Filling and disinfecting method for sodium bicarbonate injection in glass transfusion bottle

A technology of sodium bicarbonate and sterilization method, which is applied in the field of bottle opening loosening and bottle bursting during the sterilization process of glass infusion bottled sodium bicarbonate injection, and can solve the problem of increasing the incidence of clinical adverse reactions, increasing production costs, and product failure. Potential safety hazards and other issues, to achieve the effect of solving the phenomenon of bottle loosening and bottle bursting, controlling production costs, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The filling and sterilizing method of sodium bicarbonate injection in glass infusion bottles comprises the following steps:

[0009] 1. Fill the qualified 5% concentration sodium bicarbonate injection according to the production prescription into clean glass infusion bottles. The filling volume of each bottle is in ml or L. By volume, the amount of sodium bicarbonate injection is Volume: volume of glass infusion bottle=1:1.25~1:2.40;

[0010] 2. Plug the gland according to the conventional production process;

[0011] 3. Sterilize at 115°C for 30 minutes.

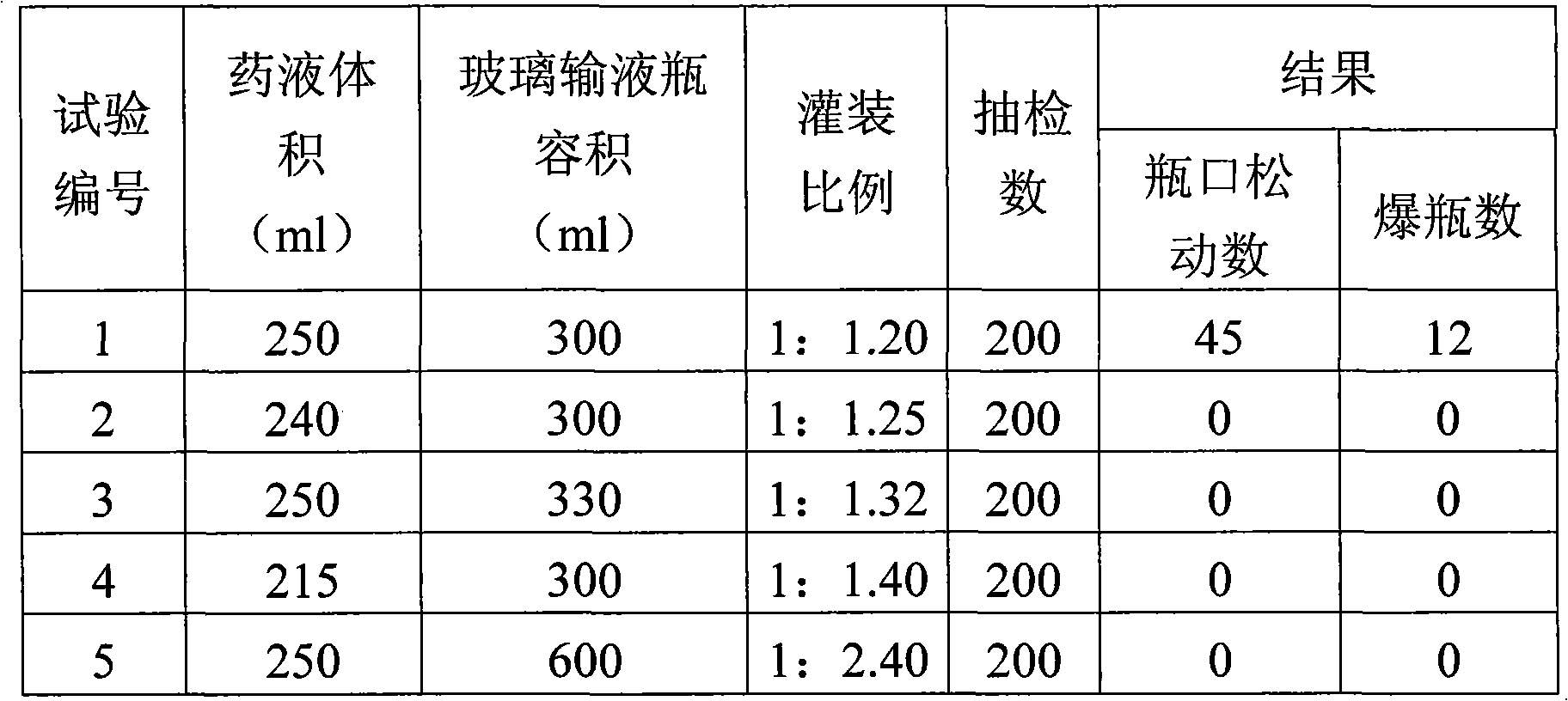

[0012] Now, the effects of the technical solutions described in the present invention are compared with several groups of specific embodiments.

[0013]

[0014] What numbering 1,2,4 embodiment adopts is the glass infusion bottle that the capacity that national standard 250ml specification sodium bicarbonate injection adopts is 300ml, and what numbering 5 embodiment adopts is that national standard 500ml specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com