Mounting structure for car front cover decorating parts

A technology for installing structures and decorative parts, which is applied to superstructures, vehicle parts, superstructure subassemblies, etc., can solve problems such as unreliable installation, wear, and insufficient interference, and achieve the effect of ensuring the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

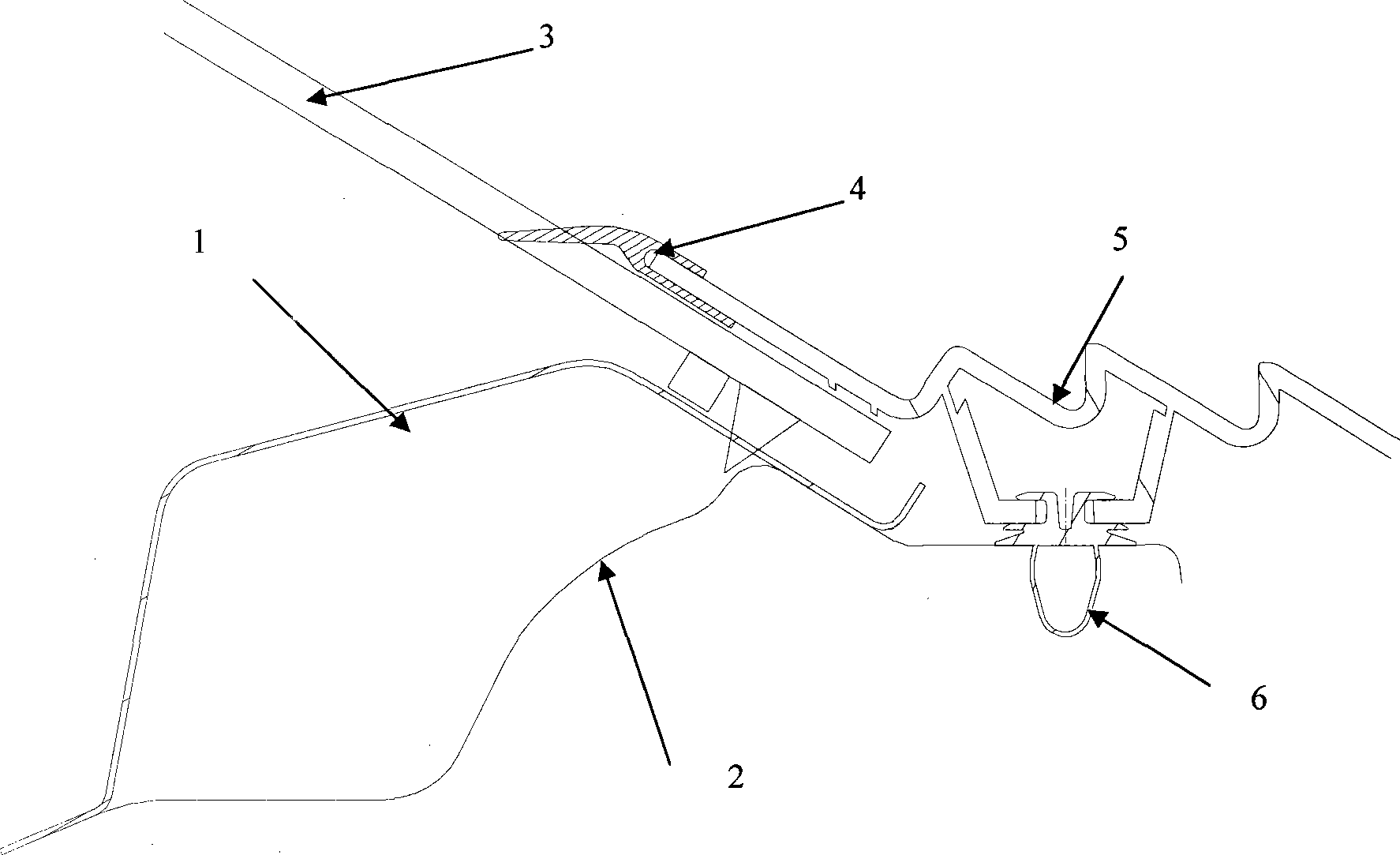

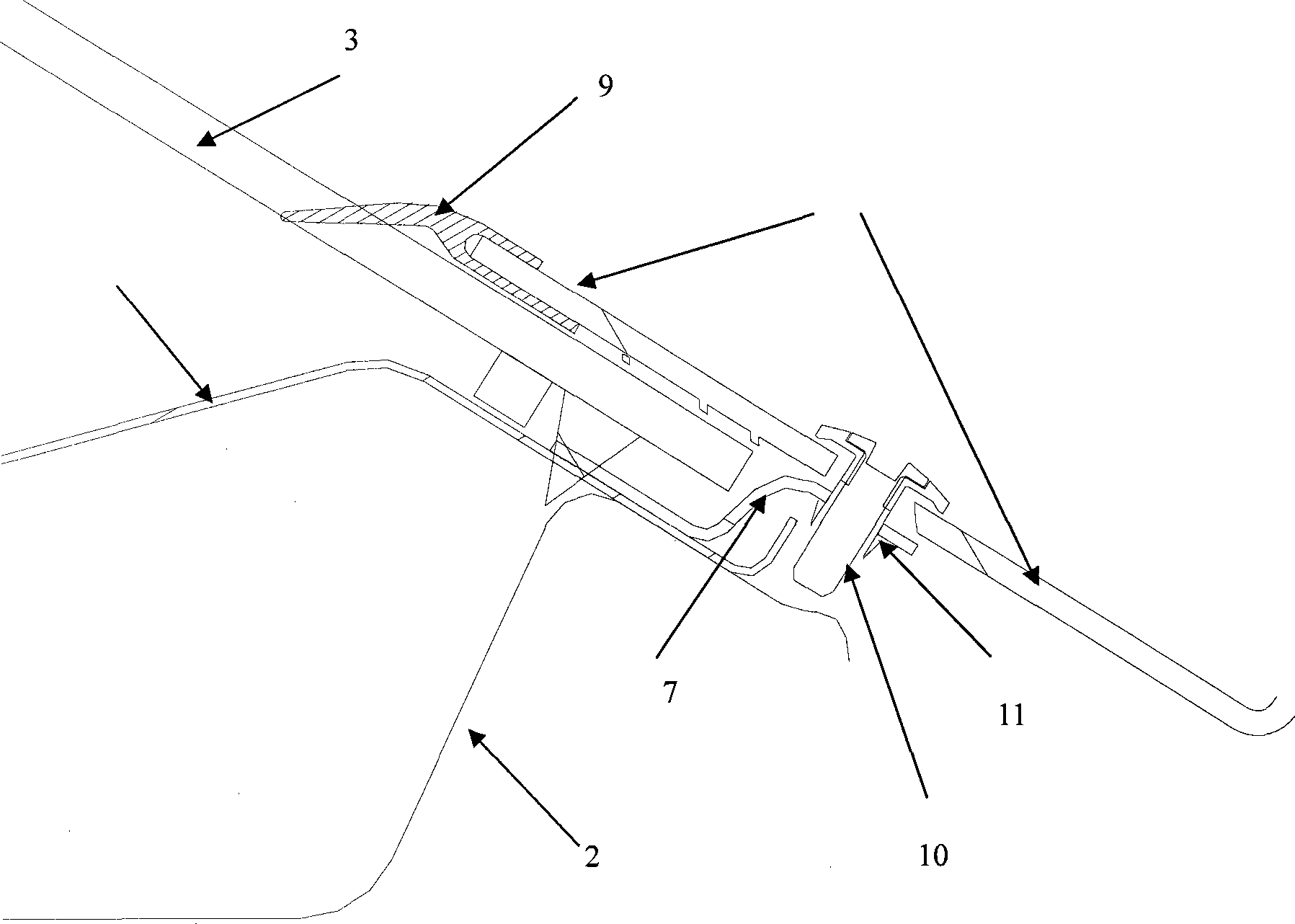

[0011] Such as figure 2 As shown, the windshield cowl 1 and the windshield cowl support 2 are welded to form a windshield cowl welding assembly, and the lower plane of the Z-shaped connecting bracket 7 is fixed on the assembly by welding, and is located on the windshield. Inside the lower edge of the glass 3, the upper plane of the Z-shaped connecting bracket 7 protrudes obliquely from the lower edge of the windshield, and is flush with the plane of the windshield. 7, and stick to the front windshield 3 by the front hood trim fitting adhesive strip 9 on the upper edge. This pressing force is realized by the fixing of the front hood trim 8 and the Z-shaped connecting bracket 7. The adhesive tape 9 for attaching the front cover trim is fixed on the upper edge of the front cover trim 8 by clipping.

[0012] The snap-in button is composed of a snap-in button cylinder 10 and a snap-in button sleeve 11. The lower end of the snap-in button sleeve 11 has elastic claws. The snap-in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com