Micro linear vibrator

A vibrator, linear technology, applied in electrical components, electromechanical devices, etc., can solve the problems of sparks, electromagnetic interference, easy wear, etc., and achieve the effects of low manufacturing cost, no sparks and electromagnetic interference, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

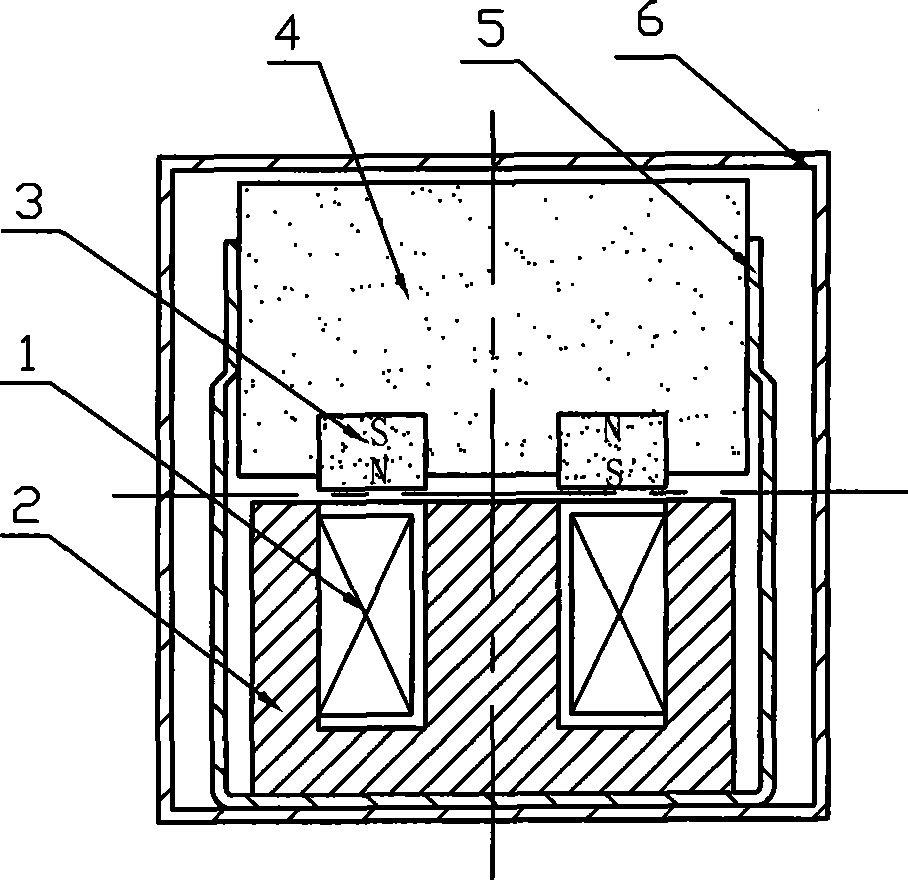

Embodiment 1

[0022] Such as figure 1 As shown, the miniature linear vibrator in this embodiment is composed of a coil 1, a mountain-shaped iron core 2, a magnetic steel 3, a vibrating body 4, a supporting frame-shaped reed 5 and a square shell 6, and the mountain-shaped iron core 2 is arranged on the shell 6, a coil 1 is wound on its central axis, and the two ends of the coil 1 are drawn out through wires. Above the mountain-shaped iron core 2, a vibrating body 4 and two magnetic steels 3 fixed therein by glue, the magnetic steel 3 Facing the two depressions of the mountain shape of the mountain-shaped iron core 2, the vibrating body 4 is connected to the shell 6 through the reed 5, and one N pole of the magnetic steel 3 faces downward, and the other N pole faces upward. The bottom edge of reed 5 is welded on the bottom of housing 6 inwalls, and mountain-shaped iron core 2, magnetic steel 3 and vibrating body 4 are all arranged in it, and 2 sides of supporting reed 5 are spot-welded with b...

