Temperature-regulating handle structure of constant-temperature tap

A technology for thermostatic faucets and handles, applied to valve operation/release devices, valve details, engine components, etc., can solve problems such as cumbersome operation, and achieve the effect of simple appearance and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

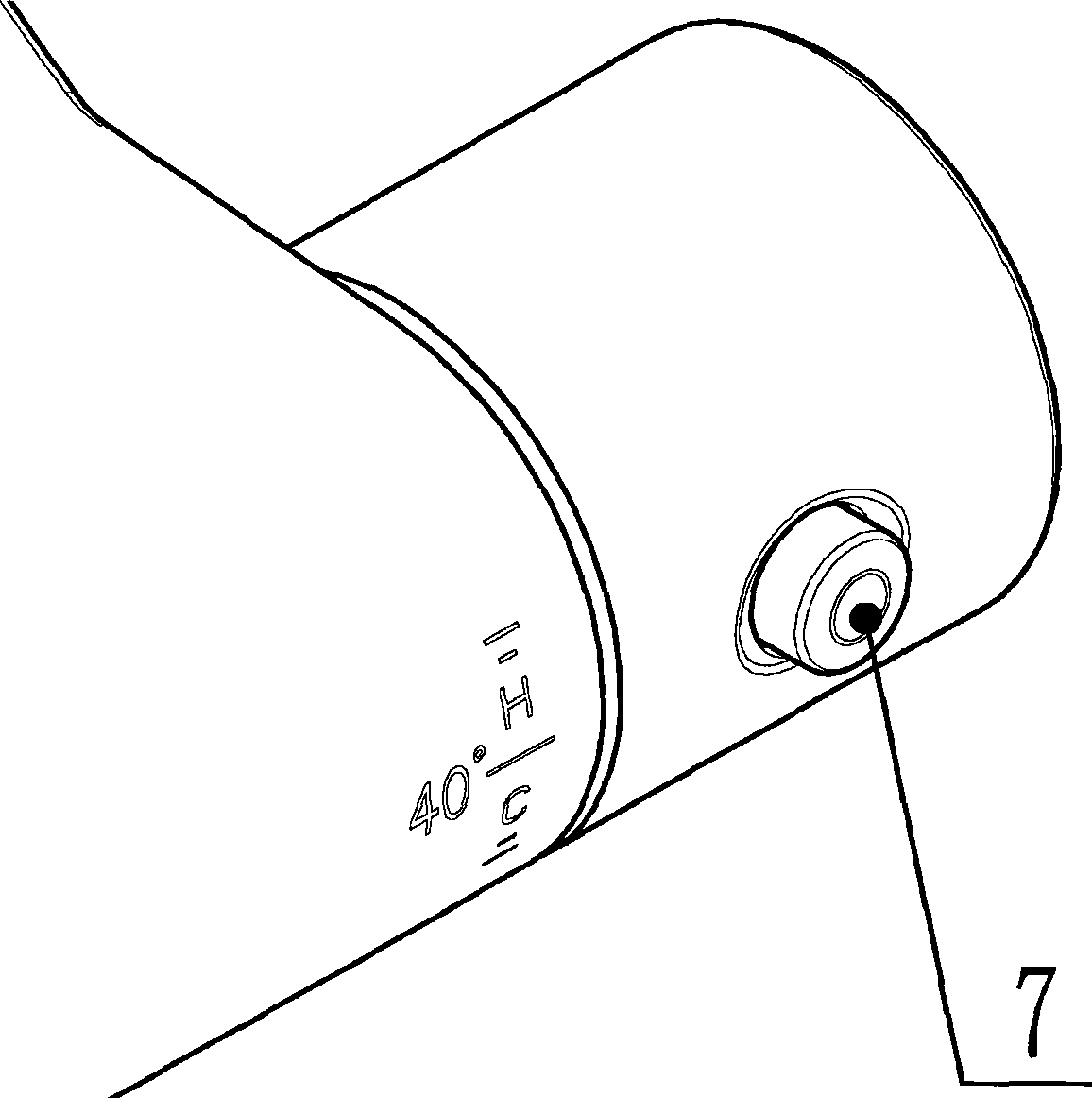

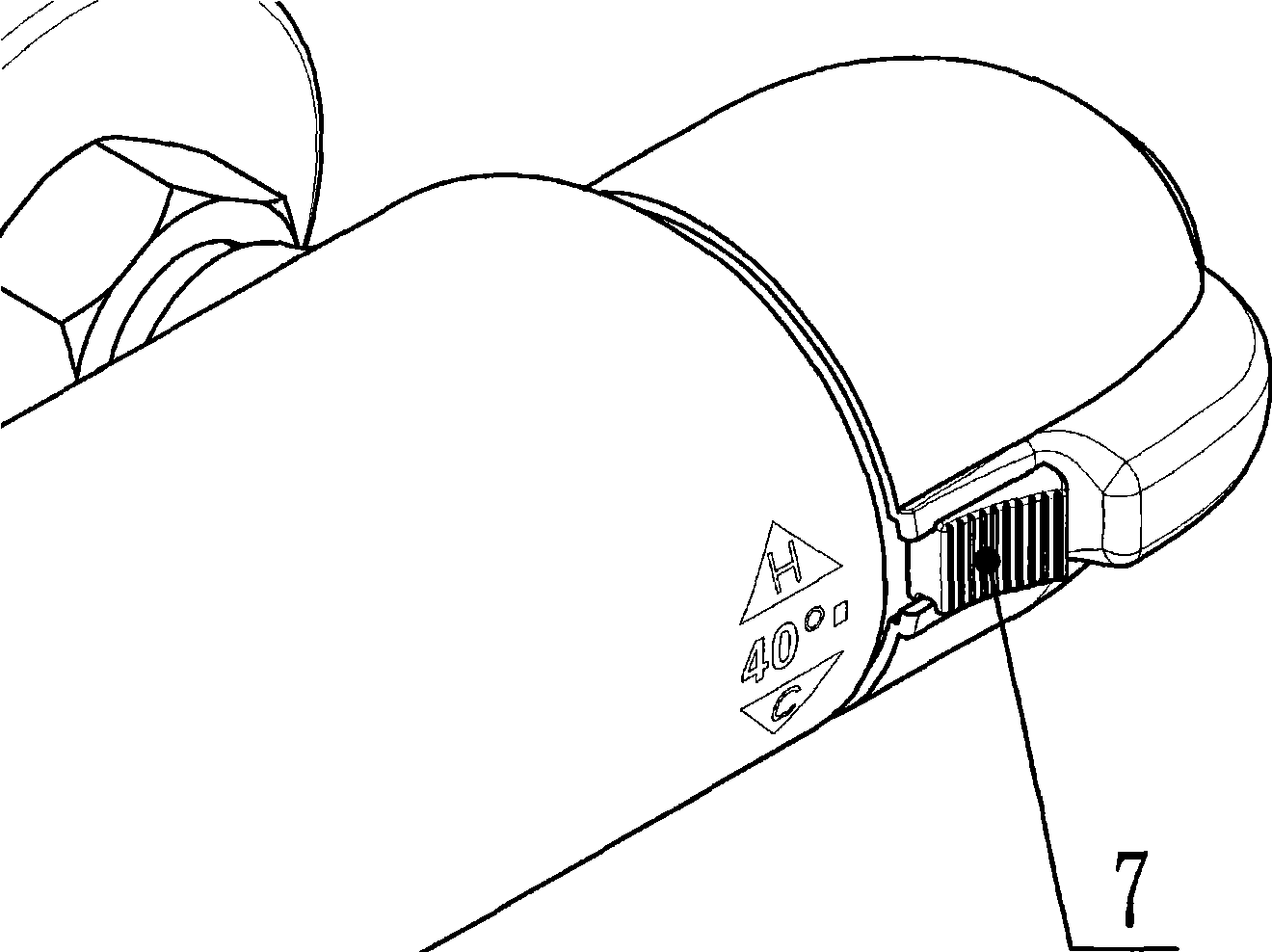

[0018] Such as figure 1 , figure 2 Shown: It is a schematic diagram of the structure of a traditional handle plus a button or a dial. 7 is a button or a dial. When the temperature needs to be adjusted, the button must be pressed or the dial is turned, and then the handle can be rotated to obtain the required temperature. This action Needs to act on two components, the handle and the button or toggle.

