On-line energy forecasting system and method based on product ARIMA model

A predictive system and energy technology, applied in the direction of comprehensive factory control, technical management, comprehensive factory control, etc., can solve the problems of restricting wide application, exponential growth of data trends, unusable for prediction, etc., and achieve the effect of simple external application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

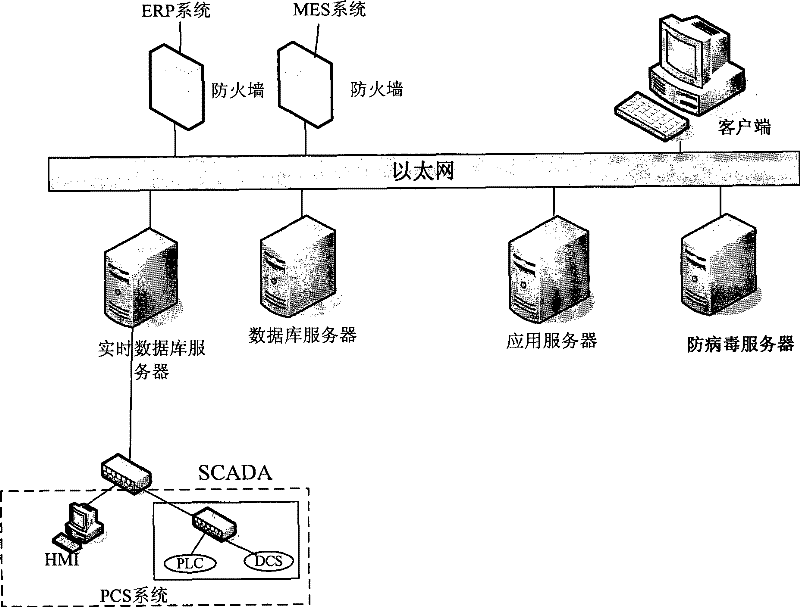

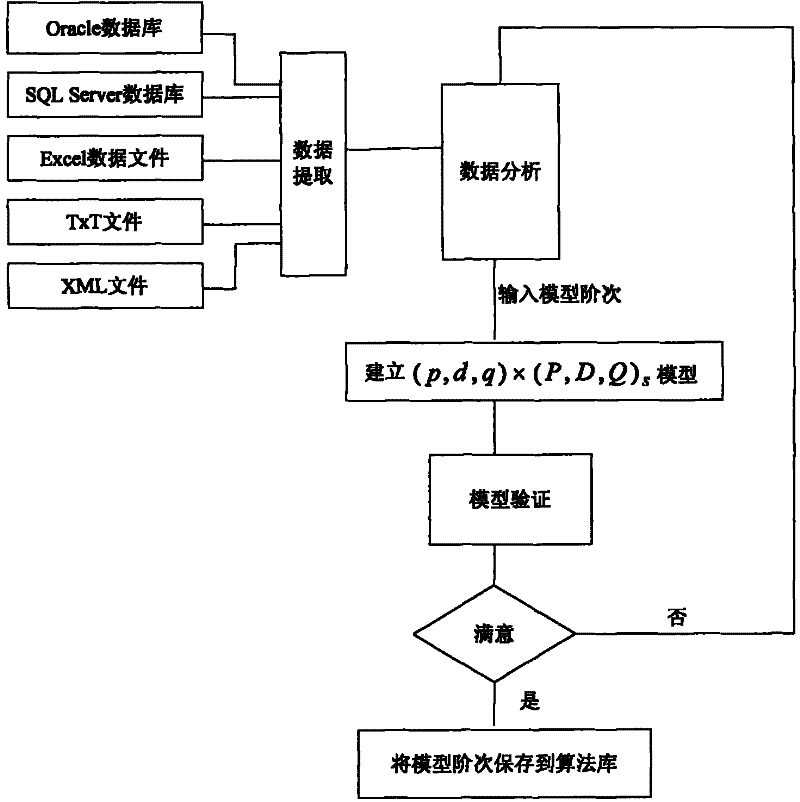

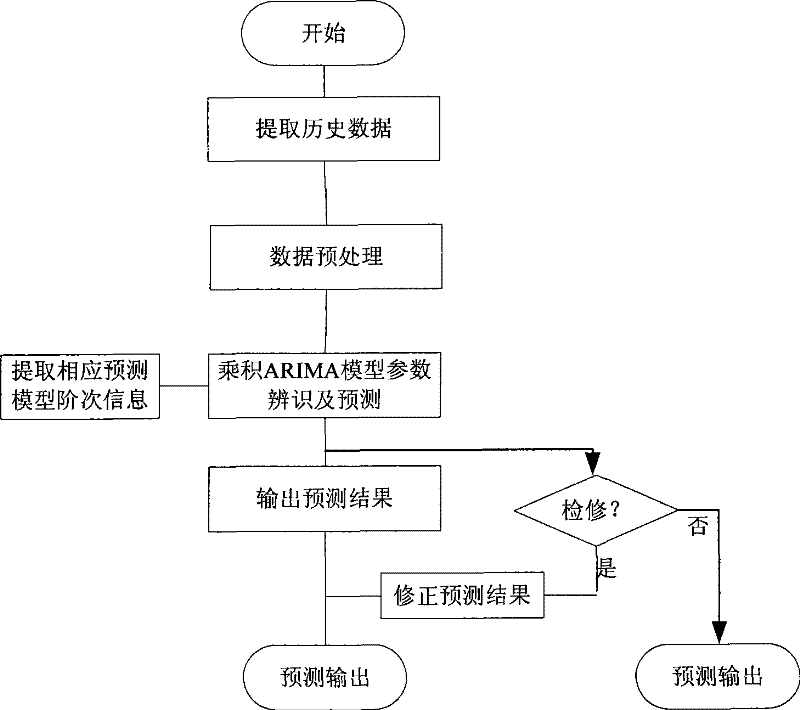

[0034] Figure 1 ~ Figure 4 It is a specific embodiment of the present invention.

[0035] figure 1 It is a system structure diagram, mainly including the underlying data acquisition system, real-time database server, database server, application server, anti-virus server, and client. Among them, the data acquisition system is mainly responsible for data acquisition and on-site monitoring; the database server and real-time data server provide data support for the realization of the prediction function; the application server mainly runs the prediction module; the client mainly provides the function of human interaction and displays the prediction results in a graphical way .

[0036] figure 2 Configure the flowchart for the parameters of the product ARIMA model. Extract the energy data of the forecast project from the data source, and after data analysis, initially determine the model order, establish the product ARIMA model according to the determined model order, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com