A method for early recovery of top coal in fully mechanized caving face

A technology for fully mechanized caving face and top coal, which is applied in surface mining, earthwork drilling, blasting, etc., can solve the problems of low recovery rate of top coal in fully mechanized caving mining, and achieve the effect of improving the recovery rate of top coal and safe and efficient mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

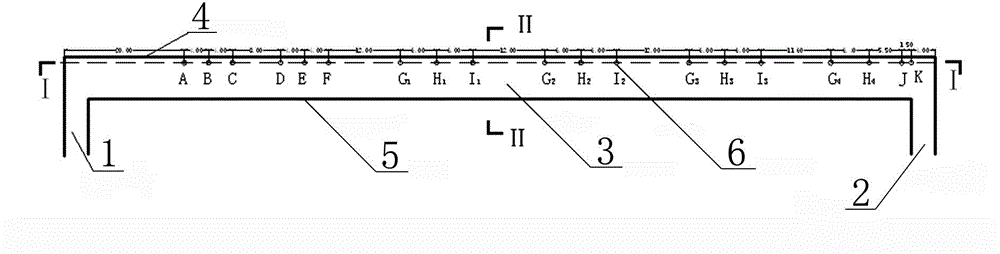

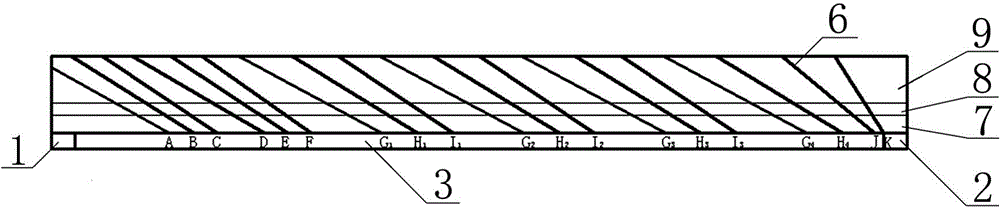

[0013] A method for recovering top coal in advance in a fully mechanized caving face, the method is realized by the following steps:

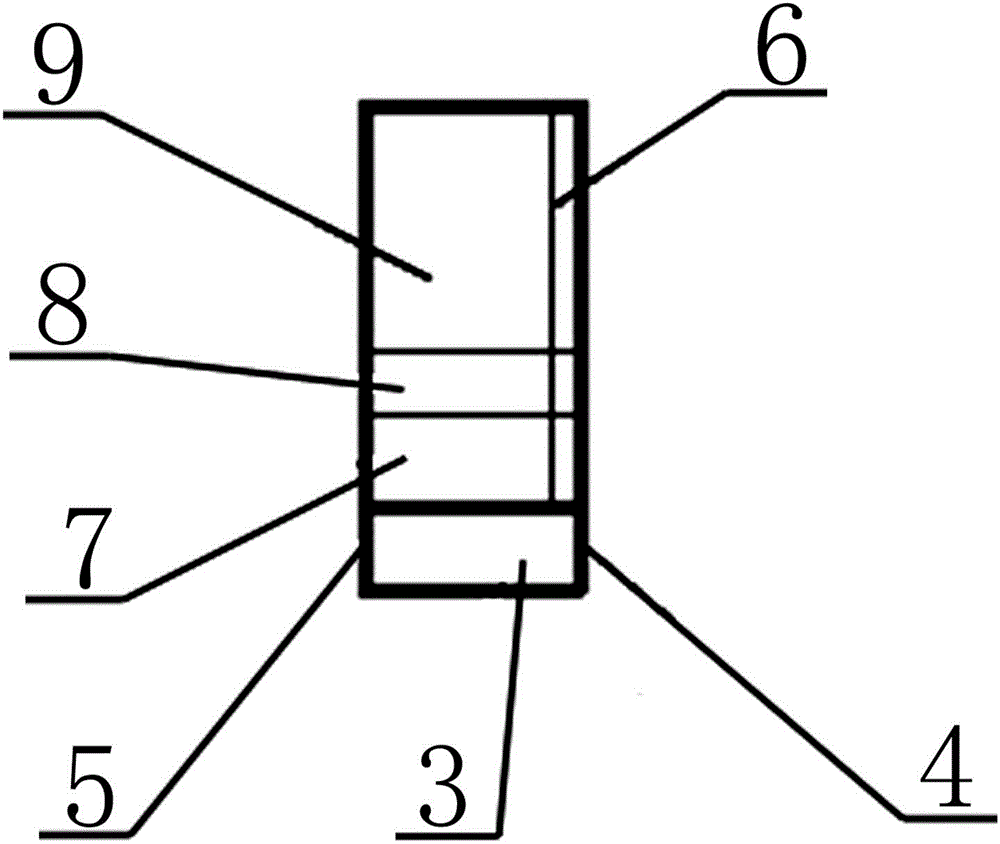

[0014] a. After the layout of the cutout hole 3 in the fully mechanized caving face is completed, a row of blastholes 6 is drilled along the axial direction of the cutout hole 3;

[0015] b. After the blast hole is drilled, mining is carried out; after mining 1 knife, explosives are loaded into the blast hole 6 and detonated, and the basic top 9 is blasted by the explosive;

[0016] c. After the blasting is completed, continue mining; after the blasted basic roof 9 collapses, start to recover the roof coal 7;

[0017] In the step a, the distance between the blast hole 6 and the outer side 4 of the incision hole is 0.3m;

[0018] In the step a, the angle of the blast hole 6 is 25°;

[0019] In the step a, the diameter of the blast hole 6 is 75mm;

[0020] In the step a, the vertical depth of the blast hole 6 is determined by the following for...

Embodiment 2

[0033] A method for recovering top coal in advance in a fully mechanized caving face, the method is realized by the following steps:

[0034] a. After the layout of the cutout hole 3 in the fully mechanized caving face is completed, a row of blastholes 6 is drilled along the axial direction of the cutout hole 3;

[0035] b. After the blast hole is drilled, mining is carried out; after 2 cuts are mined, explosives are loaded into the blast hole 6 and detonated, and the basic top 9 is blasted by the explosive;

[0036] c. After the blasting is completed, continue mining; after the blasted basic roof 9 collapses, start to recover the roof coal 7;

[0037] In the step a, the distance between the blast hole 6 and the outer edge 4 of the incision hole is 0.7m;

[0038] In the step a, the angle of the blast hole 6 is 60°;

[0039] In the step a, the diameter of the blast hole 6 is 75mm;

[0040] In the step a, the vertical depth of the blast hole 6 is determined by the following f...

Embodiment 3

[0053] A method for recovering top coal in advance in a fully mechanized caving face, the method is realized by the following steps:

[0054] a. After the layout of the cutout hole 3 in the fully mechanized caving face is completed, a row of blastholes 6 is drilled along the axial direction of the cutout hole 3;

[0055] b. After the blast hole is drilled, mining is carried out; after mining 1 knife, explosives are loaded into the blast hole 6 and detonated, and the basic top 9 is blasted by the explosive;

[0056] c. After the blasting is completed, continue mining; after the blasted basic roof 9 collapses, start to recover the roof coal 7;

[0057] In the step a, the distance between the blast hole 6 and the outer edge 4 of the incision hole is 0.5m;

[0058] In the step a, the angle of the blast hole 6 is 45°;

[0059] In the step a, the diameter of the blast hole 6 is 75mm;

[0060] In the step a, the vertical depth of the blast hole 6 is determined by the following for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com