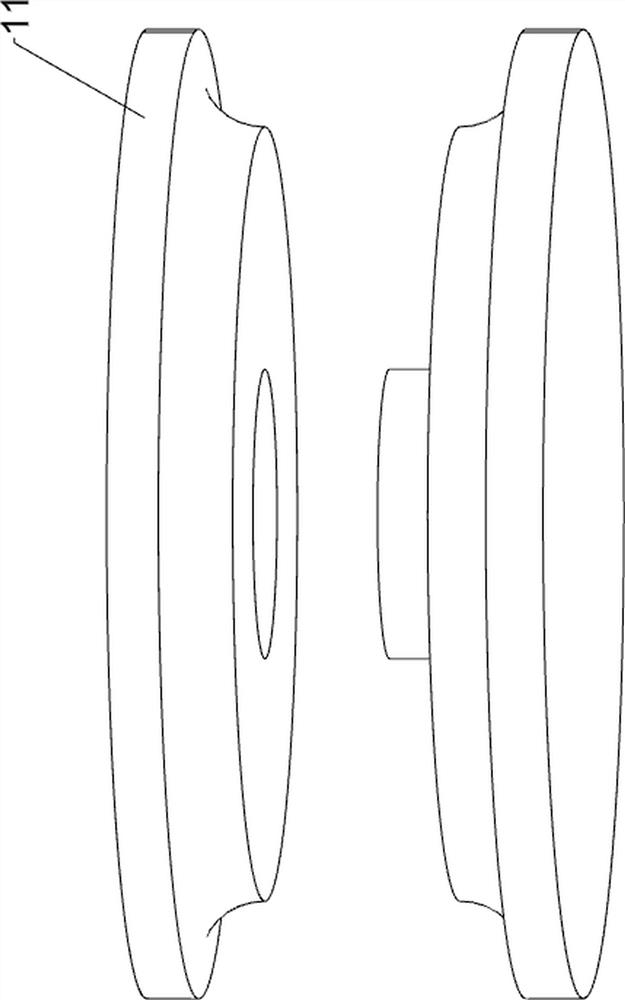

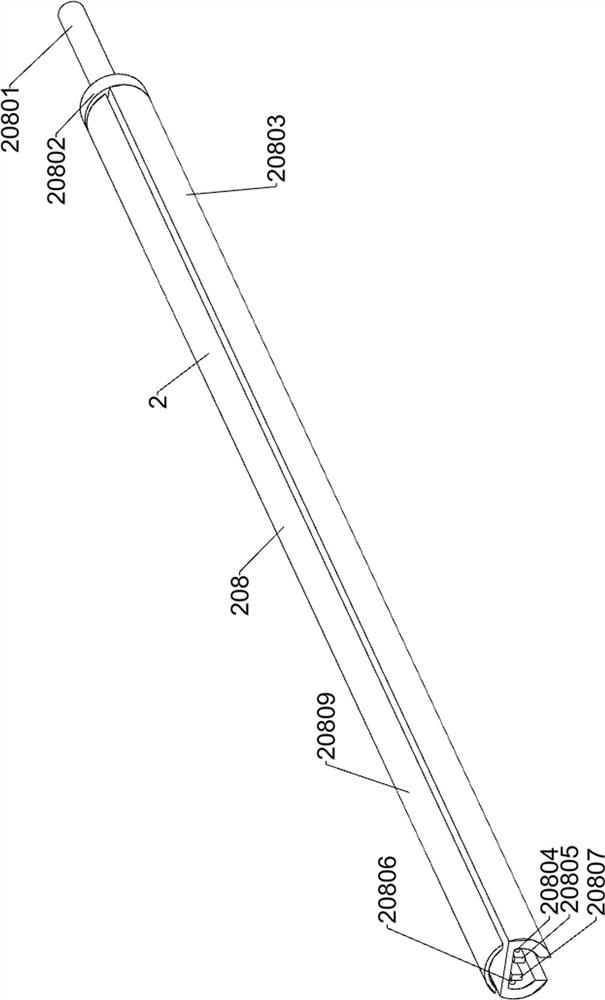

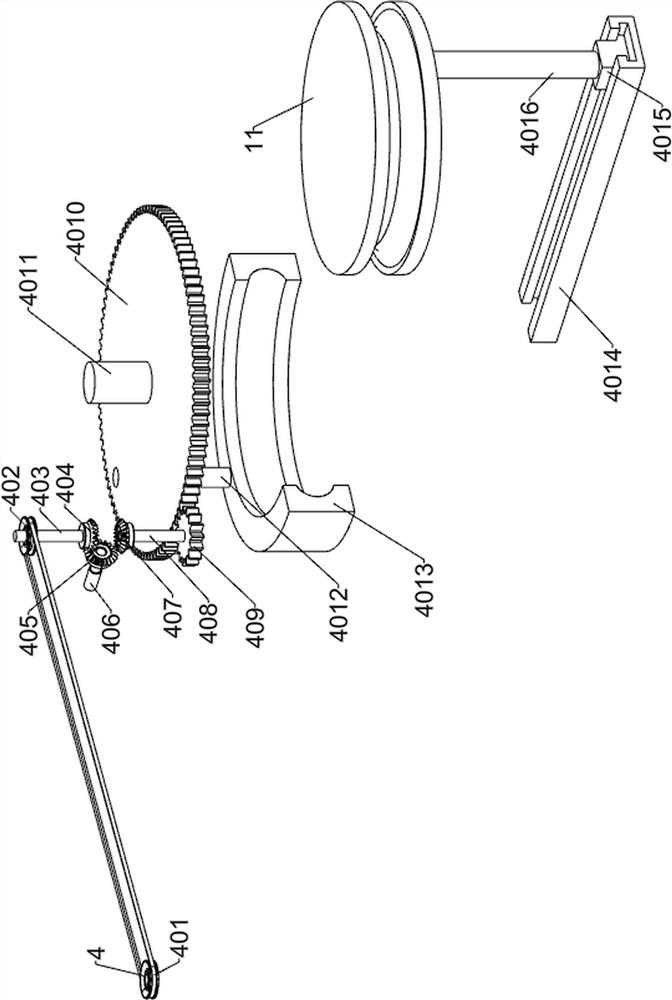

[0030] A bicycle front fork crown production device that can prevent the middle part from falling off, such as Figure 1-10 As shown, it includes a chassis 1, a winding assembly 2, a transport assembly 3, a coil assembly 4, a control panel 5, a first base 6, a second base 7, a first ring block 8, a first linkage block 9, The first electric push rod 10 and the first limit block 11; the bottom frame 1 is connected with the winding assembly 2; the bottom frame 1 is connected with the transport assembly 3; the bottom frame 1 is connected with the winding assembly 4; The control panel 5 is connected; the bottom frame 1 is connected with the first base 6; the bottom frame 1 is connected with the second base 7; the bottom frame 1 is connected with the first electric push rod 10; the winding assembly 2 and the winding assembly 4 connected; the transportation assembly 3 is connected with the coil assembly 4; the coil assembly 4 is connected with the first limit block 11; the first ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com