AC electricity driving method for LED and working voltage thereof

A technology driven by light-emitting diodes and alternating current, applied in the direction of electric lamp circuit layout, light source, electric light source, etc., can solve the problems of half-cycle energy waste, low total impedance value, etc., and achieve the effect of preventing high temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

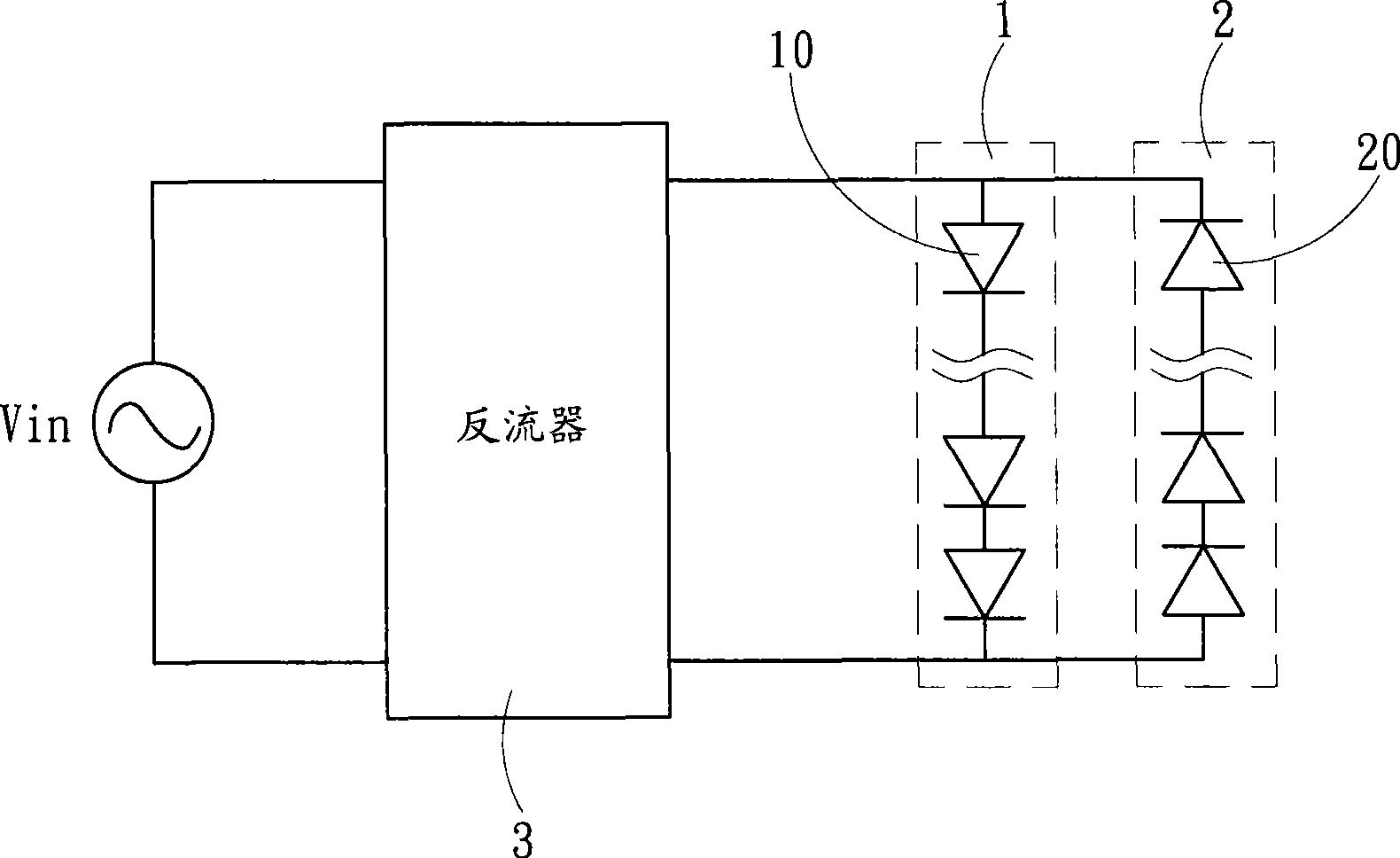

[0020] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

[0021] see image 3 Shown is a schematic circuit diagram of a preferred embodiment of the present invention. The LED alternating current driving method of the present invention comprises the following steps:

[0022] Steps to obtain AC power: Connect external power Vin to obtain AC sine wave signal S1 with positive and negative half-cycle waveforms (see Figure 4 As shown), the following assumes that the alternating current is 110 volts, 60 Hz frequency, that is, the lowest voltage value is 0 volts, and the highest voltage value is about 155 volts.

