Composite slope guarding hydraulic support and use thereof

A technology of hydraulic support and support, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of low reliability, low efficiency, complex structure, etc., and achieve high reliability, convenient use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

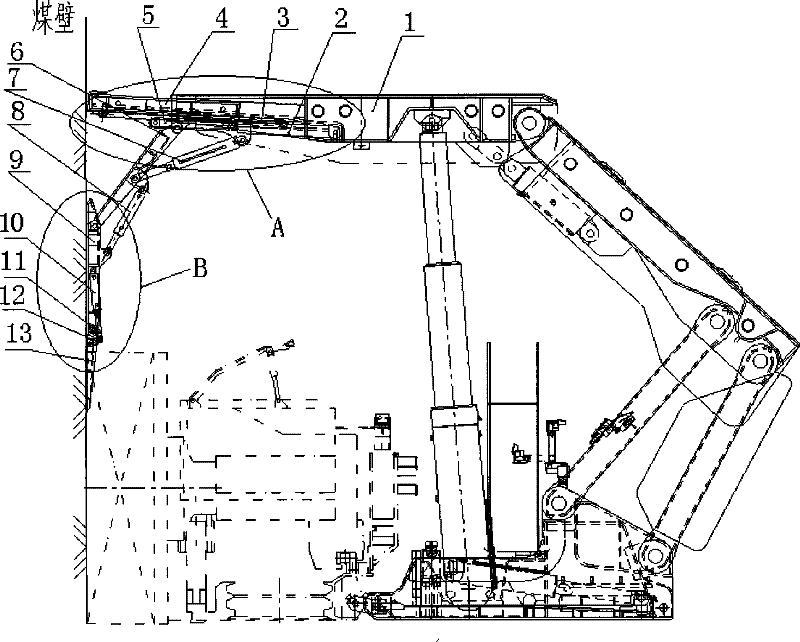

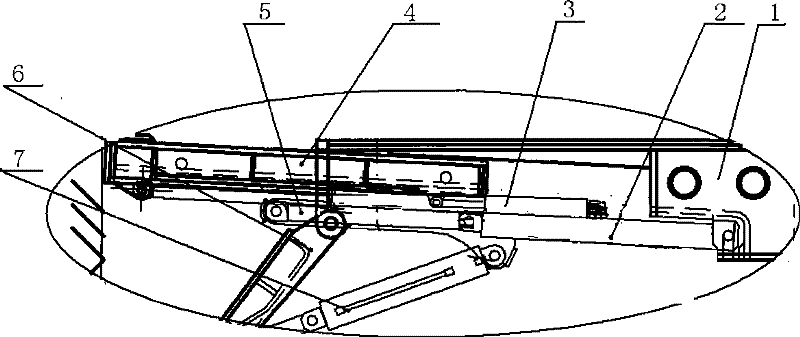

[0015] Composite side protection hydraulic support of the present invention, its preferred embodiment is as follows figure 1 As shown, the top beam 1 is included, and the front portion of the top beam is provided with a side protection mechanism and a telescopic beam 4 independent of each other.

[0016] Wherein, the telescopic beam 4 is slidably connected with the top beam 1, and a telescopic jack 3 is arranged between the telescopic beam 4 and the top beam 1, which is used to drive the telescopic beam 4 to expand and contract along the top beam 1, so as to realize the roof protection function of the telescopic beam 4.

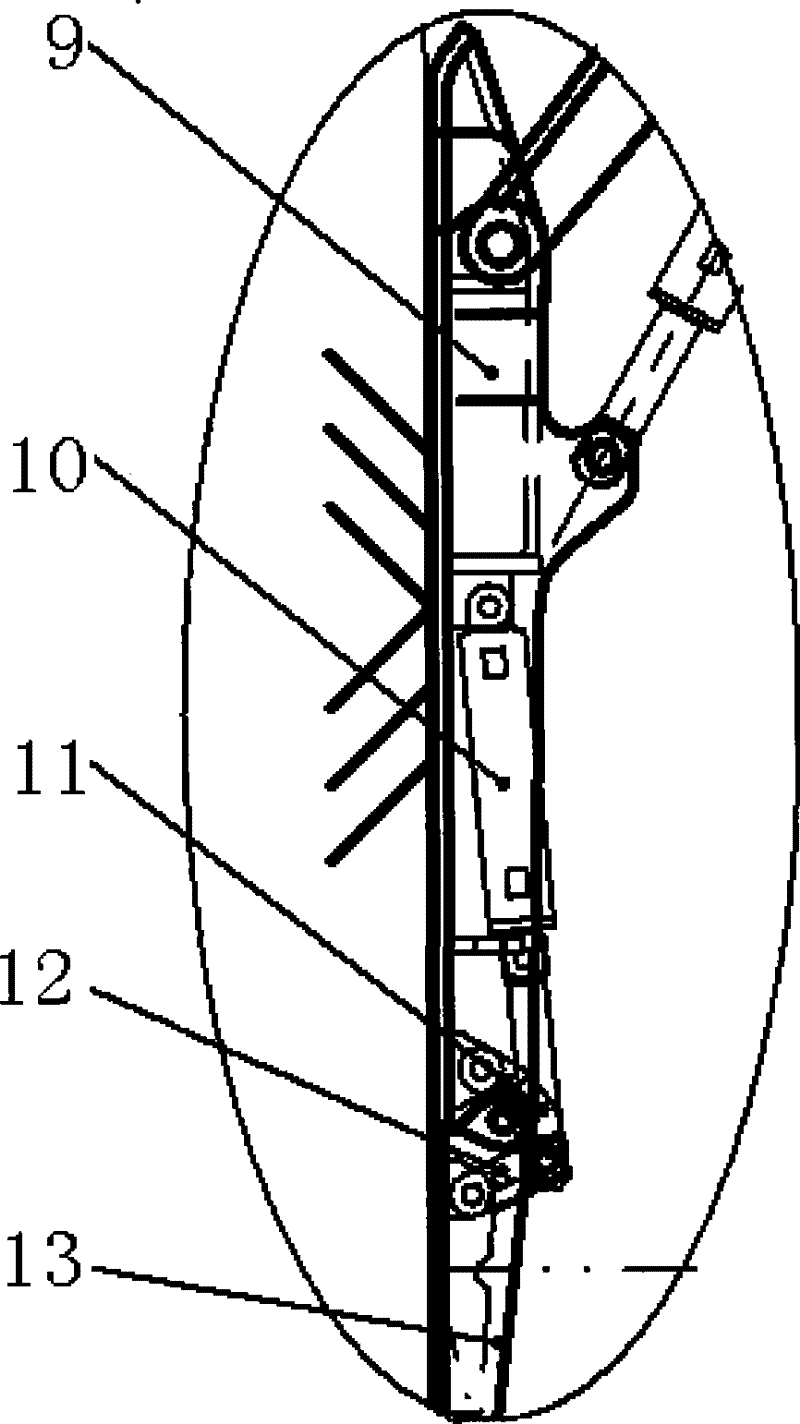

[0017] The side protection mechanism is hinged with the front end of the top beam 1, and the side protection mechanism is provided with a side protection jack, which is used to drive the side protection mechanism to rotate, so as to realize the side protection function of the side protection mechanism.

[0018] The specific support organization can include fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com