Polyethylene resin for tubular material and preparation method and composition thereof

A technology of polyethylene resin and composition, which is applied in the field of polyethylene resin and its preparation method and its composition, can solve the problems of complex process and high cost, and achieve the effect of high hydrostatic strength and excellent resistance to slow crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

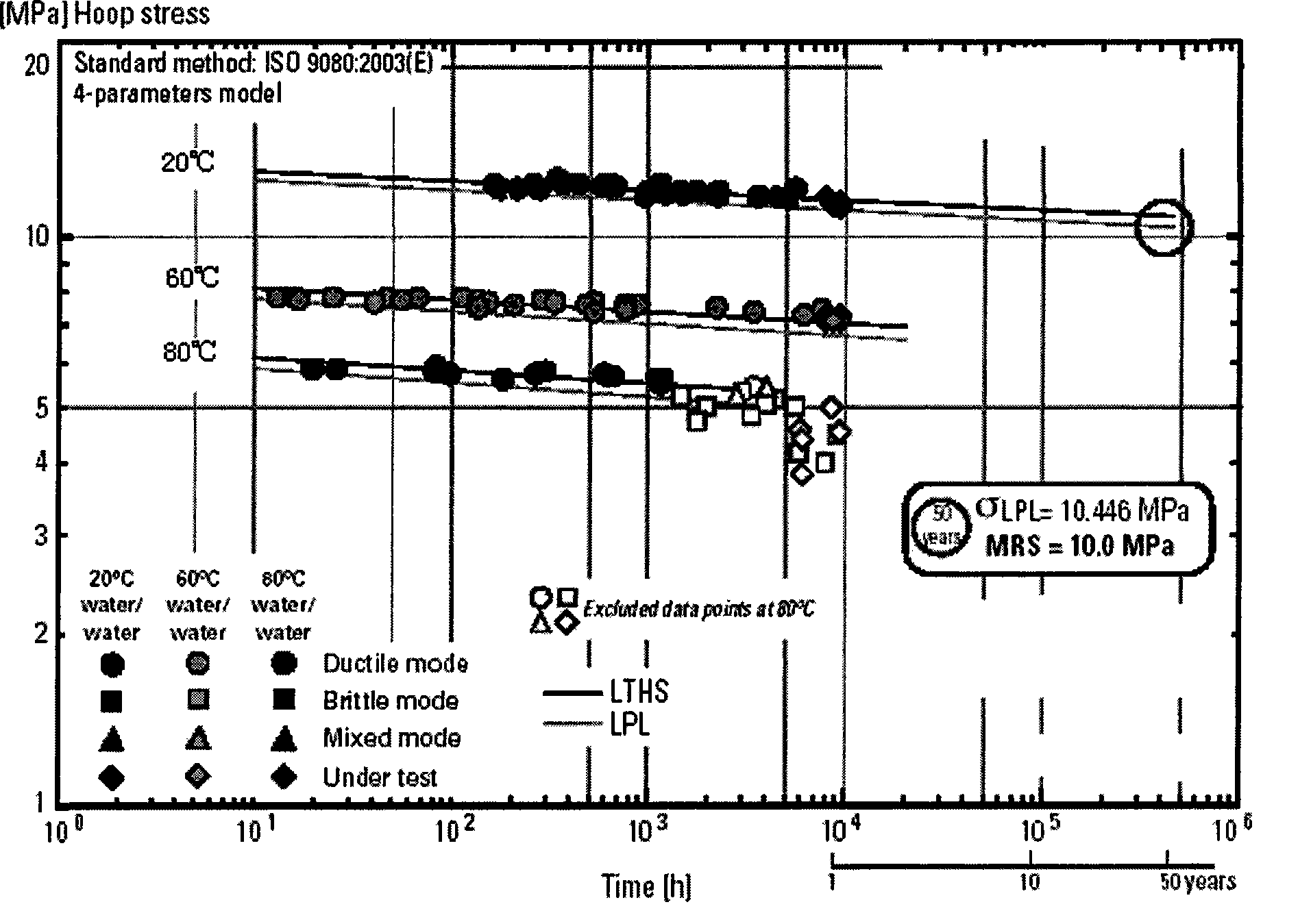

