Parallel move rotor type capacity-varied device

A rotor-type, translational technology, applied in the direction of rotary piston pumps, rotary piston machines, machines/engines, etc., can solve the problems of easy gas escape, unreliable sealing, gas leakage, etc., and achieve the elimination of void phenomenon, Effects of reducing leakage loss and eliminating leakage paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

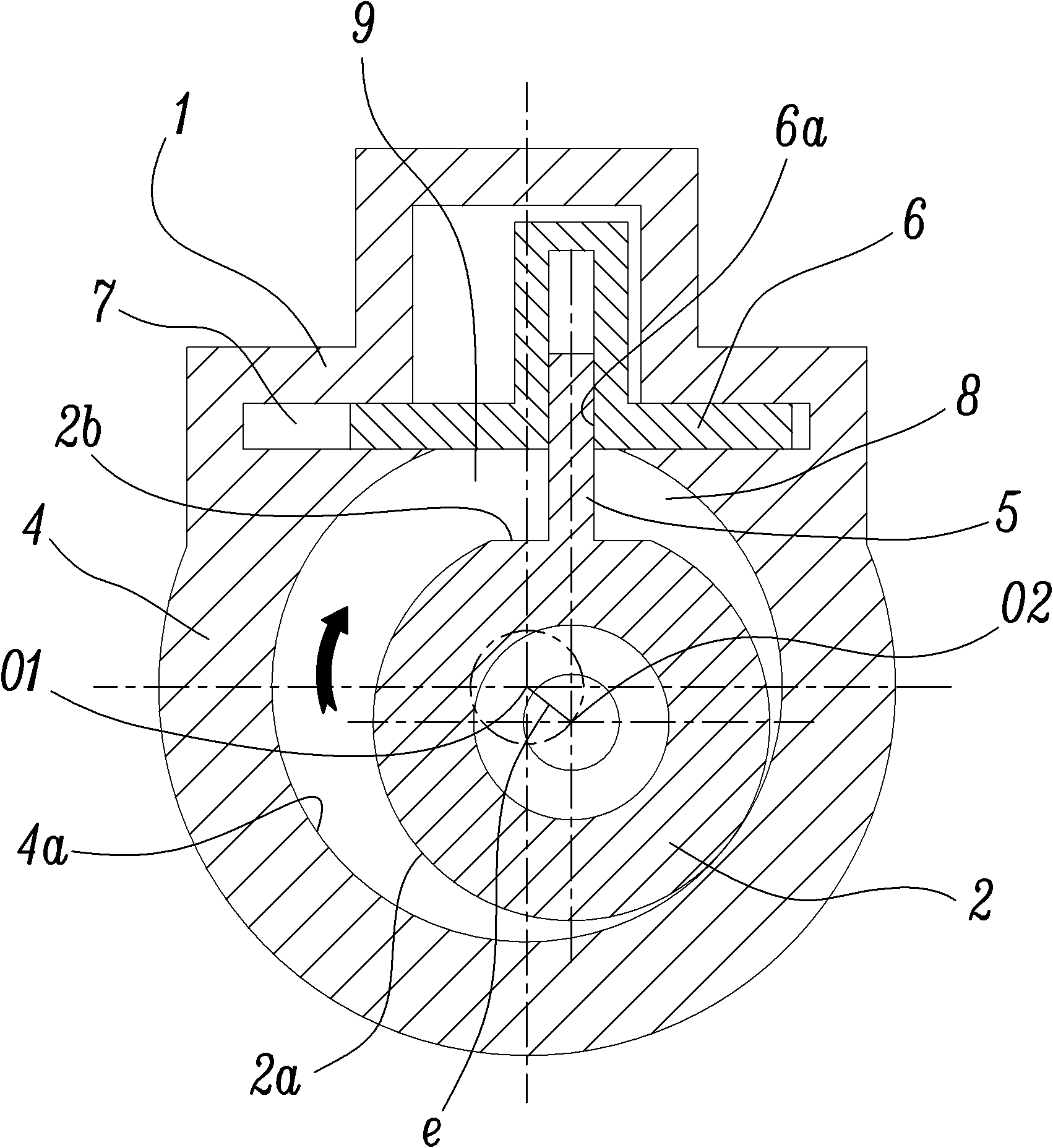

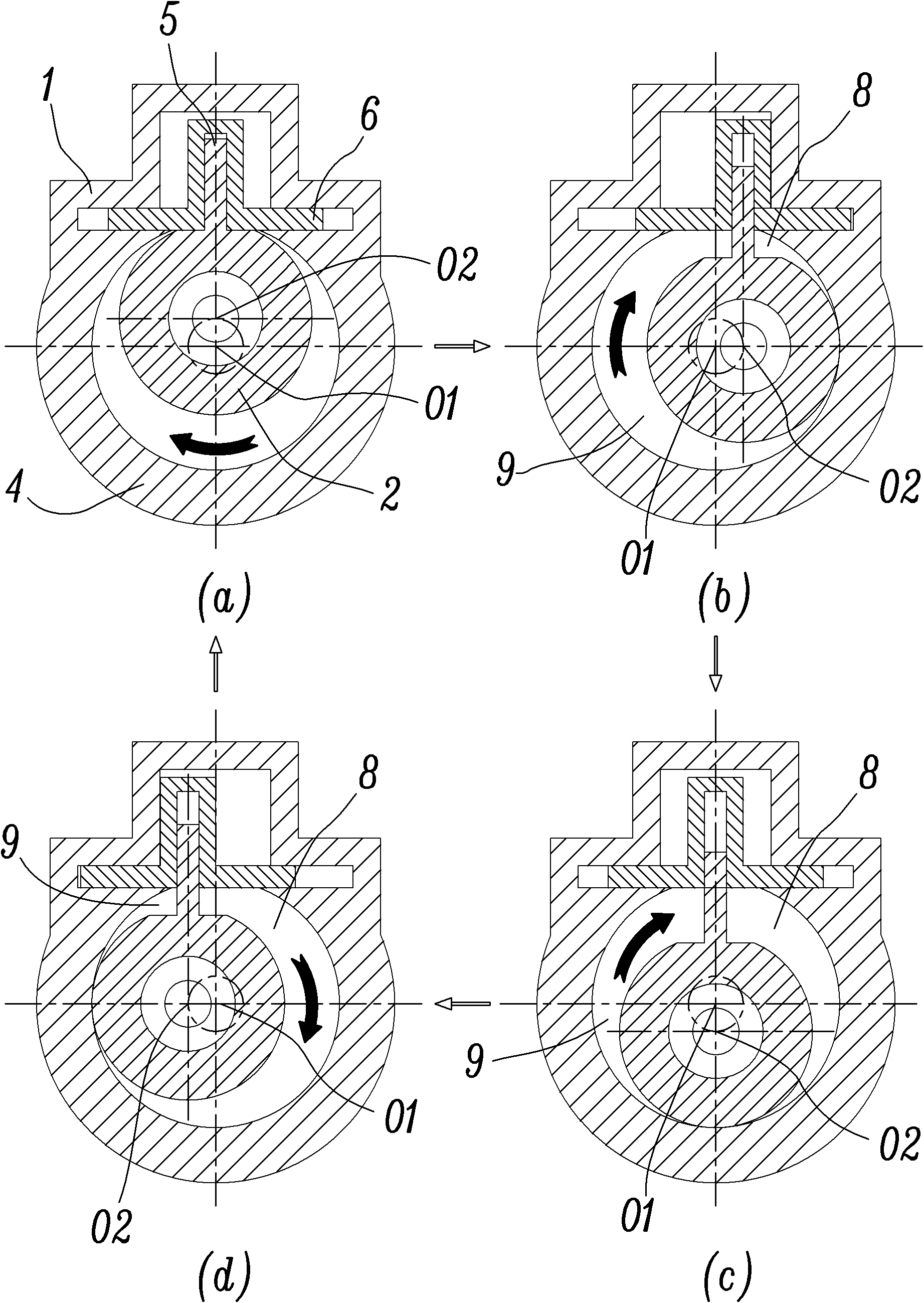