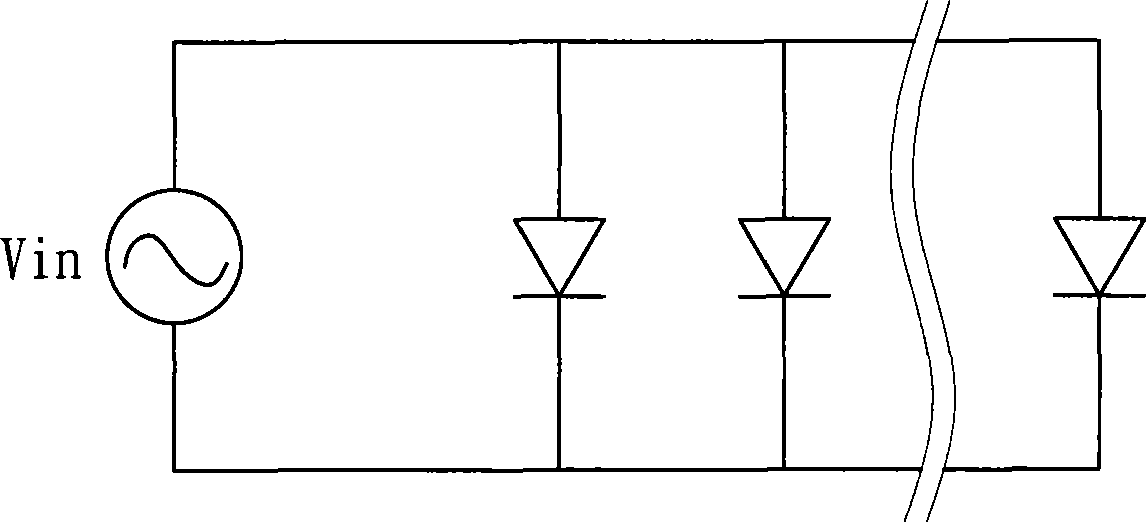

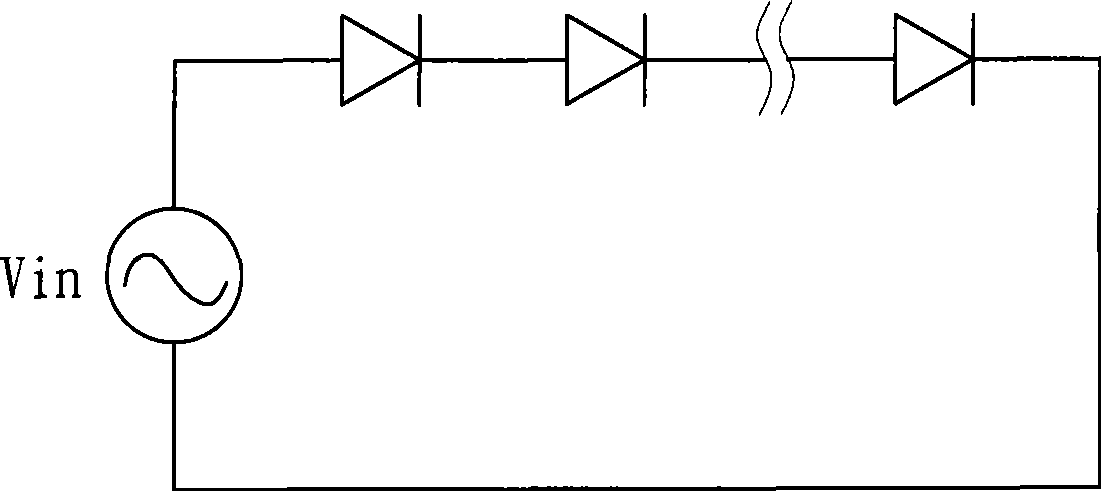

[0023] Light-emitting diode group setting step: it sets at least two first and second light-emitting diode groups 1 and 2 with opposite conduction directions and connected in parallel. In a preferred embodiment, each light-emitting diode group 1 and 2 is set to a plurality LEDs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com