Temperature and concentration gradient spiral baffle plate storage tank and application

A technology of spiral baffles and concentration gradients, which is applied to storage tanks and application fields of spiral baffles with temperature and concentration gradients, to achieve the effects of flexible space layout, prolonging the residence time, and realizing the requirements of concentration adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

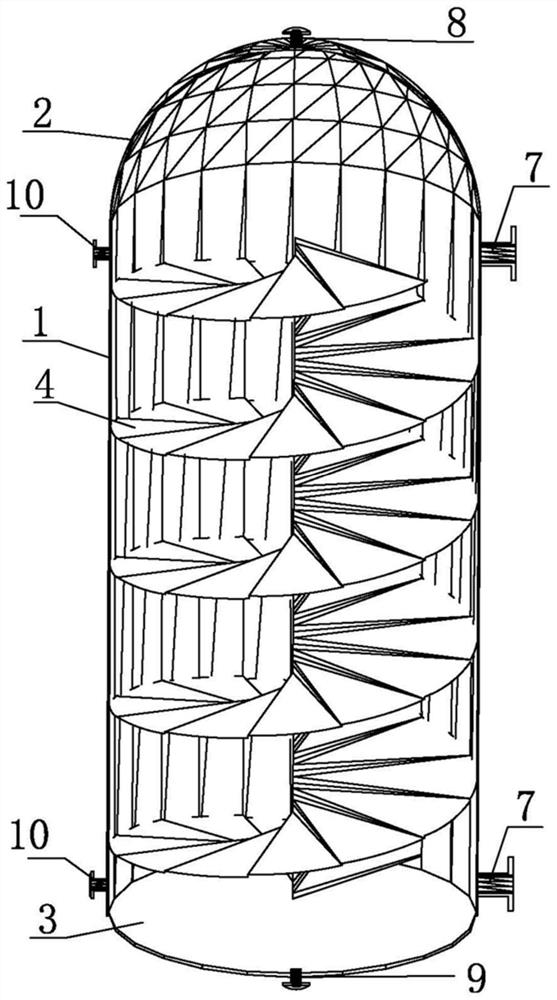

[0034] A temperature concentration gradient spiral baffle storage tank, such as figure 1 As shown, it includes a tank body, more than one helical baffle plate 4 that is evenly distributed in the vertical direction of the tank body and has closed edges, an inlet and outlet pipe group and an instrument interface group.

[0035] The tank body includes a cylindrical cylinder body 1, an upper head 2 and a lower head 3; the upper head 1 and the lower head 2 are respectively welded and connected to the upper and lower end surfaces of the cylinder 1; The upper head 2 is an elliptical hemispherical head; the lower head 3 is a flat head under low pressure conditions, and an elliptical hemispherical head under high pressure conditions.

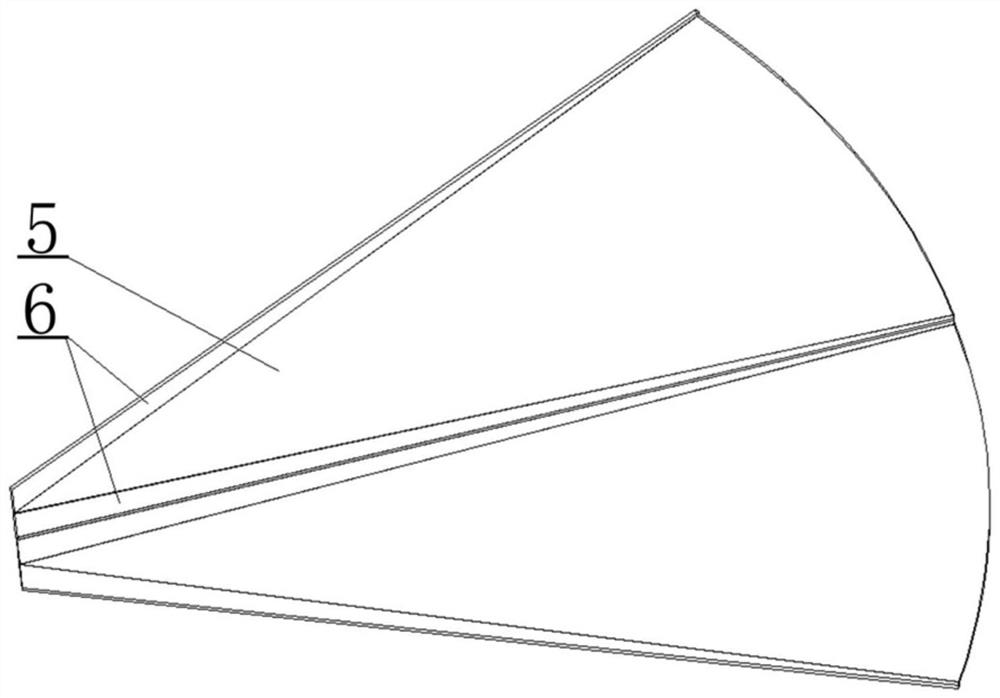

[0036] Such as figure 2 As shown, the spiral baffle 4 is divided into a fan-shaped area 5 and two triangular areas 6, wherein the fan-shaped area 5 is determined by the inner diameter of the cylinder 1, the inclination angle and the fraction of the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com