Method for one-step synthesizing N,N-diethyl-m-methyl benzamide in fixed bed

A technology of methyl benzamide and methyl benzoic acid diethylamine salt, which is applied in the field of chemical preparation, can solve the problems of discontinuous synthesis reaction, complex reaction route, and high comprehensive cost, and achieve uniform catalyst distribution and high yield , highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with specific examples, but the present invention is not limited to these disclosed embodiments, and the present invention will cover the range described in the patent book, and various modifications and equivalent changes of the scope of claims.

[0030] The technical process of embodiment 1-327 is: m-toluic acid and diethylamine are stirred and reacted in a 2000L stainless steel kettle under solvent system to generate m-toluic acid diethylamine salt complex, and then use 2J -x The plunger type metering pump continuously feeds the catalytic fixed bed, dehydrates at constant temperature and pressure to obtain a crude product, distills at atmospheric pressure to recover the solvent, and finally rectifies under reduced pressure to obtain pure N,N-diethyl-m-methylbenzamide Taste.

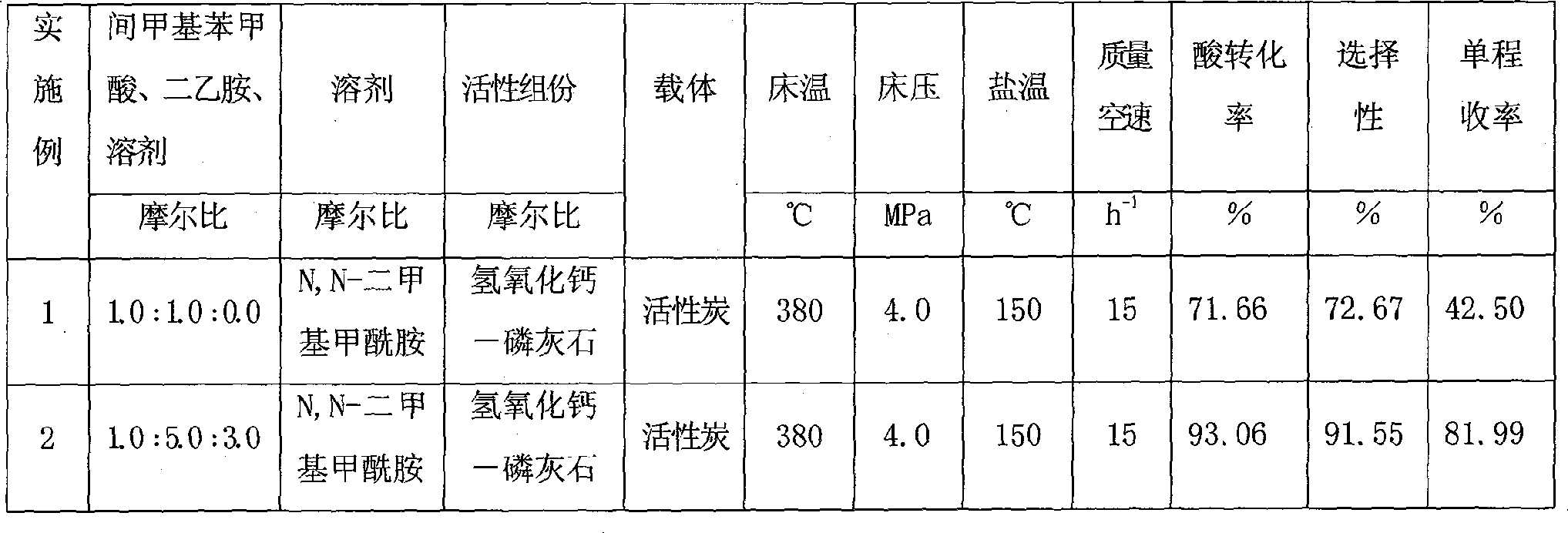

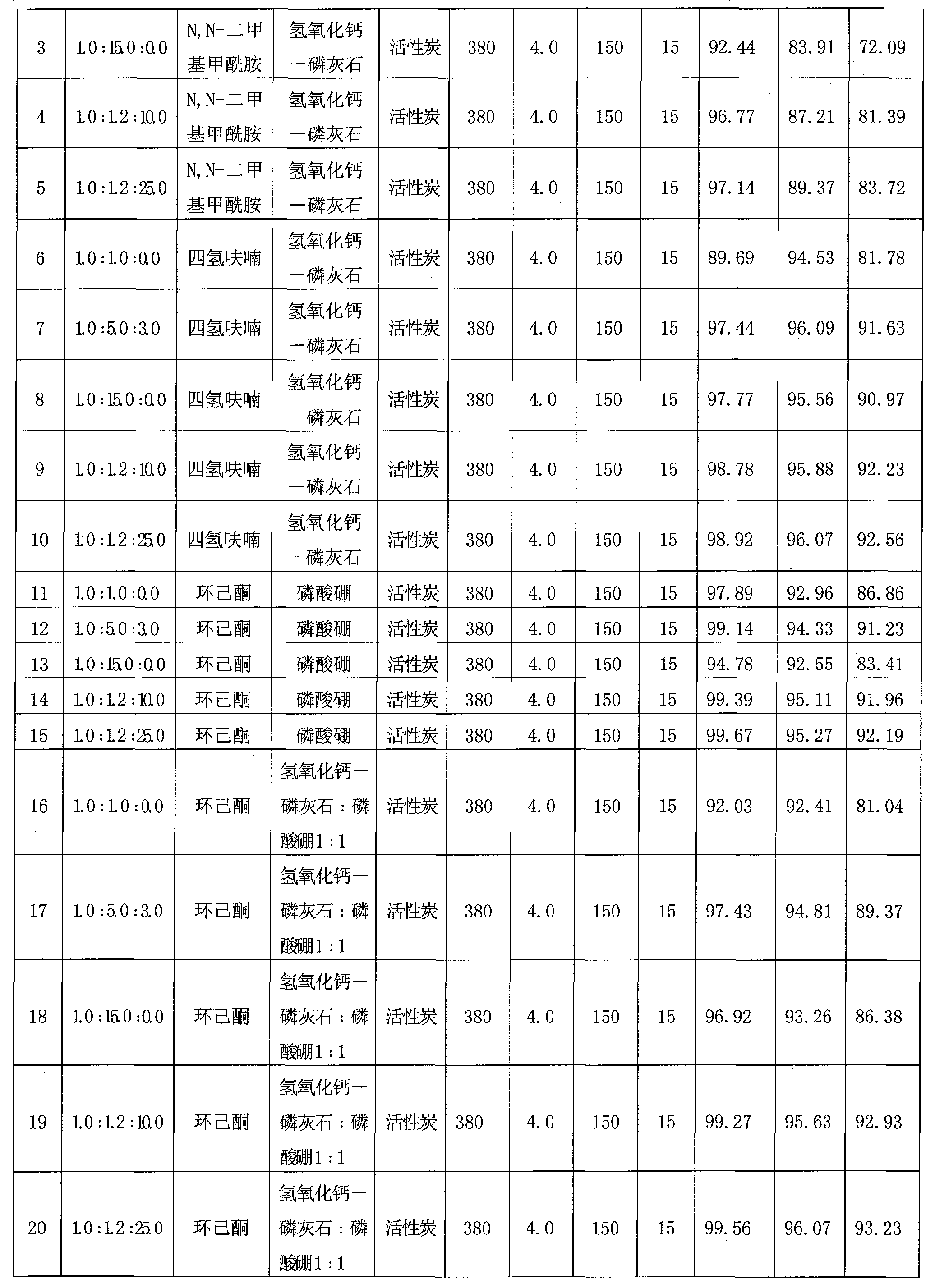

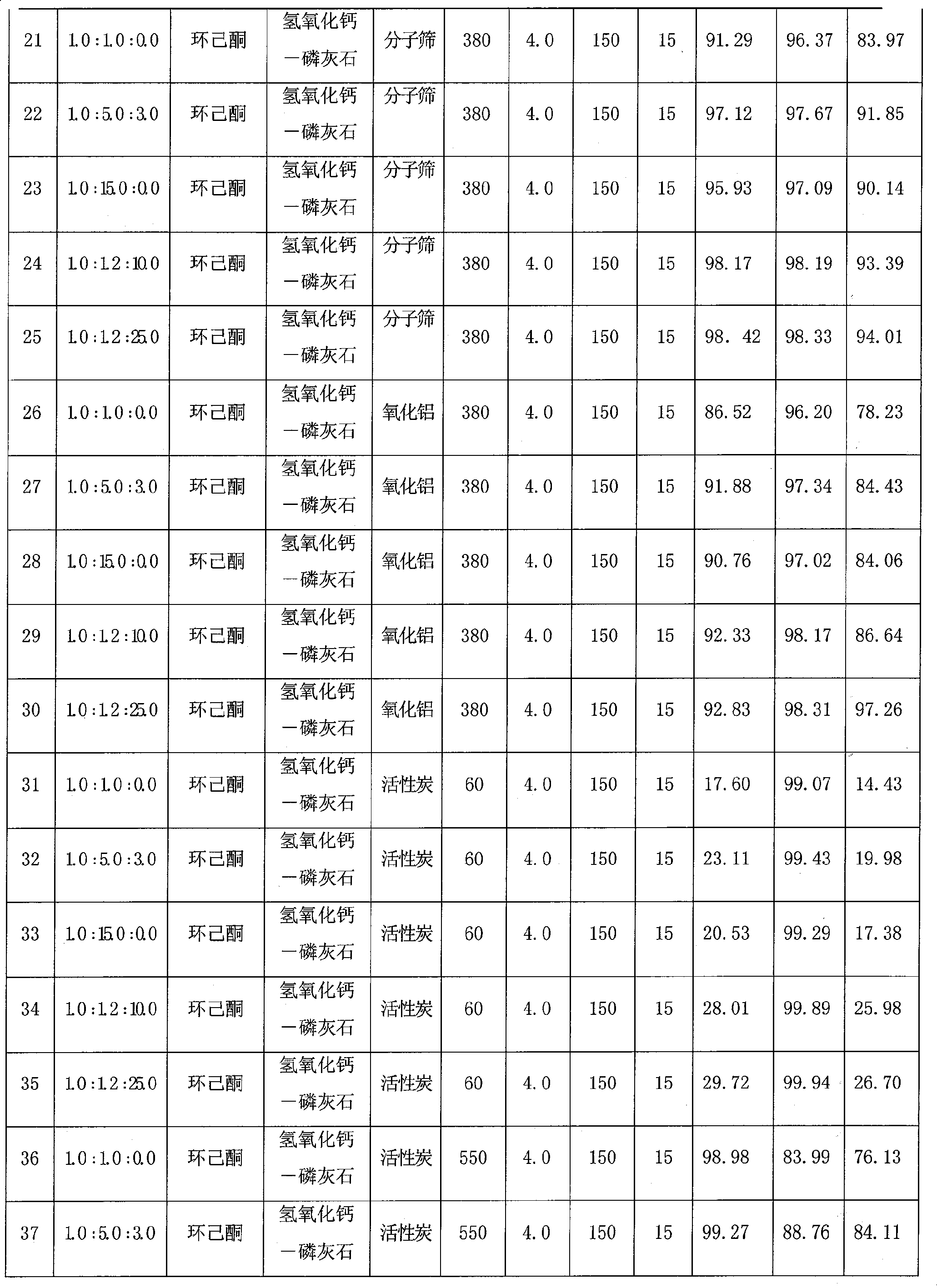

[0031] Embodiment 1-327 specific process conditions, m-toluic acid: diethylamine: solvent molar ratio, solvent type, catalyst ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com