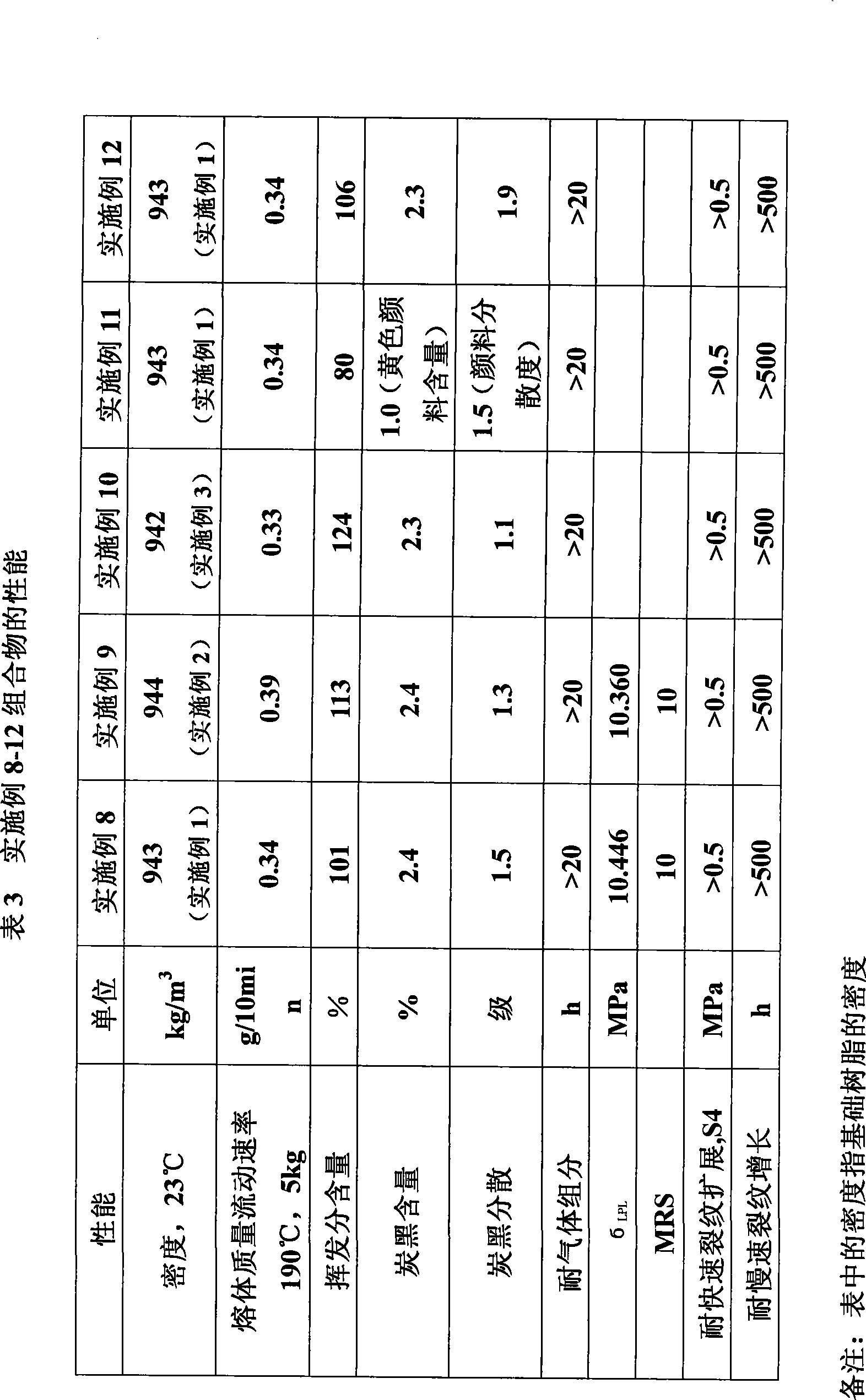

Examples

Embodiment 1

[0042] Using the Unipol gas-phase polyethylene process, ethylene, hydrogen and comonomers are introduced into the gas-phase fluidized bed reactor, and the polyethylene resin is reacted under the action of a catalyst. The catalyst is bistriphenylsilane chromate supported on silica gel. Aluminum / chromium=6.0:1.

[0043] See Table 1 for production conditions and Table 2 for resin properties.

