Method and apparatus for the detection of cracks in the teeth of generator rotors

A technology for generator rotors and rotor teeth, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

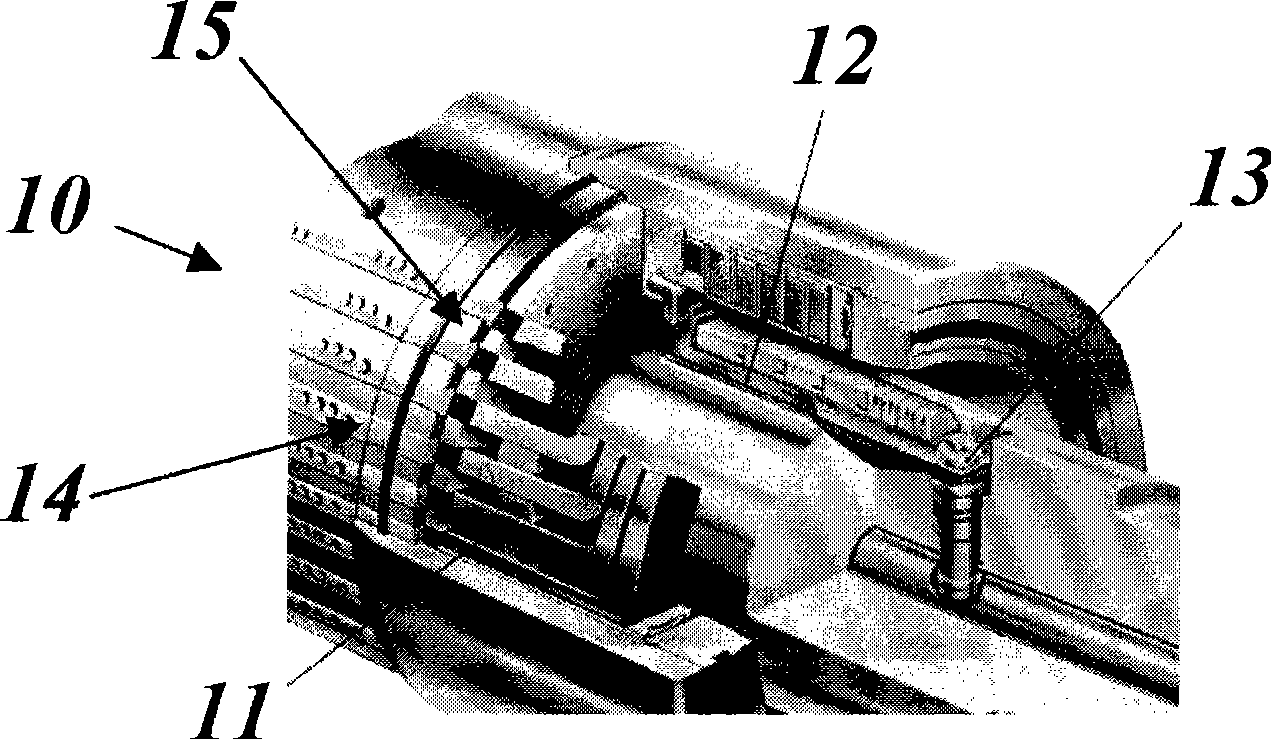

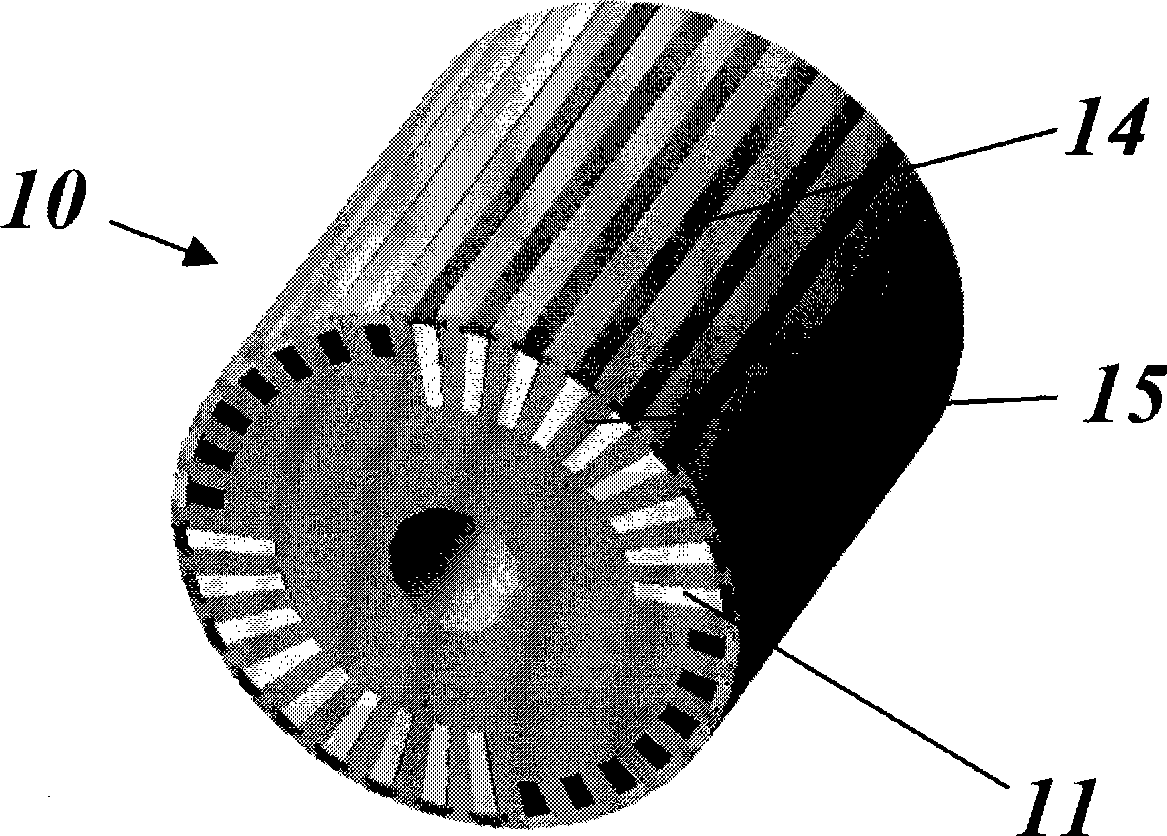

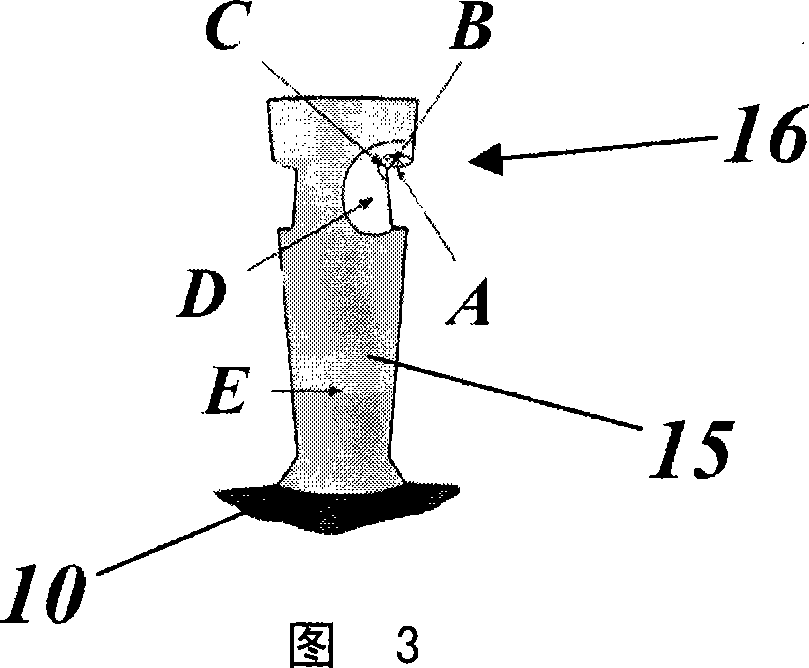

[0036] The present invention describes a novel ultrasound method which utilizes a simpler and more compact ultrasound pulse echo technique than the phased array method of the prior art (EP-A1-1777513).

[0037] Not only is the new method capable of detecting wear cracks inside the assembled rotor, it has also proven to be compact enough for field measurements, i.e. it fits in the limited space of the air gap between the rotor and stator, thus allowing condition assessment of the generator rotor, even There is no need to remove the rotor from the stator.

[0038] The new method and device can be easily applied to existing deployment robots and institutions.

[0039] The new method and device are especially capable of preventing catastrophic failures due to cracks caused by aging.

[0040] The proposed system for inspecting generator rotors consists of an array of pulse-echo ultrasonic transducers (see Figure 5 18) in , which provides a range of active elements, with special ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com