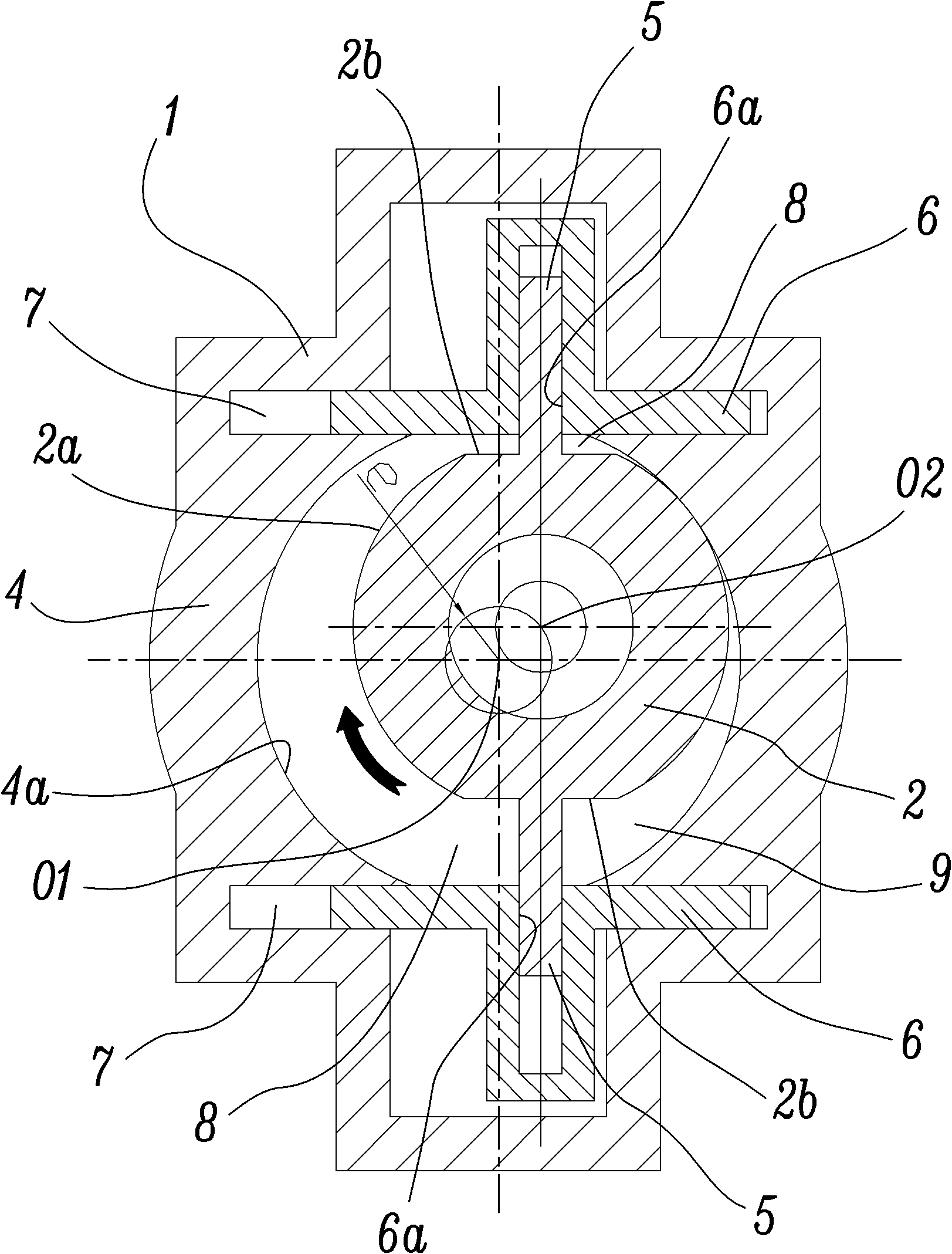

[0033] The present invention will be further described below with specific embodiment, see Figure 1-10 :

[0034] A translational rotor type variable capacity device, which includes a cylinder body 1, a rotor 2 and an end cover 3. The cylinder body 1 is provided with a cylinder 4. The cylinder 4 has an axial length and an arc-shaped inner hole surface. 4a, the rotor 2 has an arc-shaped cylindrical outer surface 2a, the rotor 2 is offset in the cylinder 4, the radius of the inner hole surface 4a of the cylinder 4 minus the radius of the cylindrical outer surface 2a of the rotor 2 is equal to the eccentricity e, the rotor The rotor axis O2 of 2 is parallel to the cylinder axis O1 of the cylinder 4 and rotates around the cylinder axis O1 with the eccentricity e as the radius. The end cover 3 is fitted on both sides of the cylinder 4 and fastened to the cylinder body 1 Above, the cylinder body 1 can be made in one piece or can be fastened or embedded by multiple parts; the featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com