Tooth form subunit construction of tool

A component structure and tooth shape technology, which is applied in the field of tool tooth component structure, can solve the problems of affecting the degree of torque control, shortening the service life, and affecting the accuracy of torque control of hand tools, so as to reduce structural wear and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

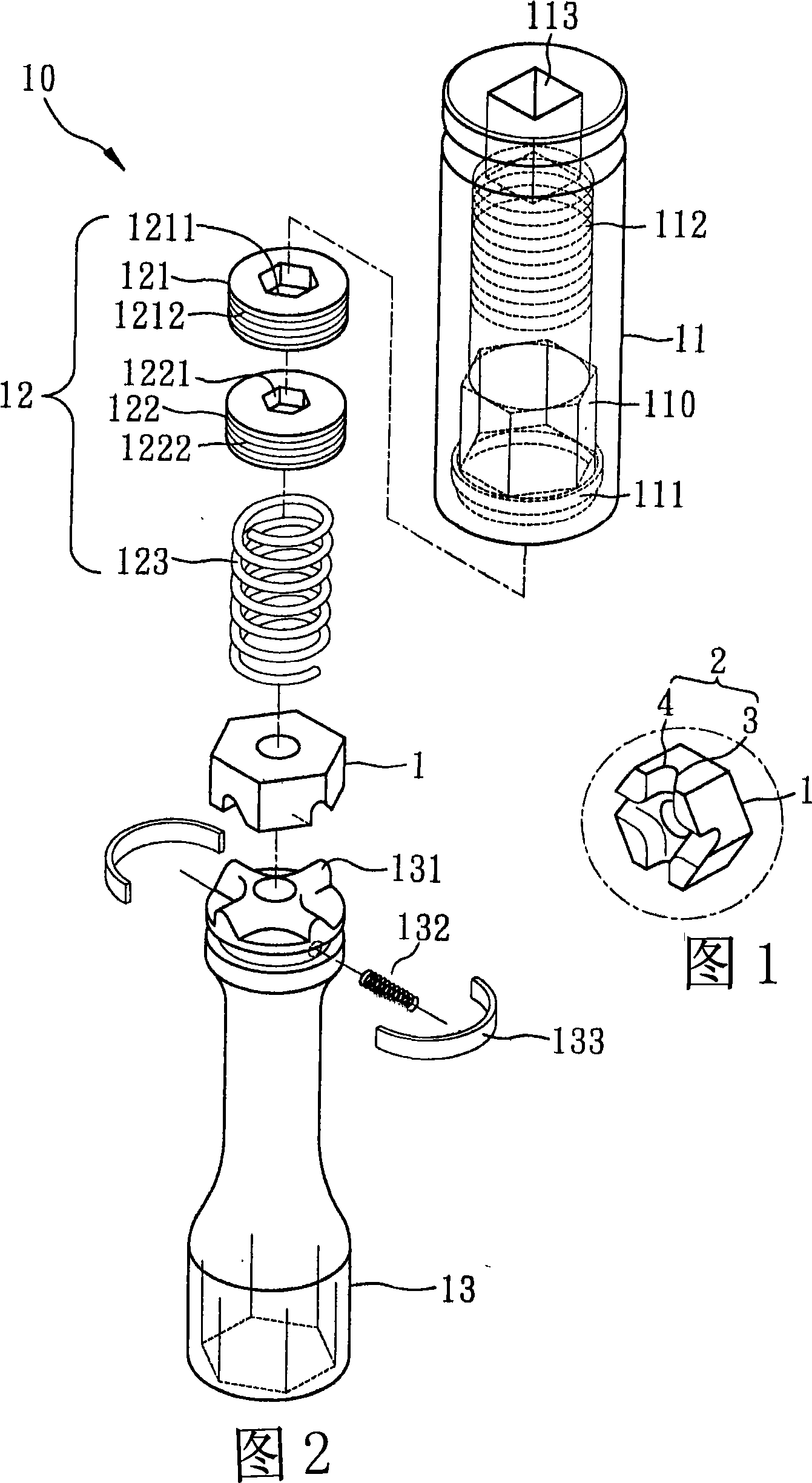

[0039] The present invention relates to a toothed part structure of a tool. Please refer to FIG. Formed by the intersection of a hypotenuse 3 and an arc 4, the angle between the hypotenuse 3 and the arc 4 is between 20 degrees and 55 degrees, and the tooth-shaped part 1 can be used in various types of torsion over controlled tools such as torque wrenches or torque drivers or torque adapters;

