Elevator hoisting rope replacement method and traction device equipment used for replacement

A replacement method and rope technology, which are applied to lifting equipment, mechanical equipment, elevators and other directions in mines, can solve problems such as incompatibility and insufficient mechanical pulling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

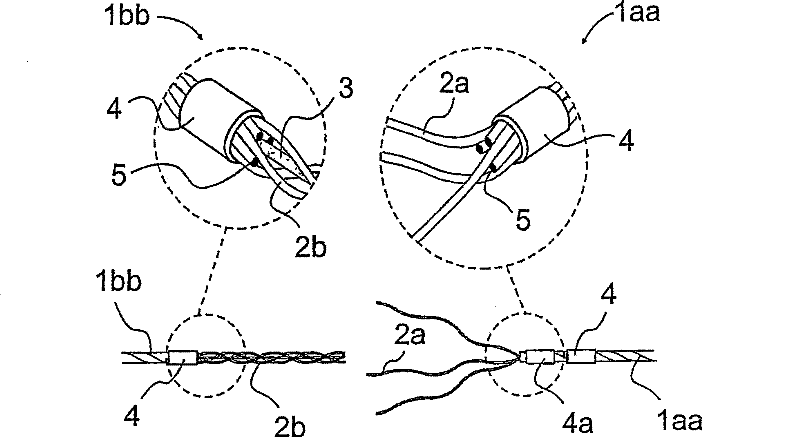

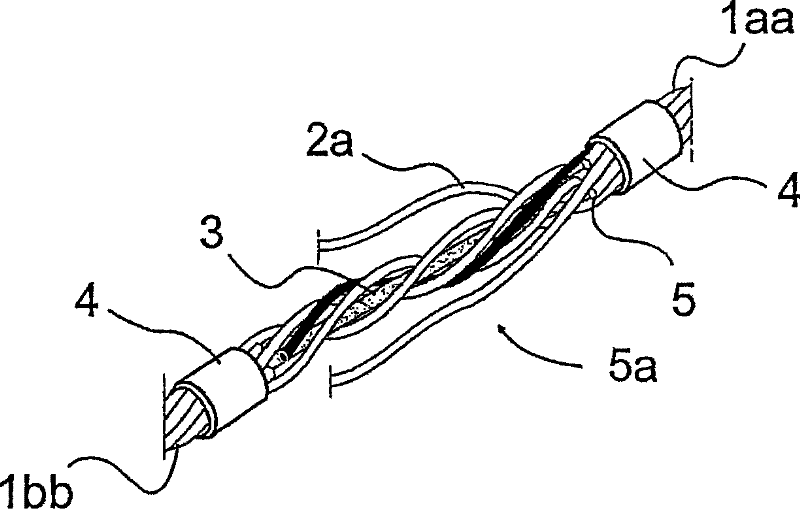

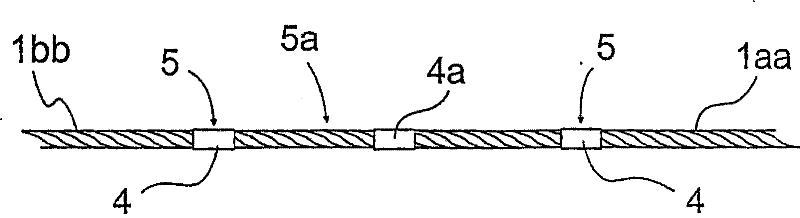

[0069] figure 1 The hoisting ropes 1aa of the new hoisting rope 1a and the hoisting ropes 1bb of the old hoisting rope 1b are shown opened at their respective ends. The hoisting ropes 1aa and 1bb are unraveled at their ends by substantially the same length as each other, which length is an appropriate distance for this purpose, and every other strand of each rope is cut off corresponding to The length of this distance. The core of the hoisting rope 1aa is also cut off by a length corresponding to this distance. In this case, each hoisting rope according to this example has three remaining strands 2a, 2b each, while the hoisting rope 1bb also has a core 3 left. Before each strand is unraveled and cut off, a suitable number of thin and relatively short sleeves 4, 4a are screwed onto the rope, the diameter of said sleeves being only slightly larger than the outer diameter of the rope, in this case Under normal circumstances, the sleeves 4, 4a are just sleeved on the rope. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com