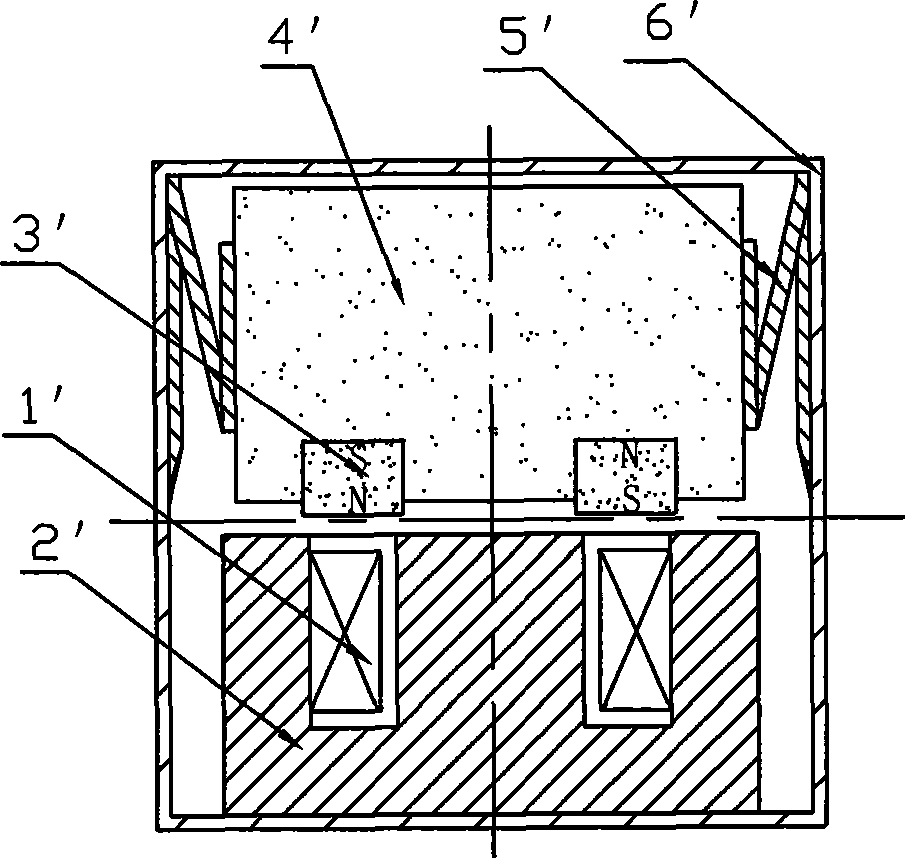

Embodiment 2

[0026] Such as figure 2 As shown, the miniature linear vibrator in this embodiment consists of a coil 1', a mountain-shaped iron core 2', a magnetic steel 3', a vibrating body 4', and a suspended "Z" shape on both sides above the vibrating body 4'. The reed 5' and the square shell 6' are composed, the mountain-shaped iron core 2' is arranged at the bottom of the shell 6', and a coil 1' is wound on its central axis, and the two ends of the coil 1' are drawn out through wires, and the mountain-shaped iron core 2' There is a vibrating body 4' and two pieces of magnetic steel 3' fixed therein by glue, the magnetic steel 3' is facing the two depressions of the mountain shape of the mountain-shaped iron core 2', and the vibrating body 4' is connected by a reed 5' In the shell 6', one N pole of the magnetic steel 3' faces downward, and one N pole faces upward. One end of the reed 5' is spot welded to the outer side of the vibrating body 4', and the other side is snapped to the midd...

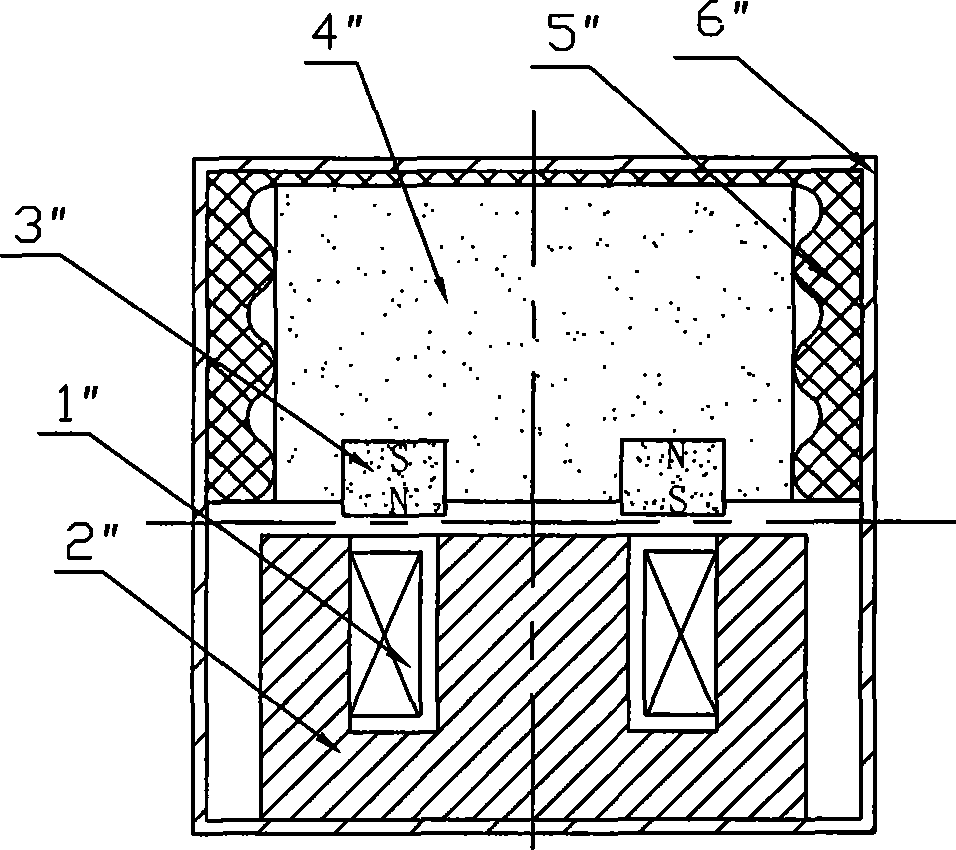

Embodiment 3

[0028] Such as image 3 As shown, the miniature linear vibrator in the present embodiment is composed of a coil 1 ", a mountain-shaped iron core 2 ", a magnetic steel 3 ", a vibrating body 4 ", a silicon rubber body 5 ", and a square shell 6 ", and the mountain-shaped iron core 2 " It is arranged on the bottom of the casing 6", and its central axis is wound with a coil 1". A piece of magnetic steel 3″, the magnetic steel 3″ is facing the two depressions in the mountain shape of the mountain-shaped iron core 2″, the vibrating body 4″ is connected to the shell 6″ through the silicon rubber body 5″, and the N pole of the magnetic steel 3″ is facing downward , a piece of N-pole facing upward. The silicone rubber body 5" fills the gap between the vibrating body 4" and the shell 6", and only needs to be connected between the two. It can be potted and can be wavy , and other shapes are also possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com