Design method for transition curve path section

A design method and curve technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as vehicle impact, affecting driving safety, and occupant discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

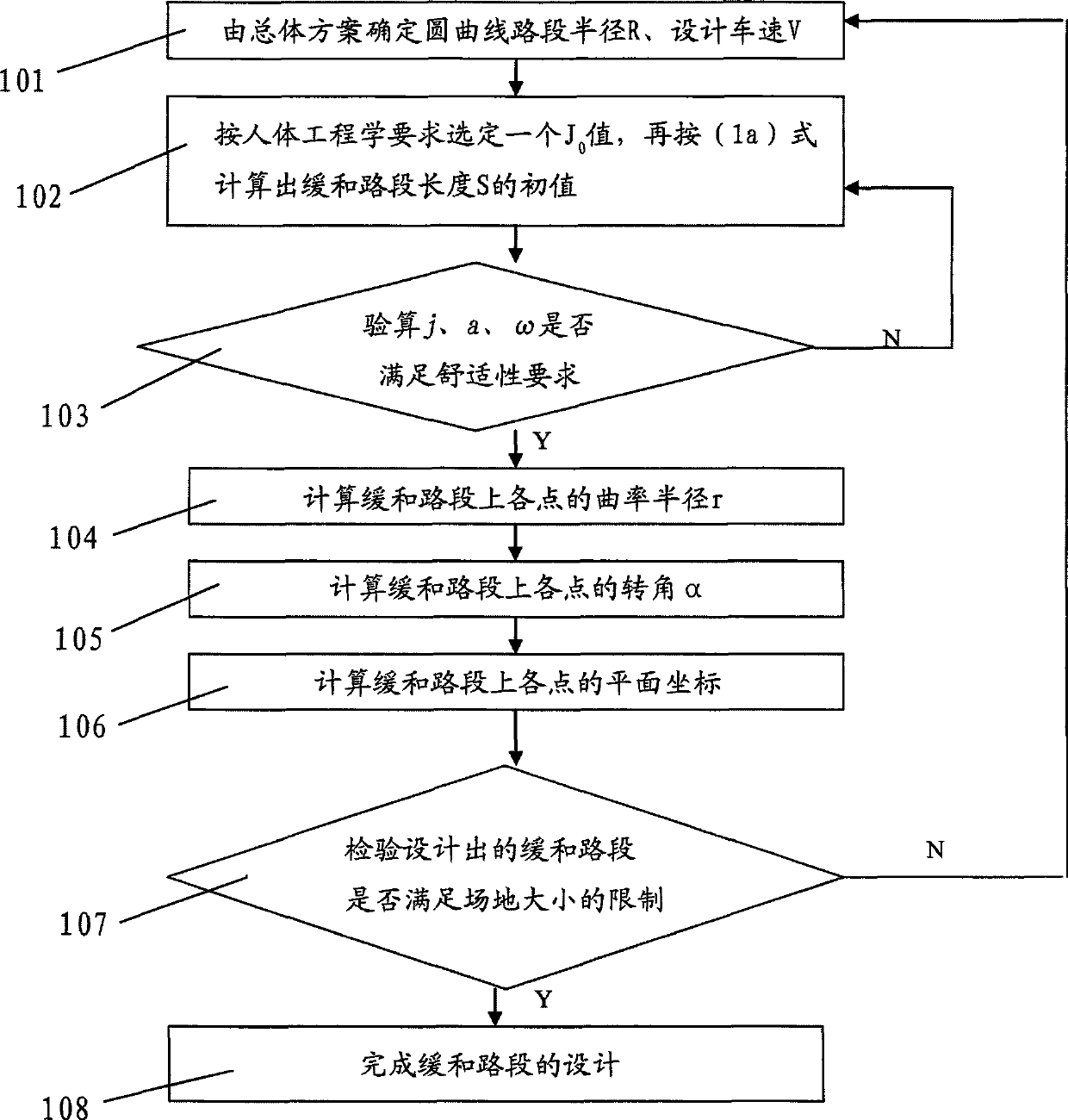

Method used

Image

Examples

Embodiment Construction

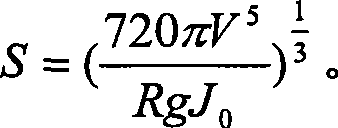

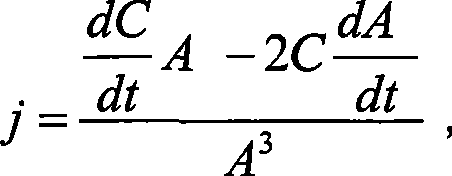

[0033] The principle of the design transitional curve section of the present invention is: make the centrifugal force of the traveling vehicle on the transitional curve section change in a smooth function mode from the starting point to the end point of the transitional curve section, that is, make the centrifugal force of the vehicle change from the zero value of the straight point to the specified The smooth function changes regularly to a rounded point.

[0034] The curve equation of this spiral section is: 1 r = 1 πR ( lπ S - 1 2 sin 2 lπ S ) - - - - - - - - - - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com