Motor axle and method for manufacturing a cross member of a motor axle

A technology for motor vehicles and axles, which is applied in the directions of axles, cantilevers mounted on pivots, wheels, etc. It can solve the problems of compound steering axle track or camber stiffness and rolling stiffness limitations, and achieve the effect of eliminating welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

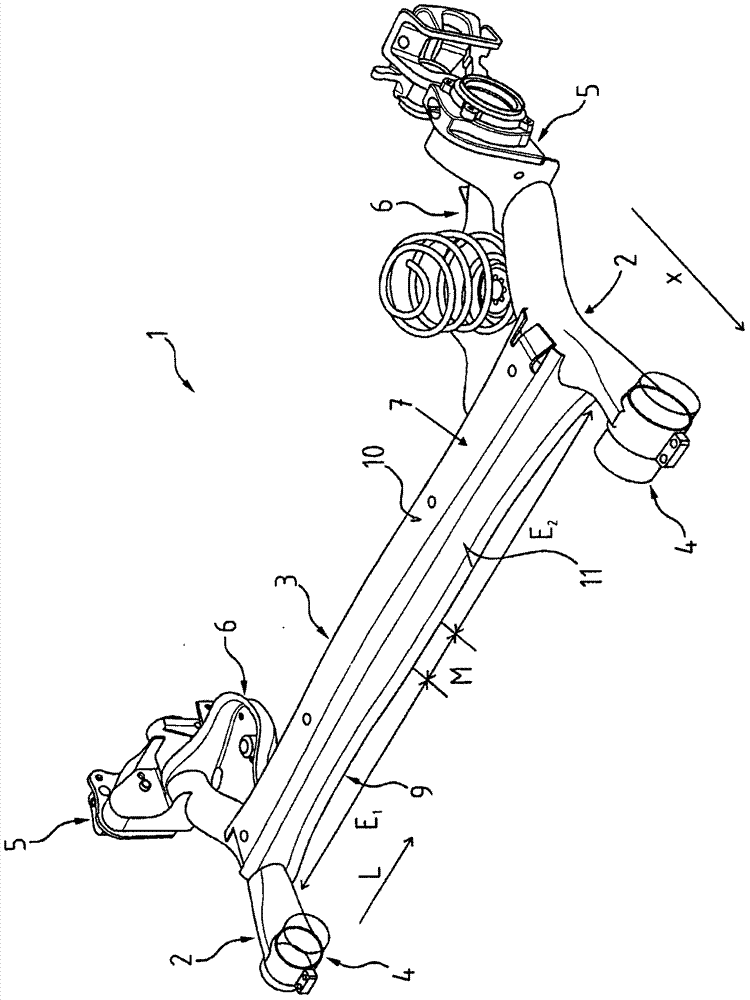

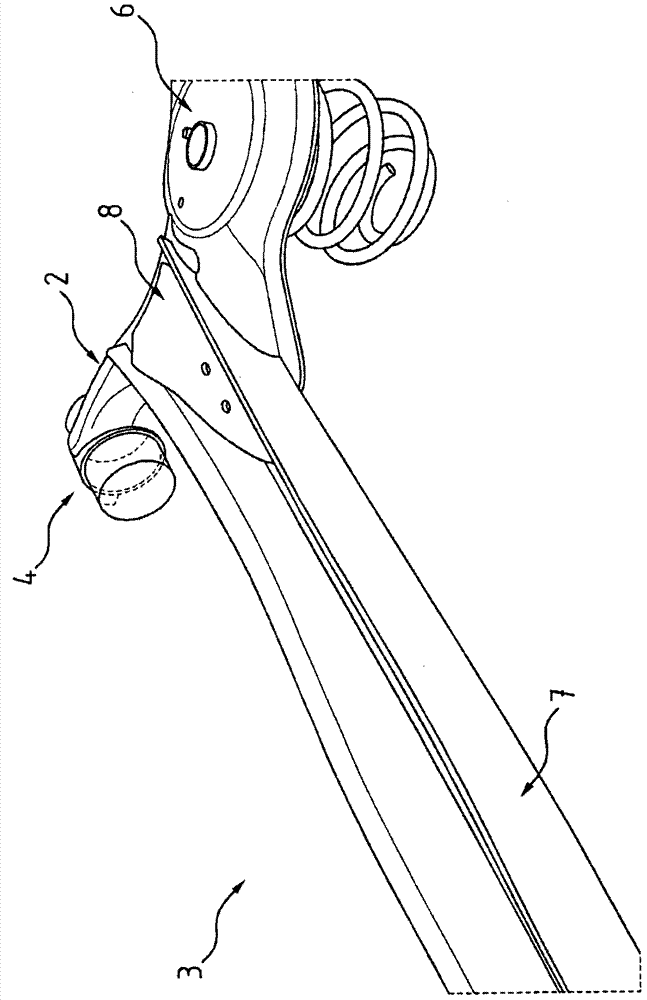

[0052] figure 1 A motor vehicle axle 1 according to the invention is shown. The motor axle 1 comprises two trailing arms 2 and a cross member 3 connecting the two trailing arms. The trailing rods 2 each have a connecting portion 4 connecting the trailing rods 2 to the vehicle body. In addition, the trailing arm 2 is provided with a connection 5 to the wheel carrier.

[0053] Furthermore, the motor axle 1 has a spring seat 6 with which a coil spring can be accommodated.

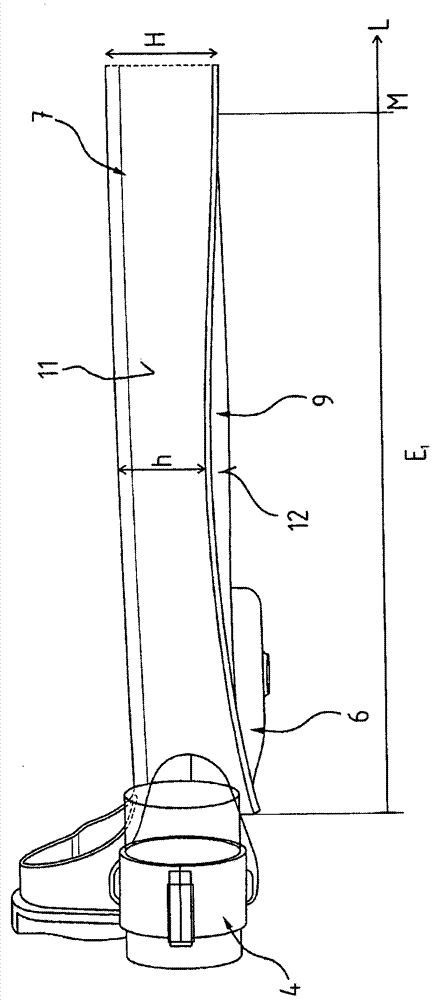

[0054] The beam 3 comprises an open profile 7 with a U-shaped cross-section. The profile 7 has a web 10 and two legs 11 , 12 bent from this web on the longitudinal sides. The characteristic here is that the side 11 on the front side of the vehicle (that is to say the side pointing in the direction of travel X) is located at the end section E of the profile 7 . 1 ,E 2 The inside has a reduced height H relative to the middle section M of the profile 7 .

[0055] Along the length L of the beam 3, the end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com