Cotton cleaning mechanism and constituted cotton-picker

A cotton picker and flower cleaning technology, which is applied to agricultural machinery and tools, picking machines, harvesters, etc., can solve the problems of large amount of impurities in machine-picked cotton, affecting the application effect, and aggravating cotton fiber damage, etc., to achieve cleaning of impurities Improved effect, simple structure, and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

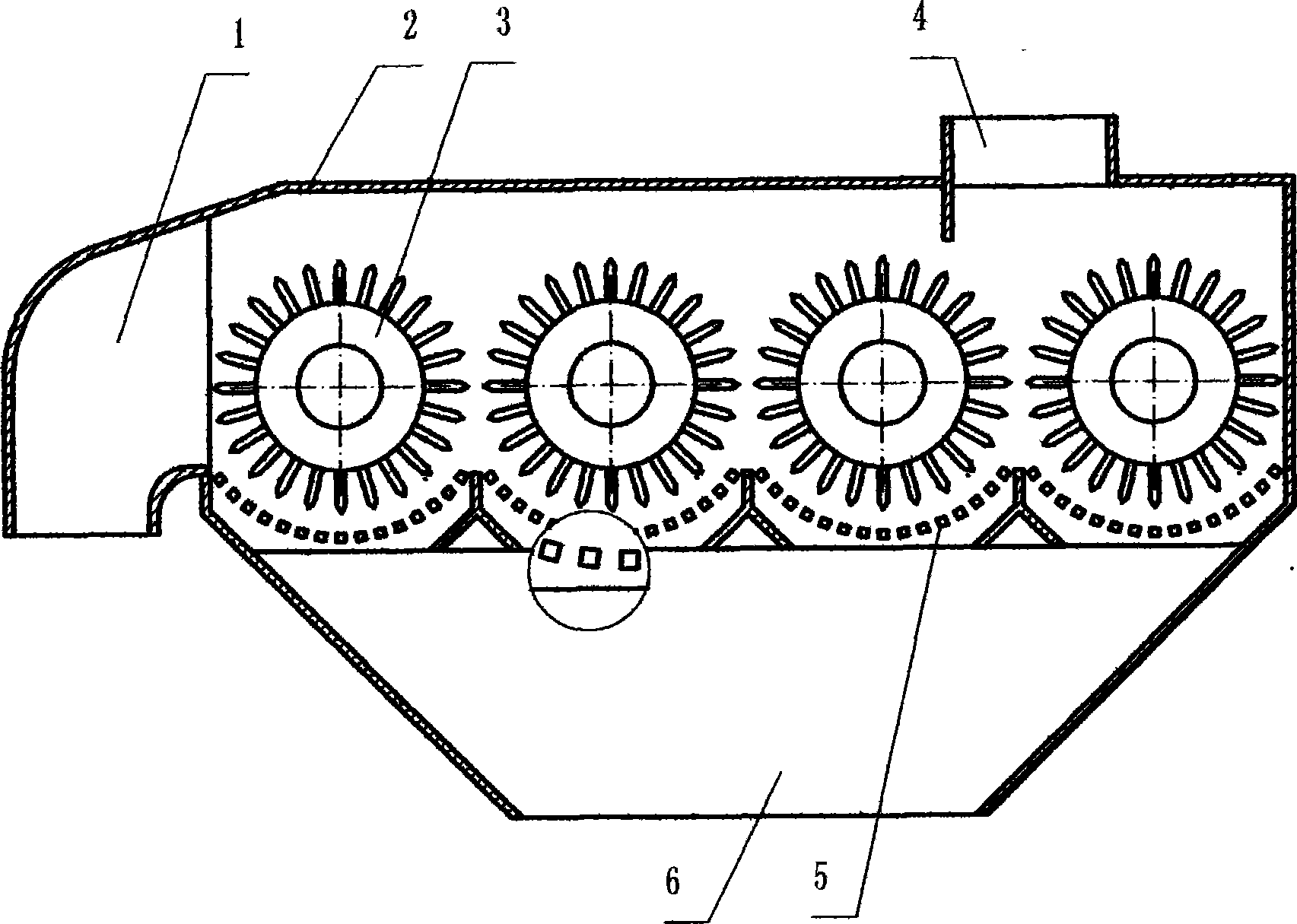

[0016] Embodiment 1: refer to figure 1 , is the embodiment 1 of the cleaning mechanism of the present invention, including the casing 2, the cotton inlet 4, the cotton outlet 1, the licker-in 3 and the miscellaneous discharge port 6, and the whole machine is provided with 4 licker-in horizontally arranged side by side, and the licker-in 3. The bottom is provided with an impurity removal screen 5, the impurity removal screen 5 is a grid and the cross-section of the ribs forming the impurity removal screen 5 is rectangular.

