Semiconductor measuring probe bench with rotatable probe card

A technology for measuring probes and probe cards, which is used in semiconductor/solid-state device testing/measurement, measuring electricity, measuring devices, etc. Accuracy, effect of small test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

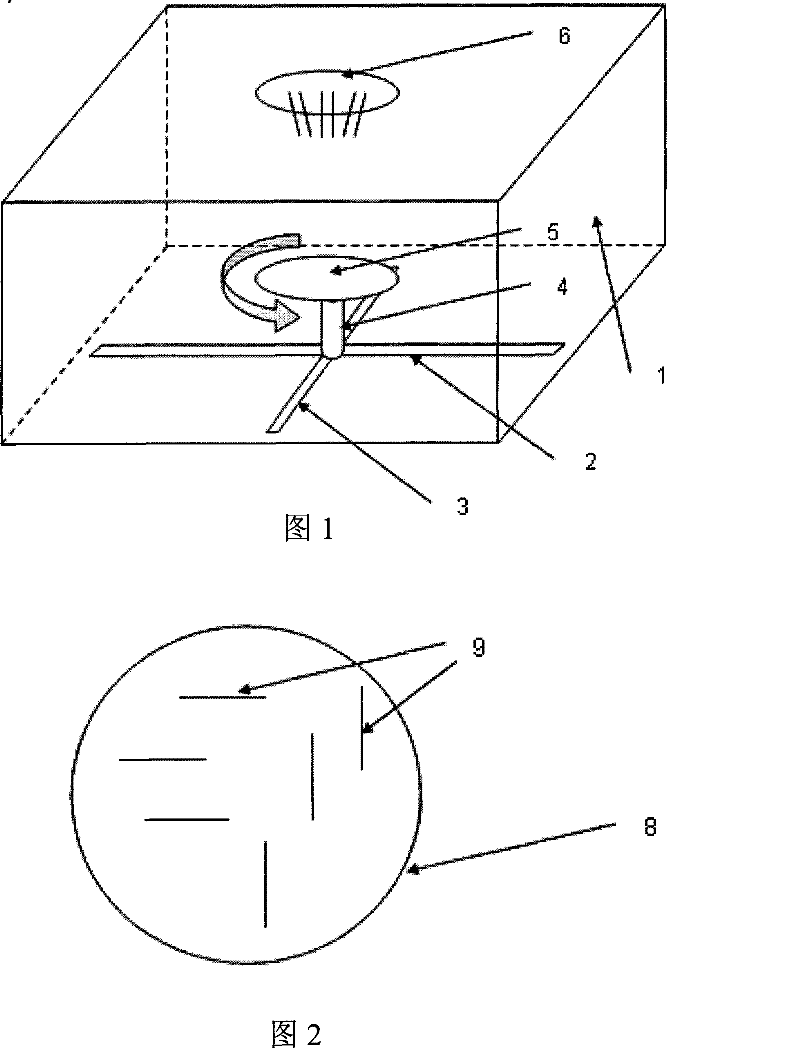

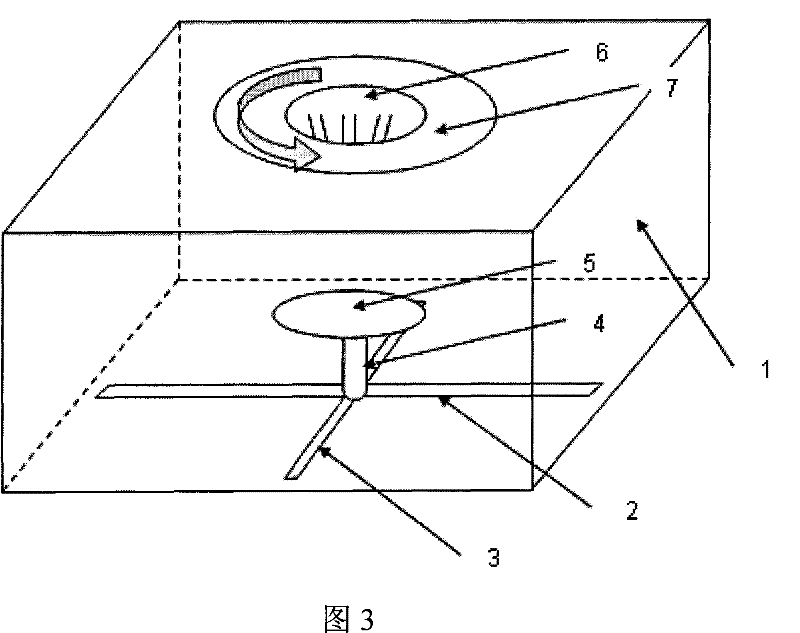

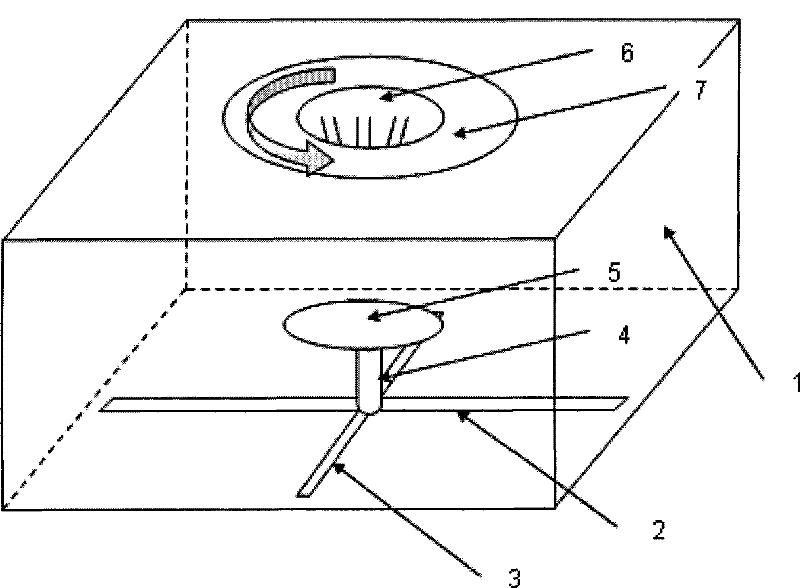

[0017] The semiconductor measuring probe station of the rotatable probe card according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] In the semiconductor manufacturing process, component parameter measurement is a very important monitoring step. By measuring the electrical parameters of components such as resistors, capacitors, and transistors in the test key 9 of the wafer 8, the characteristics of the components and problems on the production line can be reflected.

[0019] The present invention improves the traditional method, adopts the concept of relative motion, does not rotate the wafer carrier 5, but rotates the probe card 6 to measure the wafer. First, a controllable rotating device 7 is arranged on the main body top plane of the probe station 1, so that the probe card mounted on it is opposite to the wafer carrier below, and the rotating device 7 is controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com