Glazing inspection

A glass window and image technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of information loss, low combination response, determining whether there is a defect or whether it meets the pass/fail standard and other complicated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

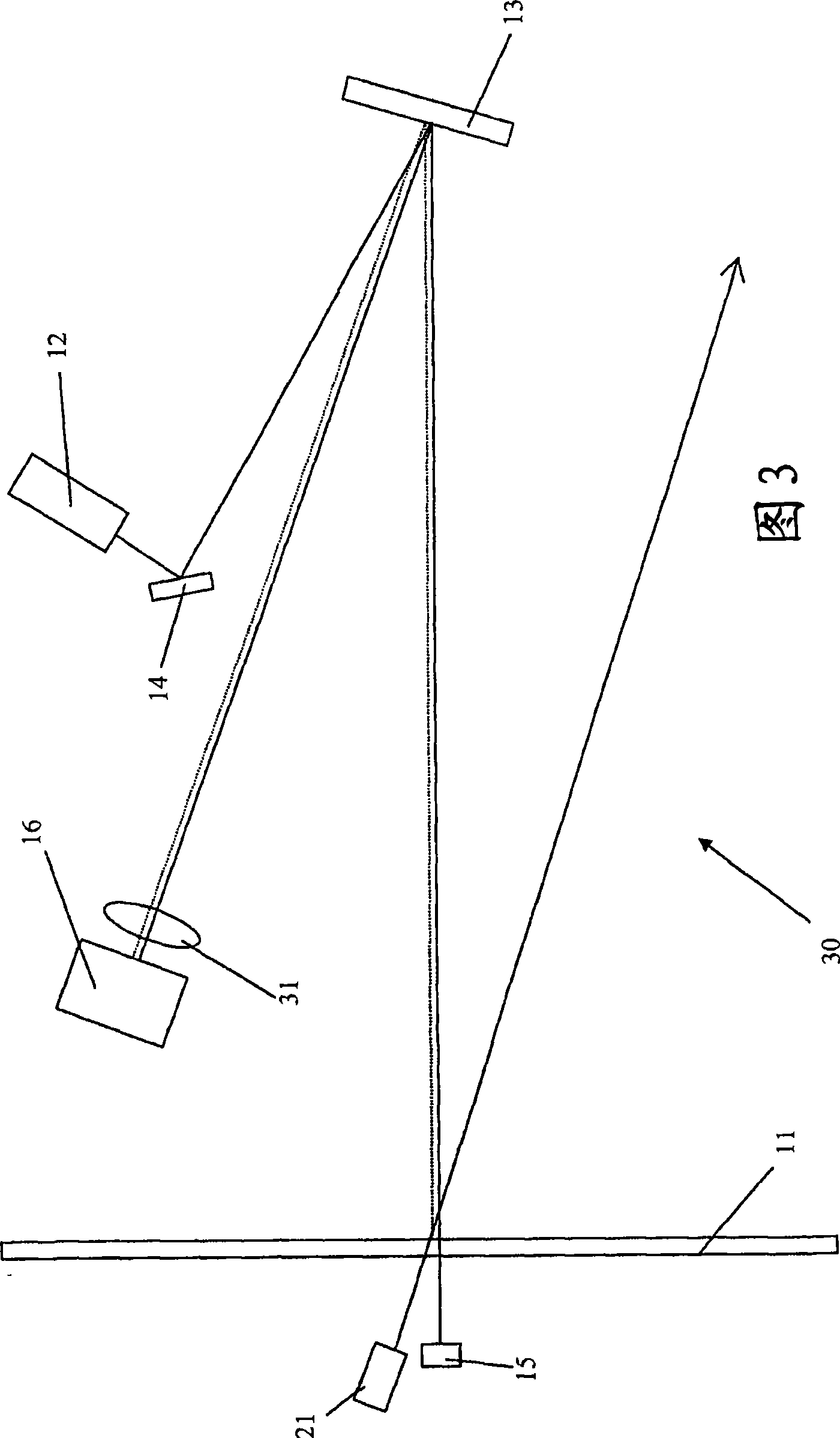

[0019] In the present invention, it has been recognized that light from two light sources of different wavelengths can be used to generate brightfield and darkfield images of defects in the glazing and can be detected using one image capture device. By successfully combining brightfield and darkfield techniques, shadowed images of glass windows can also be produced using the same light source as that used for brightfield images.

