Trust bearing device

A thrust bearing, bearing surface technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as uneven wear and uneven bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

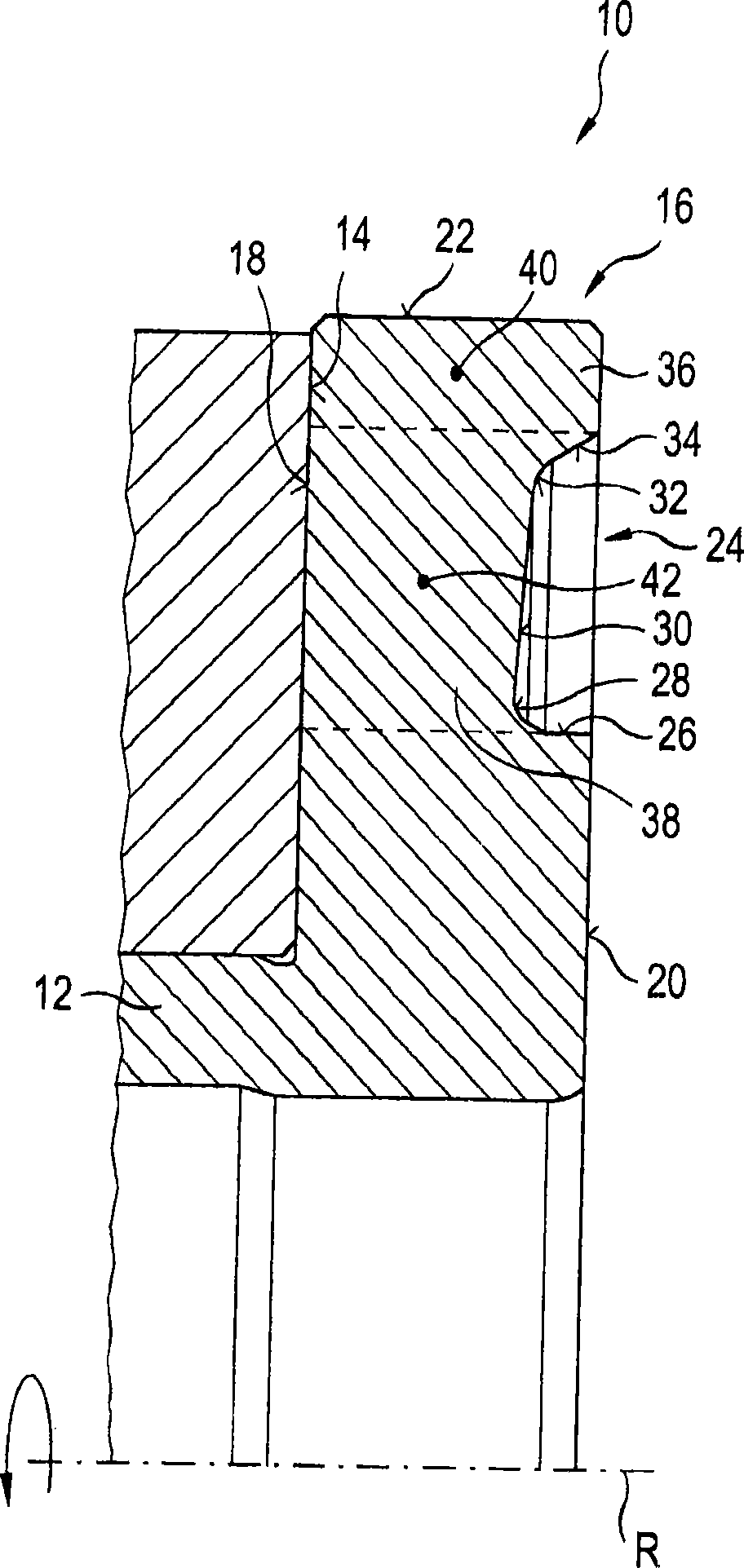

[0021] exist figure 1 Shown in is the upper half of a longitudinal section along the axis of rotation R for axially supporting a shaft 12 according to the invention. Thrust bearing arrangement 10 has a stationary bearing surface 14 arranged in the housing, which lies in a plane extending at right angles to axis R of rotation.

[0022] The shaft 12 is provided at its free end with a radially outwardly projecting thrust bearing shoulder 16 . Thrust bearing shoulder 16 has a rectangular basic shape in cross section and merges into the peripheral surface of shaft 12 with the formation of free cuts. The thrust bearing shoulder 16 has a bearing surface 18 which also extends at right angles to the axis of rotation R, by means of which the bearing shoulder 16 is pretensioned on the bearing surface 14 for axial support.

[0023] Thrust bearing shoulder 16 is provided with a groove 24 on its rear side 20 facing away from bearing surface 18 at a distance from its peripheral surface 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com