Nonmetal composite continuous tube and electrical submersible pump system

A technology of submersible electric pump and coiled tubing, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that the viscosity of the produced fluid cannot be reduced, and achieve low viscosity, simple operation process and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below Figure 1-12 An embodiment of the present invention is described.

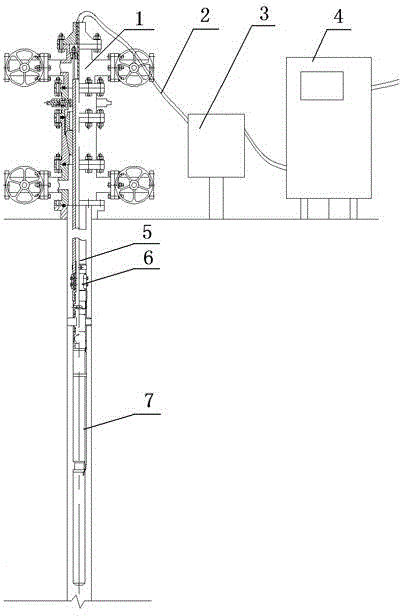

[0030] A non-metallic composite coiled tubing electric submersible pump system is composed of a nonmetallic composite coiled tubing 5, a special wellhead device 1, a downhole unit 7, a special connector 6, a surface cable 2, a junction box 3, and a control cabinet 4.

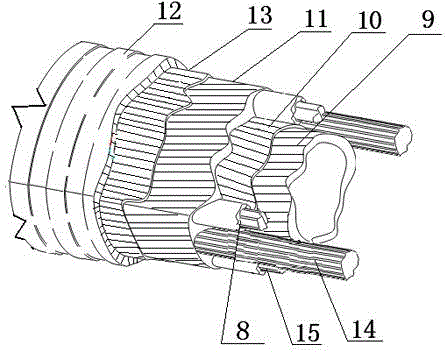

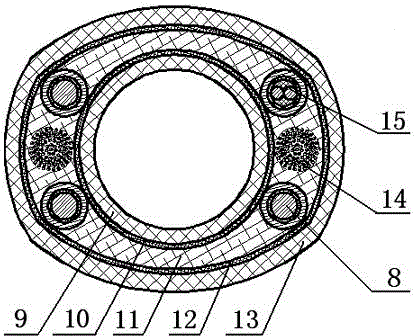

[0031] The core of the non-metallic composite coiled tubing 5 is circular, and is used to transport the production fluid of the downhole unit; the pipe wall from the inside to the outside is the inner pipe 9, the inner steel wire mesh 10, the embedded layer 11, and the outer steel wire mesh 12 , protective layer 13. Two steel ropes 14 symmetrically arranged are embedded in the embedding layer 11, and the direction of rotation of the two steel ropes is opposite, such as: the twist of one steel rope is left-handed, and the twist of the other steel rope is right-handed; There are four cables arranged on both sides of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com