Embodiment 2

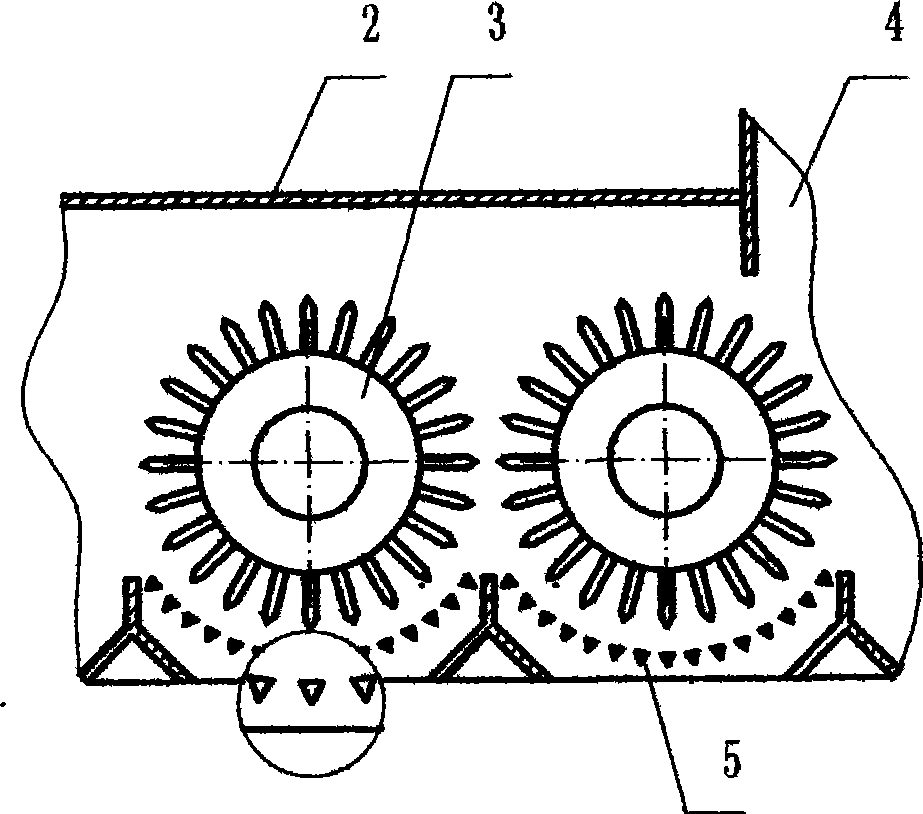

[0017] Embodiment 2: refer to figure 2 , is a schematic structural view of Embodiment 2 of the cleaning mechanism of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the cross-section of the ribs constituting the impurity removal screen 5 is triangular.

Embodiment 3

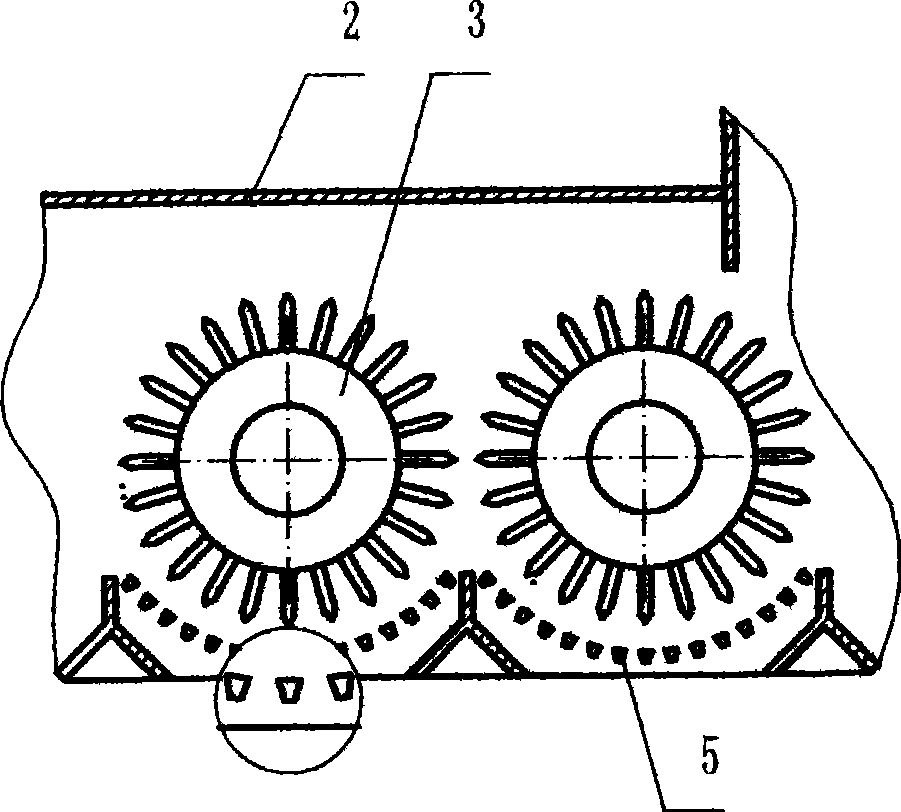

[0018] Embodiment 3: refer to image 3 , is a schematic structural view of Embodiment 3 of the cleaning mechanism of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the whole machine is provided with 6 licker-in rollers arranged horizontally side by side, and the cross-section of the ribs constituting the impurity removal screen 5 is trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com