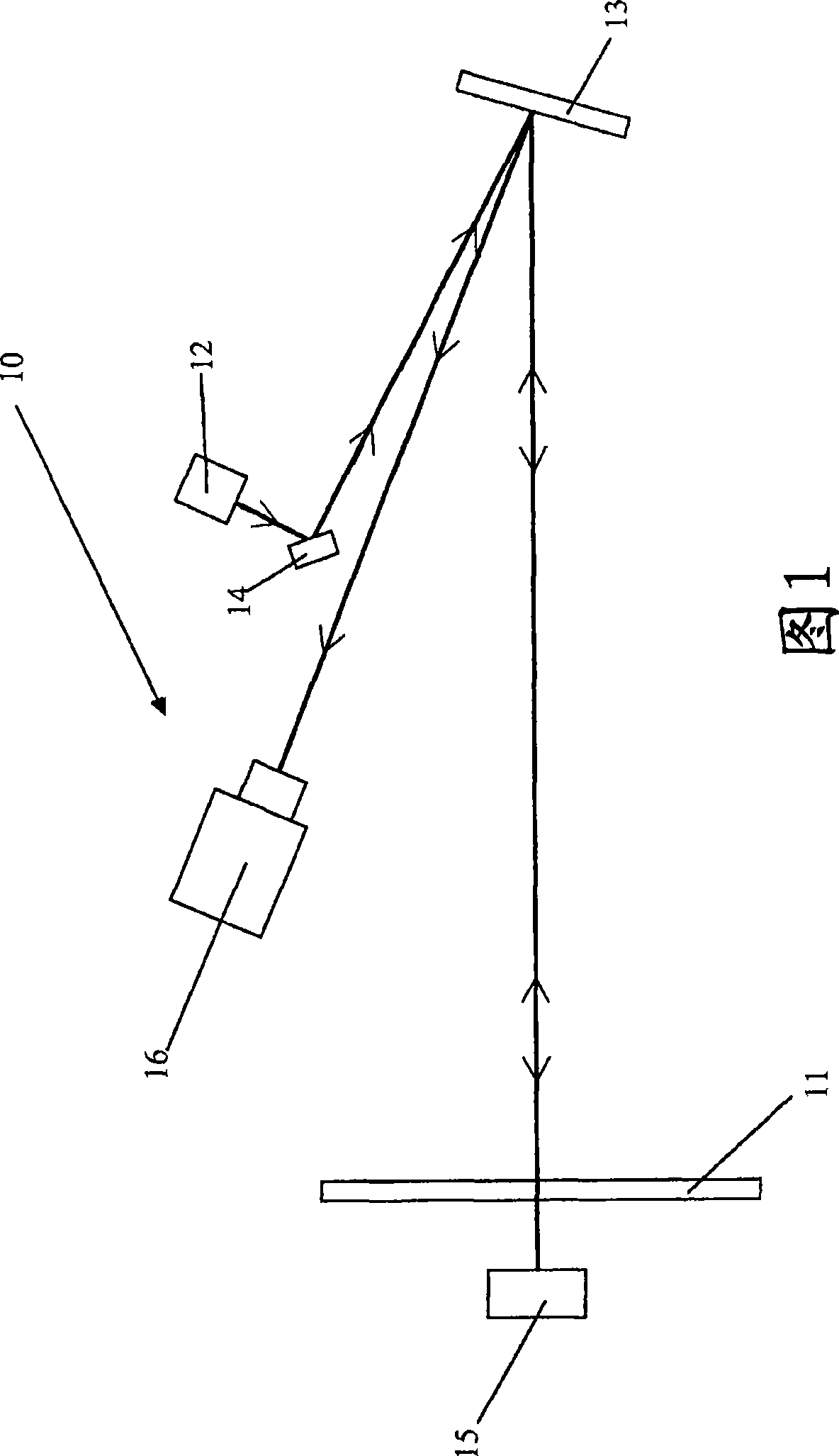

[0020] Figure 1 is an exemplary ray diagram of an optical inspection setup set up for brightfield imaging. An optical inspection apparatus 10 is shown in which a glazing 11 (supported on not shown supports) in position is inspected in transmitted light. The device 10 comprises an LED (Light Emitting Diode) point light source 12 emitting light reflected by a large reflector 13 and incident on a glass window 11 . The light from the LED point light source 12 is directed by the small reflector 14 to the large reflector. The strip spherical mirror 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com