Motor speed control circuit

A speed control, speed voltage technology, applied in the control system, motor control, electrical components, etc., can solve the problems of motor speed increase, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

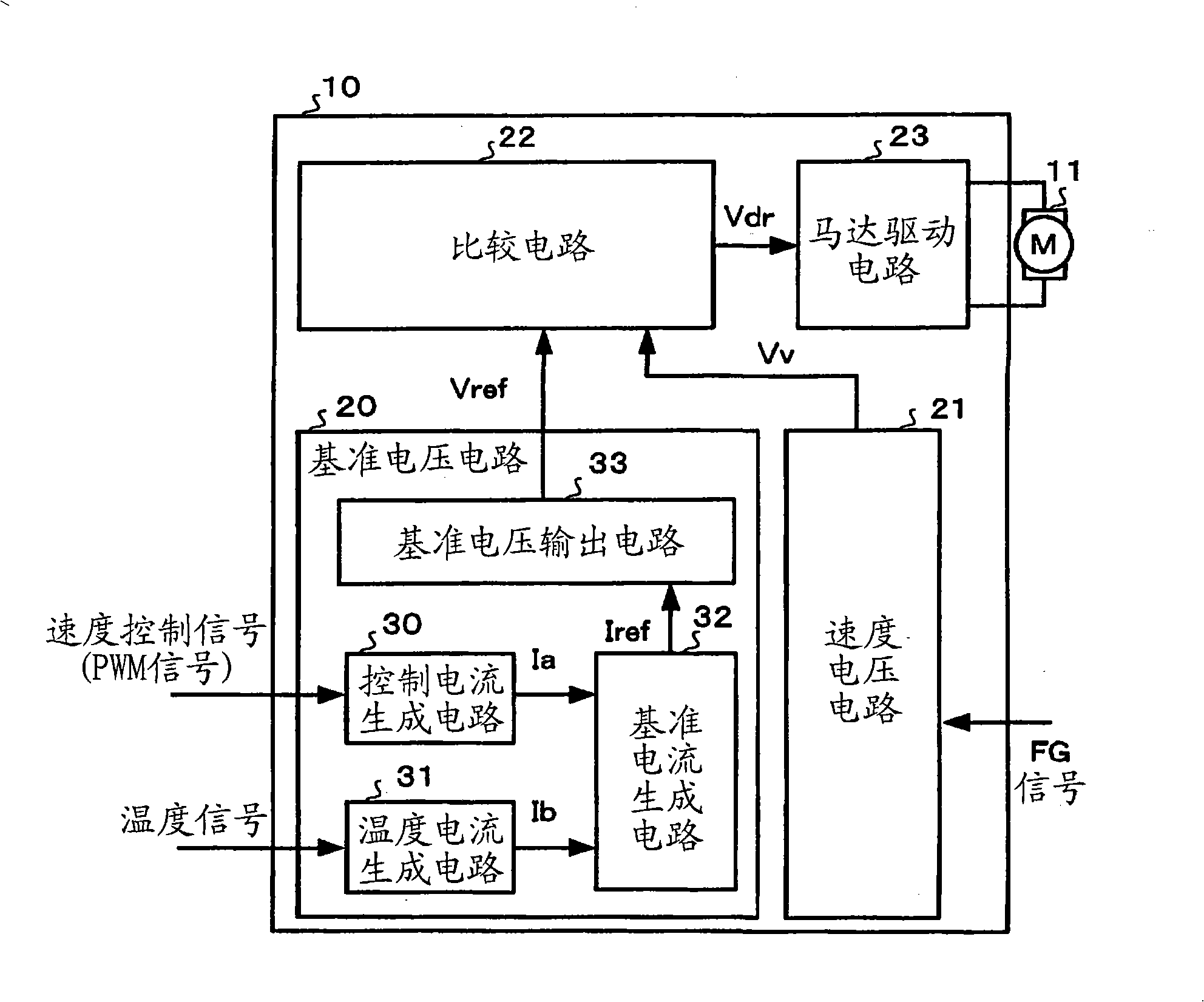

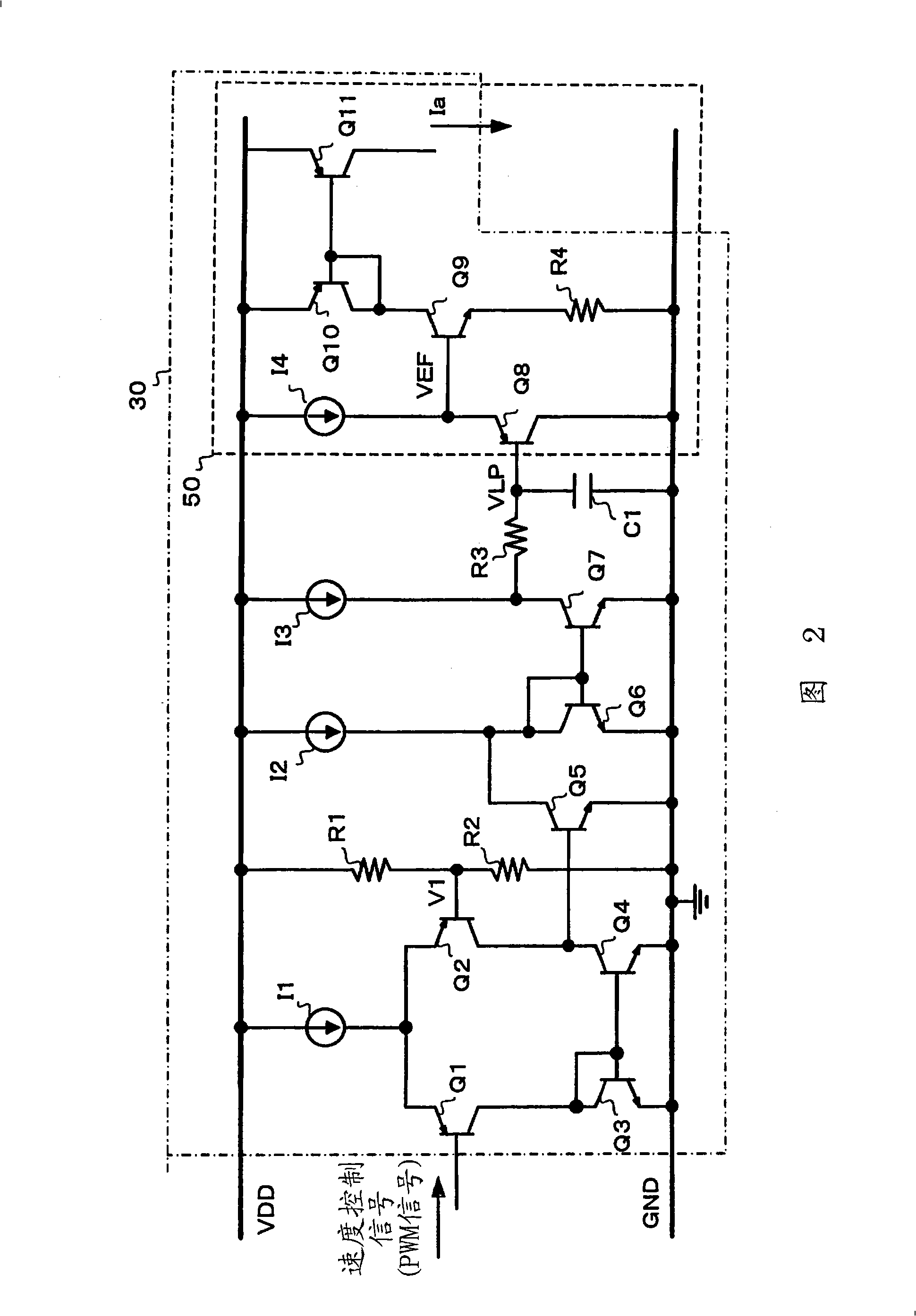

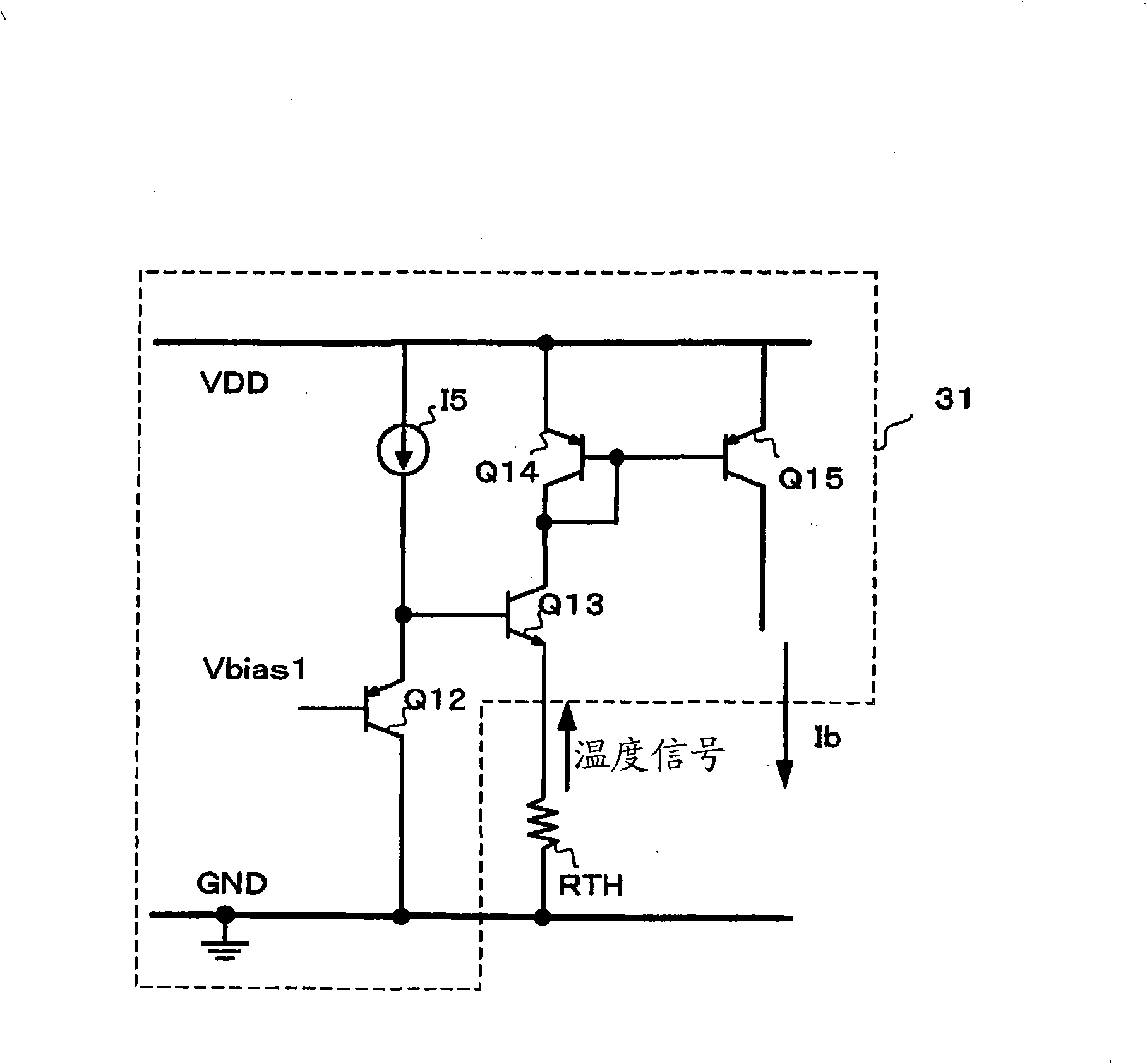

[0032] figure 1 It is a figure which shows the structure of the motor speed control circuit 10 which is 1st Embodiment of this invention. FIG. 2 is a diagram illustrating an embodiment of the control current generation circuit 30 . image 3 It is a diagram showing an embodiment of the temperature current generating circuit 31 to which the thermistor RTH is connected. FIG. 4 is a diagram illustrating an embodiment of the reference