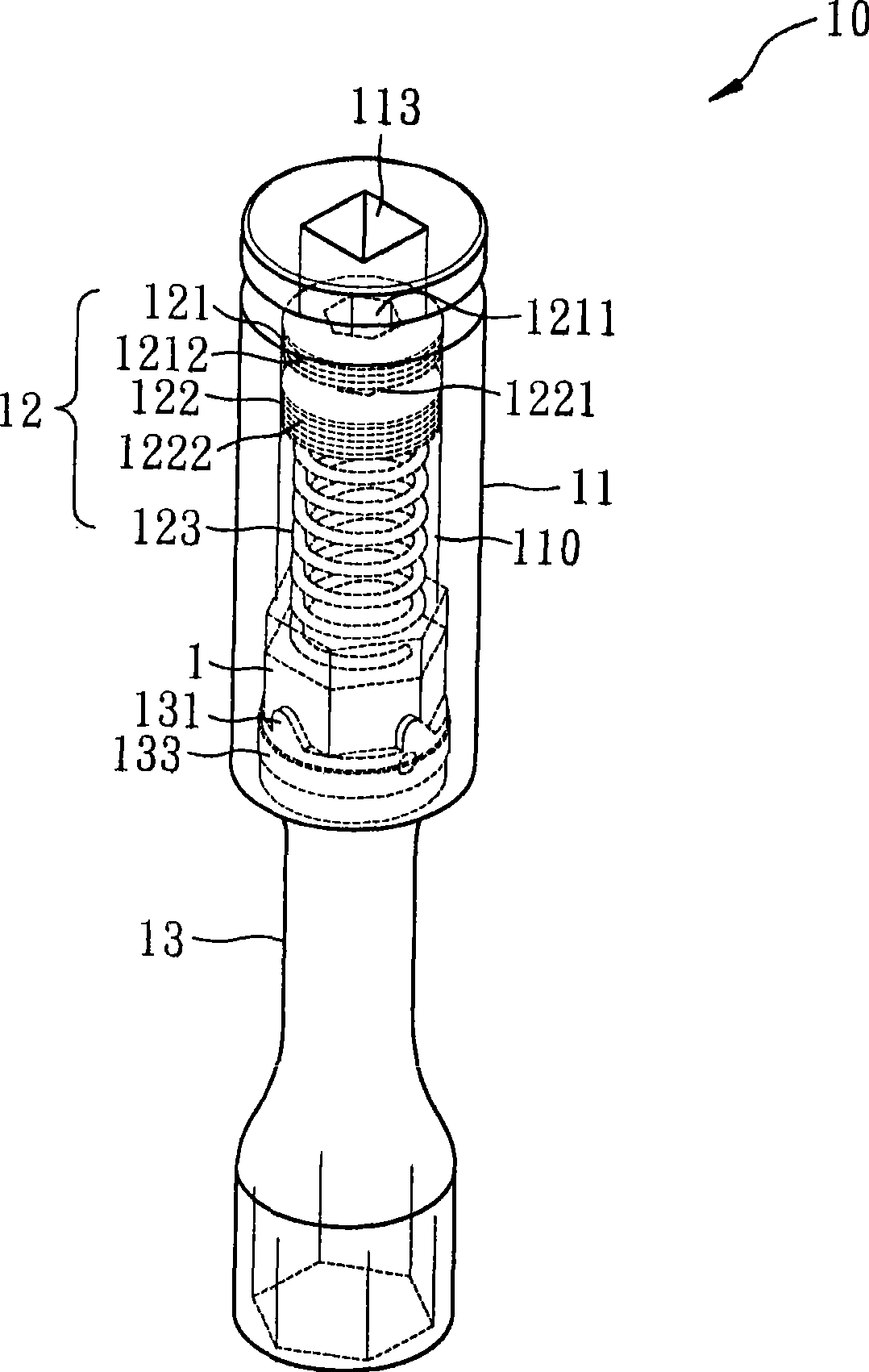

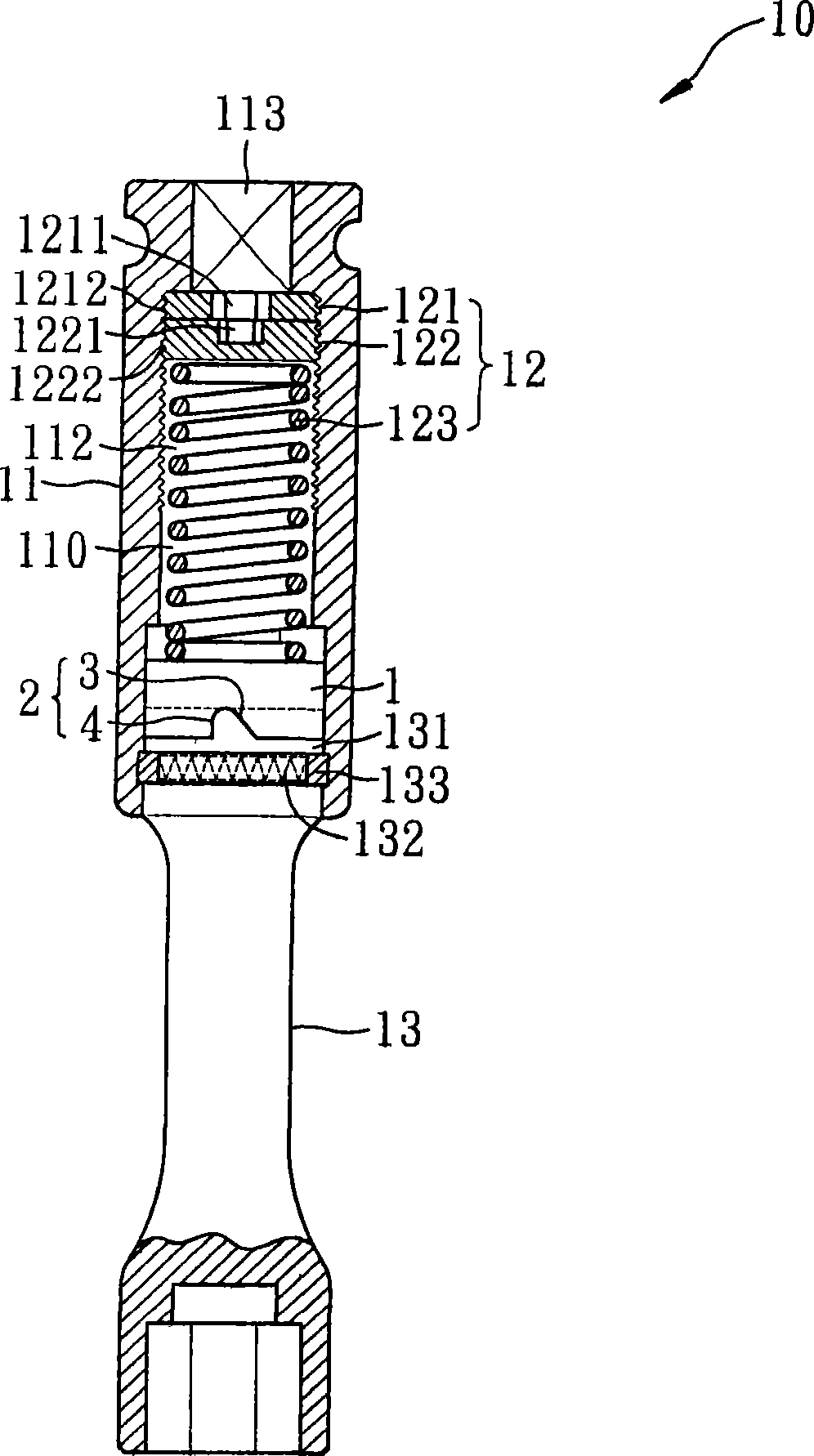

[0040] Please refer to Figure 2 to Figure 4 As shown, it is the first embodiment of the present invention, and the torque transfer tool 10 is used as an illustration:

[0041] The torque transfer tool 10 is provided with a shank 11, and a hollow accommodating portion 110 is provided in the shank 11. One end of the accommodating portion 110 forms a fitting section 111, and the other end forms a threaded section 112. The handle 11 is provided with a through hole 113, and the through hole 113 makes the accommodating part 110 be in a state of external communication. The handle part 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com