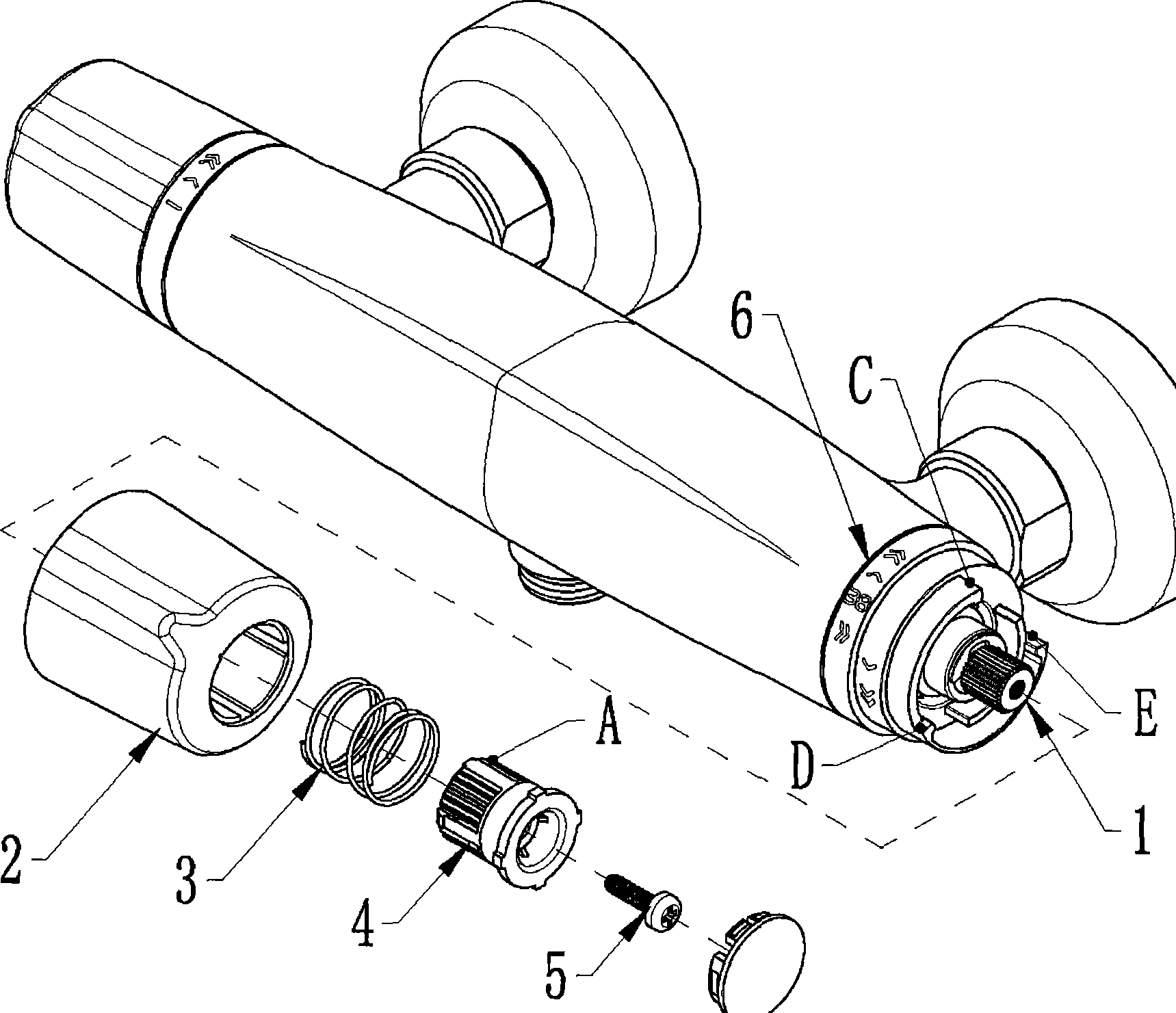

[0019] Such as image 3 As shown, the temperature adjustment handle structure includes: a thermostatic mandrel rod 1 , a handle 2 , a spring 3 , a joint 4 , a fixing screw 5 , and a stop ring 6 . The joint 4 is locked on the constant temperature mandrel rod 1 by the fixing screw 5, and the handle 2 and the joint 4 are matched through the gap between the key teeth, and the handle 2 can move horizontally on the key tooth A of the joint 4, and the handle 2 and the joint 4 are placed in the middle Spring 3. Three gears are set on the stop ring 6, which are the temperature upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com