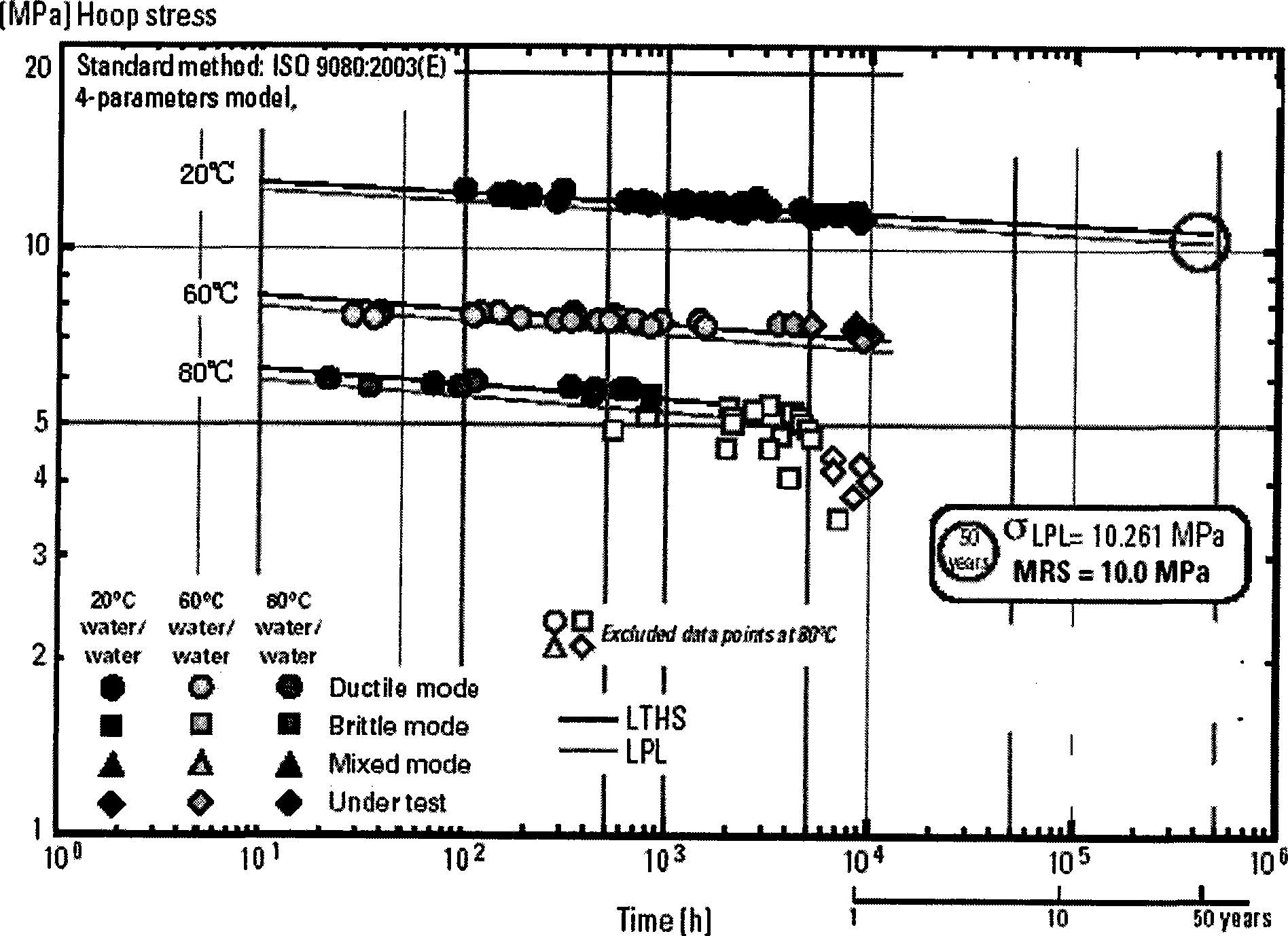

[0044] After the polyethylene resin is prepared into a ф32×3mm pipe, according to the provisions of ISO / TR 9080, the statistical result σ of the expected hydrostatic strength when extrapolated to 20°C and subjected to water pressure for 50 years LPL The value is 10.261MPa. Extrapolation results are attached figure 1 .

Embodiment 2

[0046] Using the Unipol gas-phase polyethylene process, ethylene, hydrogen and comonomers are introduced into the gas-phase fluidized bed reactor, and the polyethylene resin is reacted under the action of a catalyst. The catalyst is bistriphenylsilane chromate supported on silica gel. Aluminum / chromium=5.0:1.

[0047] See Table 1 for production conditions and Table 2 for resin properties.

[0048] After the polyethylene resin is prepared into a ф32×3mm pipe, according to the provisions of ISO / TR 9080, the statistical result σ of the expected hydrostatic strength when extrapolated to 20°C and subjected to water pressure for 50 years LPL The value is 10.182MPa.

Embodiment 3

[0050] Using the Unipol gas-phase polyethylene process, ethylene, hydrogen and comonomers are introduced into the gas-phase fluidized bed reactor, and the polyethylene resin is reacted under the action of a catalyst. The catalyst is bistriphenylsilane chromate supported on silica gel. Aluminum / chromium=5.5:1.

[0051] See Table 1 for production conditions and Table 2 for resin properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com