Multi-part cooled piston for an internal combustion engine

An internal combustion engine, multi-part technology, applied to pistons, mechanical equipment, engine components, etc., to solve problems such as loose threaded connections, cracks, engine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

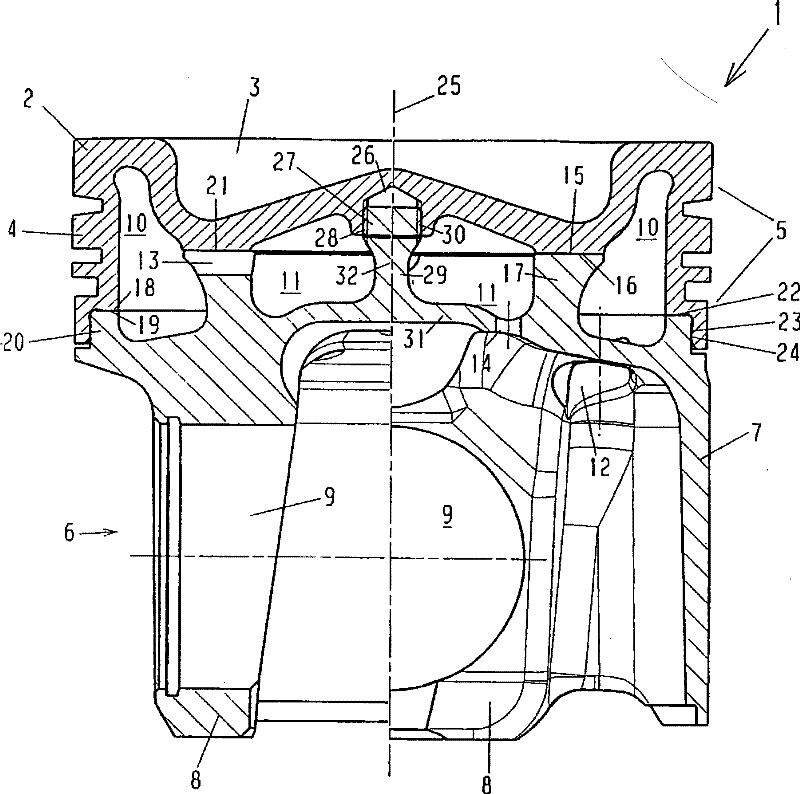

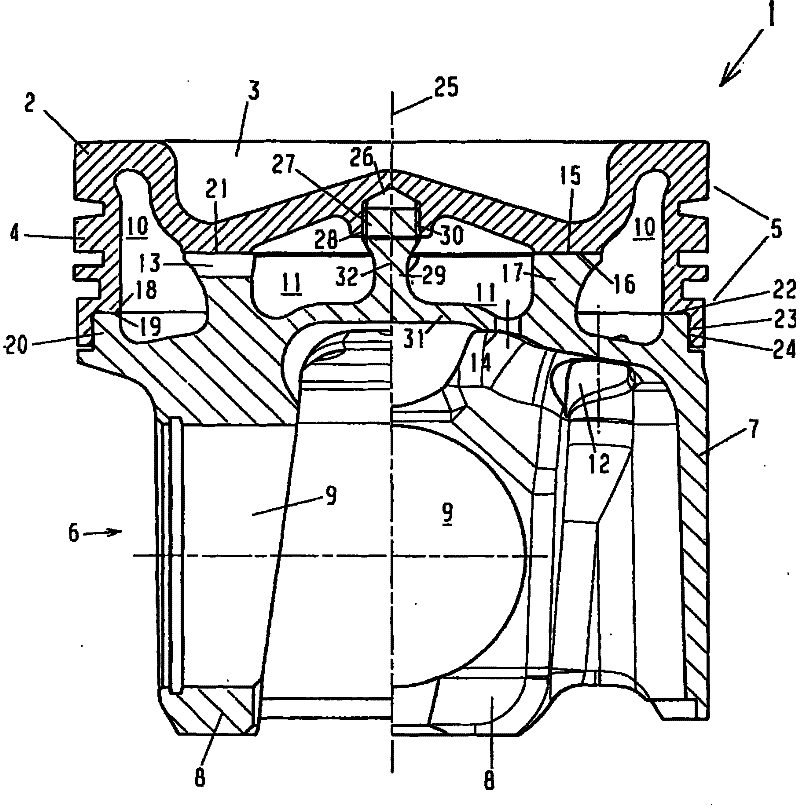

[0006] The figure shows a multi-part cooled piston 1 consisting of a piston upper part 2 and a piston lower part 6 with a crown pocket 3 and an annular wall 4 with a piston ring 5, which The lower piston part has a box-shaped piston skirt 7 and two pin seats 8 connected thereby, which each have a pin hole 9 for receiving a piston pin (not shown in the figure). The upper piston part 2 and the lower piston part 6 delimit an outer annular cooling channel 10 and an inner annular cooling channel 11 arranged concentrically thereto, wherein the outer cooling channel 10 has at least one oil inlet for introducing cooling oil port 13 and is connected to the internal cooling channel 11 via at least one overflow channel 13 . The overflow channel 13 can be designed as a bore. The inner cooling channel 11 has at least one oil outlet opening 14 through which cooling oil can escape from the inner cooling channel 11 . The upper piston part 2 and the lower piston part 6 can be made of steel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com