current generating circuit 32 . Figure 5 It is a diagram showing an embodiment of the reference voltage output circuit 33 . FIG. 6 is a diagram showing an embodiment of the speed voltage circuit 21 . FIG. 7 is a diagram showing one embodiment of the comparison circuit 22 . refer to figure 1 The motor speed control circuit 10 of the first embodiment will be described with reference to FIG. 7 .

[0033] The motor speed control circuit 10 controls the speed of the motor 11 according to the speed control signal corresponding to the target rotatio...

no. 2 approach

[0070] Figure 10 It is a figure which shows the structure of the motor speed control circuit 100 which is 2nd Embodiment of this invention. FIG. 11 is a diagram illustrating an embodiment of the reference voltage circuit 200 . Figure 12 It is a diagram showing an embodiment of the temperature current generating circuit 300 to which the thermistor RTH is connected. FIG. 13 is a diagram showing an embodiment of the speed voltage output circuit 310 . refer to Figure 10 ~ Figure 1 3. The motor speed control circuit 100 of the second embodiment will be described.

[0071] The motor speed control circuit 100 is a circuit for controlling the rotation speed of the motor 11 based on a speed control signal corresponding to the target rotation speed of the motor 11, a temperature signal corresponding to the temperature, and a speed signal corresponding to the actual rotation speed of the motor 11 input from the microcomputer. , consists of a reference voltage circuit 200 , a speed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap