Medium high voltage anode aluminum foil corrosion method

An anode aluminum foil, medium and high voltage technology, applied in the direction of electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of reduced service life of products, difficulty in removing metal impurities, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

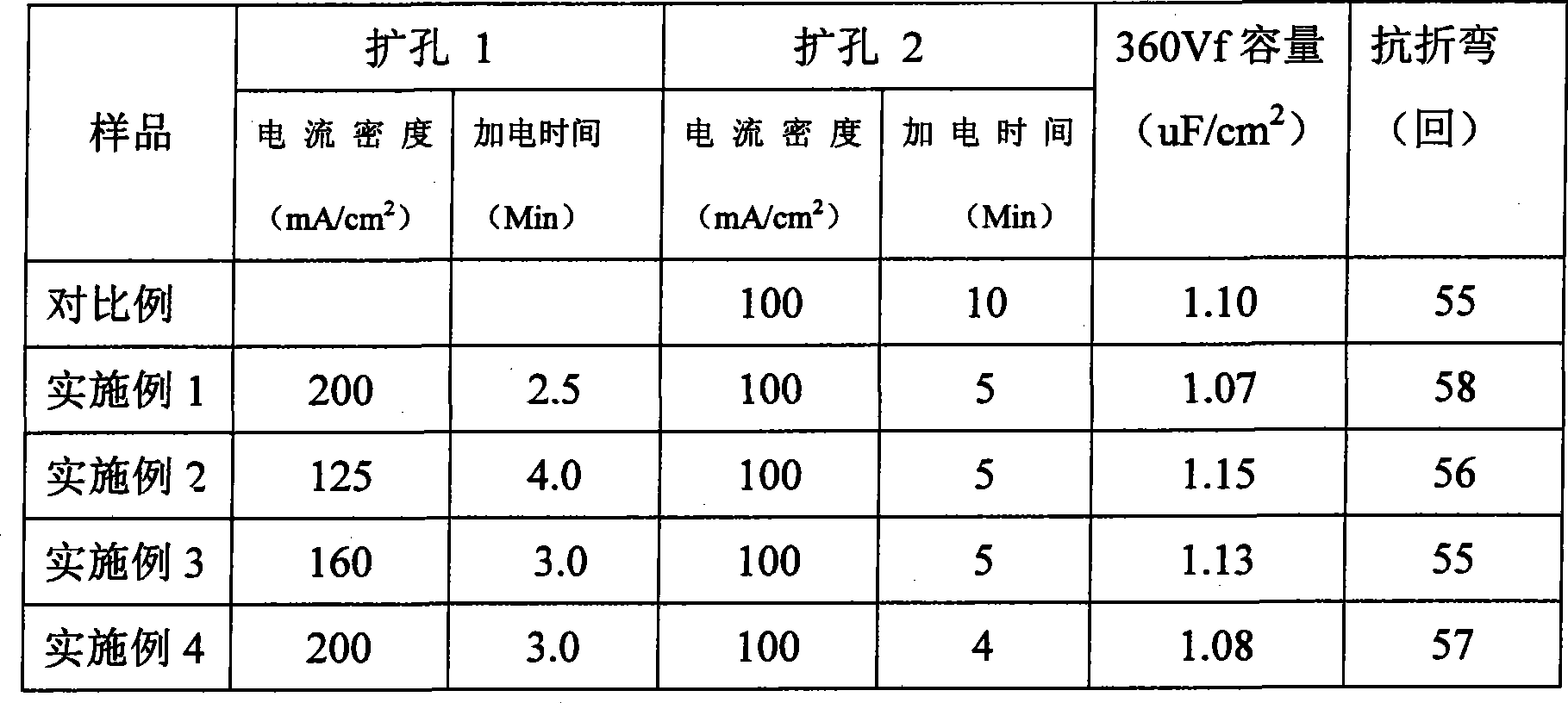

Embodiment 1

[0027] Hole expansion corrosion is divided into two steps, the first current density is 200mA / cm 2 , the bath is 4% nitric acid, corroded for 2.5 minutes, and the current density of the second step of hole expansion is 100mA / cm 2 , the bath solution is 2% nitric acid, corroded for 5 minutes, and other processes include pre-treatment, corroding and post-treatment, which are the same as those of the comparative example.

Embodiment 2

[0029] Hole expansion corrosion is divided into two steps, the first current density is 125mA / cm 2 , the bath solution is 4% nitric acid, corroded for 4 minutes, and the current density of the second step of hole expansion is 100mA / cm 2 , the bath solution is 2% nitric acid, corroded for 5 minutes, and other processes include pre-treatment, corroding and post-treatment, which are the same as those of the comparative example.

Embodiment 3

[0031] Hole expansion corrosion is divided into two steps, the first current density is 160mA / cm 2 , the bath solution is 4% nitric acid, corroded for 3 minutes, and the current density of the second step of hole expansion is 100mA / cm 2 , the bath solution is 2% nitric acid, corroded for 5 minutes, and other processes include pre-treatment, corroding and post-treatment, which are the same as those of the comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com